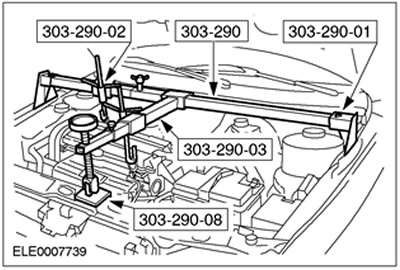

Special tool

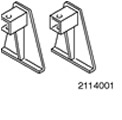

| Engine support beam 303-290A (21-140) |

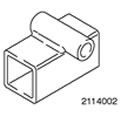

| Adapter for 303-290A (21-140) 303-290-01 (21-140-01) |

| Adapter for 303-290A (21-140) 303-290-02 (21-140-02) |

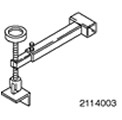

| Adapter for 303-290A (21-140) 303-290-03 (21-140-03) |

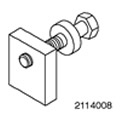

| Adapter for 303-290A (21-140) 303-290-08 (21-140-08) |

General equipment:

- Fixing clamps

- Jack for gearbox

| Name | Specification |

| Transmission fluid for automatic transmission | WSS-M2C202-B |

Installation

NOTE: The location of the engine mounts and engine mounts in the description corresponds to the view from the automatic transmission to the engine.

1.

CAUTION: The torque converter must remain at the correct installation depth throughout the entire installation procedure.

NOTE: Before installing any transaxle bolts to the engine, align the torque converter studs with the engine drive plate holes.

NOTE: The torque converter hub must be fully engaged with the oil pump drive gear.

Check the installation depth of the torque converter.

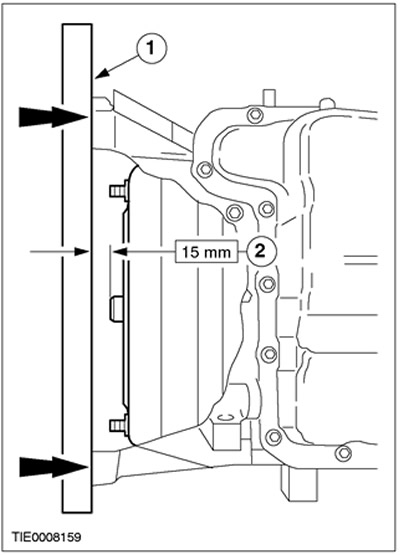

1. Attach a steel ruler to the flange of the automatic transmission in the block with the drive axle.

2. Check the installation depth by measuring the distance between the transaxle flange and the torque converter centering lug. The correct size is 15 mm.

2. Raise and support the vehicle. See Section 100-02 for more information.

3.

NOTE: Make sure the pins are installed correctly.

Secure the transaxle to the transaxle using suitable clamps on an appropriate transaxle jack and install the transaxle to the transaxle.

4.

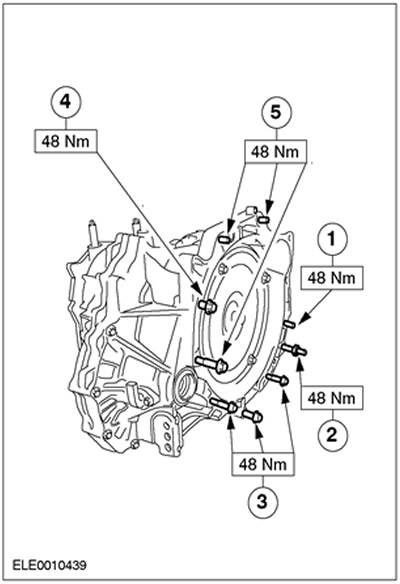

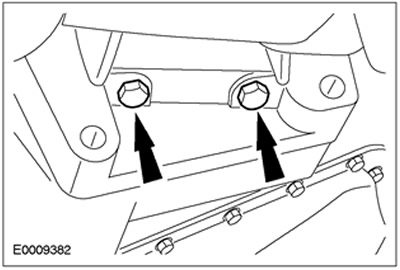

NOTE: Flange bolts vary in length.

Install the flange bolts.

- 1. M10 x 90.

- 2. M10 x 35 and M8 x 12.

- 3. M10 x 35.

- 4. M10 x 60.

- 5. M10 x 50.

