Special tool

| Air Pressure Test Panel and Gasket 307-412 |

| Pressure gauge 307-132 (17-014) |

Special tests have been developed to assist the technician in diagnosing the hydraulic and mechanical parts of the transaxle transaxle.

Check of frequency of rotation of a cranked shaft in an idling mode

Refer to PCED for information on diagnosing and checking idle speed.

Line pressure check

CAUTION: Line pressure checks should be performed before checking the engine speed limit. If the pressure in the line in the limit mode is low, do not check the limit speed, because. otherwise, damage to the transaxle unit will be aggravated. In any gear, do not hold the throttle fully open for more than five seconds.

NOTE: Failure of some sensors may cause PC, FMEM alarm action. Make sure that the self-test and electrical repairs have