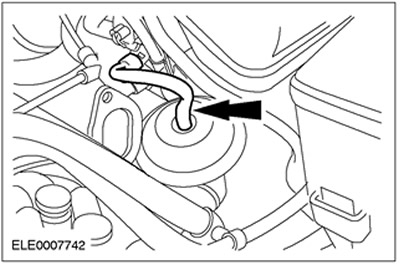

5.

NOTE: Install new torque converter mounting nuts.

Connect the torque converter to the engine drive plate (four nuts).

6. Install the torque converter cover (in the presence of).

7. Lower the car.

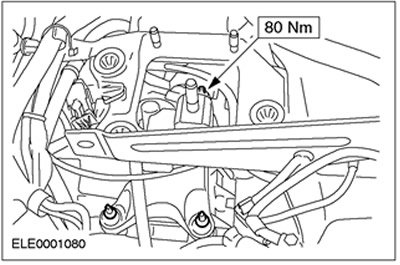

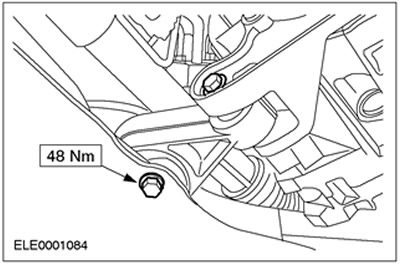

8. Install the rear engine mount bracket.

9. Install the rear engine mount.

10. Remove the special tools and remove the timber.

11. Raise and support the vehicle. See Section 100-02 for more information.

12.

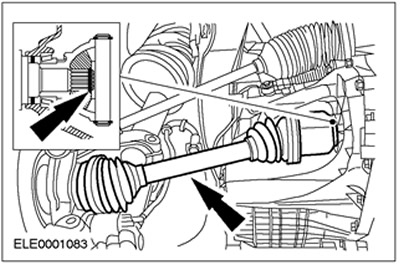

CAUTION: Support axle shaft. The inner hinge should not be tilted more than 18 degrees. External hinge - at an angle exceeding 45 degrees.

CAUTION: Be careful not to damage the axle shaft oil seal.

CAUTION: Make sure the snap ring is installed correctly.

NOTE: Install a new circlip.

Connect the left axle shaft to the gearbox in the block with the drive axle.

13.

CAUTION: Support axle shaft. The inner hinge should not be tilted more than 18 degrees. External hinge - at an angle exceeding 45 degrees.

CAUTION: Be careful not to damage the axle shaft oil seal.

Connect the right axle shaft to the gearbox in the block with the drive axle.

14.

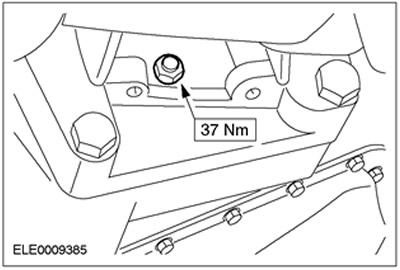

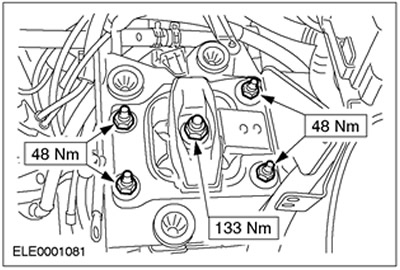

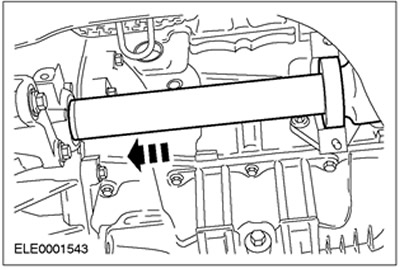

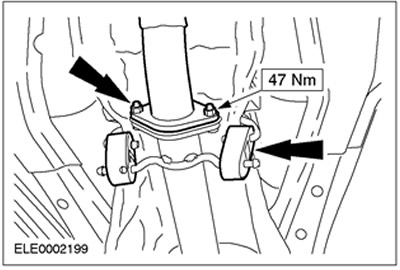

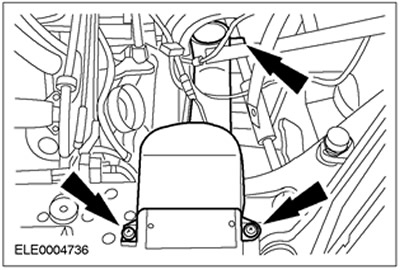

NOTE: Install a new intermediate shaft intermediate bearing cap and locknuts.

Establish a cover of the intermediate bearing of an intermediate shaft.

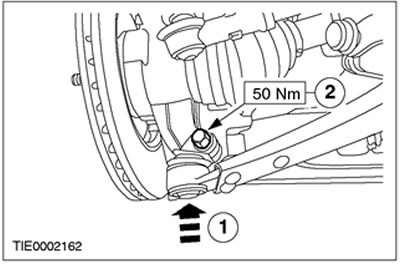

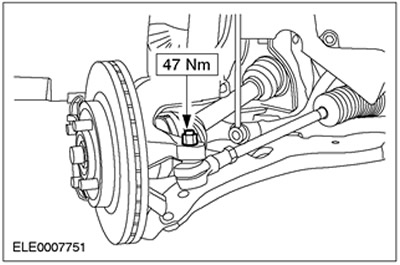

15. Connect the lower arms to the steering knuckles on both sides.

- 1. Connect the suspension arm ball joint.

- 2. Install the bolt.

16. Install the right engine roll limiter.

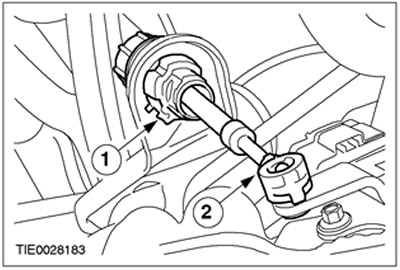

17. Connect the gear selector cable to the transaxle.

- 1. Connect the selector lever cable to the bracket.

- 2. Connect the gear selector cable.

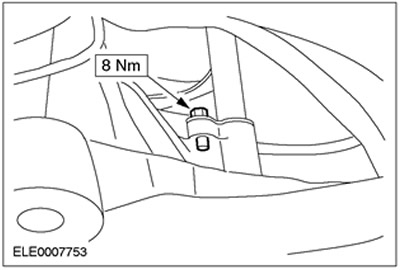

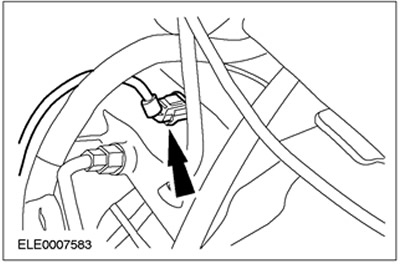

18. Connect the plug connector of the secondary shaft speed sensor (OSS).

19.

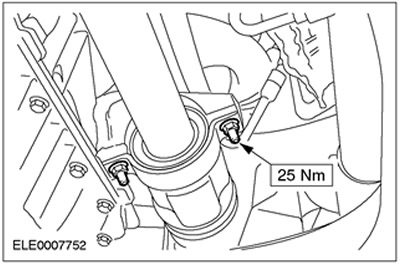

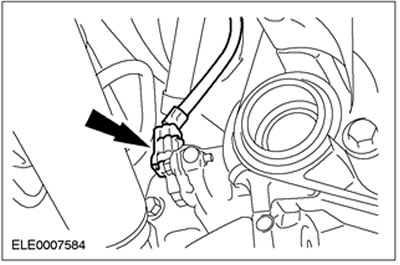

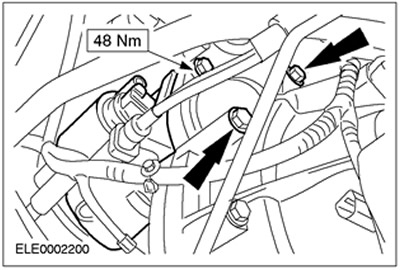

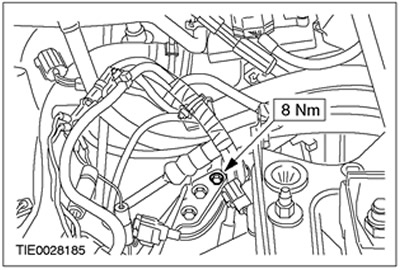

CAUTION: Use an open end wrench to keep the fluid line adapter from turning.

Install oil cooler lines.

20. Establish a tip of the left steering draft.

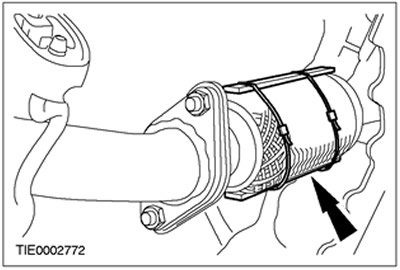

21. Screw in the starter bolts.

22. Connect the front exhaust pipe and three-way catalytic converter (TWC).

23. Remove the fixing collar.

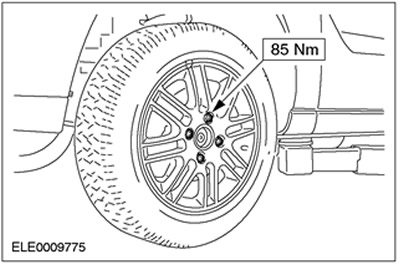

24. Install the left front wheel.

25. Lower the car.

26. Install the transmission fluid dipstick tube.

27. Install the transmission fluid dipstick tube bracket.

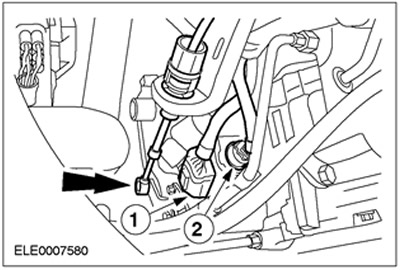

28. Match the electrical connectors and connect the select lever cable to the automatic transmission select lever in the drive axle assembly.

- 1. Gearbox range sensor plug (TR)

- 2. Plug connector for automatic transmission in the block with the drive axle.

29. Connect the plug connector of the turbine shaft speed sensor (TSS).

30. Install the air filter inlet pipe.

31. Adjust the transmission range select cable. See Section 307-05 for more information.

32. Connect the EGR vacuum line (EGR) to the EGR valve.

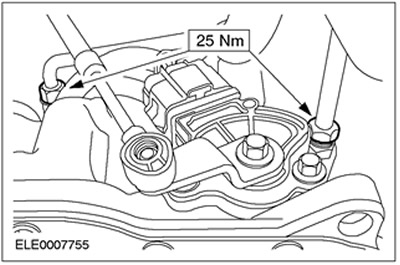

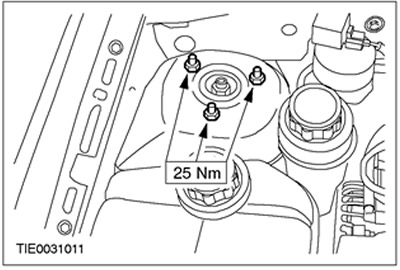

33. Tighten the nuts of the upper support of the suspension strut assembly with the spring (at both sides).

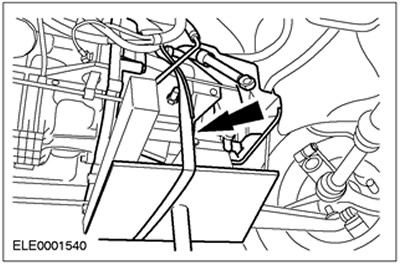

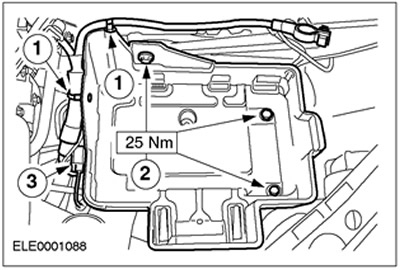

34. Install the battery tray.

- 1. Connect the wiring harness.

- 2. Screw in the bolts.

- 3. Connect the plug connector.

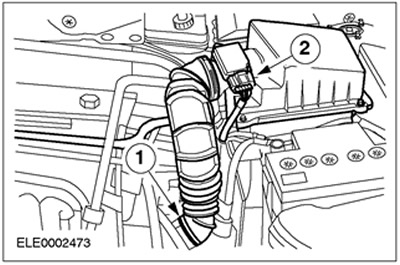

35. Install the air filter housing.

- Insert the air filter housing into the rubber bushings.

- 1. Connect the inlet hose.

- 2. Install the crankcase ventilation hose.

- 3. Connect the MAF sensor connector.

36. Install the battery. See Section 414-01 for more information.

37. Enter the radio key code.

38. Reprogram preset radios.

39. Set the clock.

40. Fill in the gearbox in the block with the drive axle transmission fluid.

41.

NOTE: Once the battery cables are disconnected and reconnected, some signs of abnormal vehicle control may appear as the vehicle learns its adaptive strategy. A car needs to travel at least 16 km to learn its working strategy (10 miles).

Final operations:

- After a road test, check the fluid level and correct if necessary.

- Check engine and cooling system for leaks (visual inspection).

Visitor comments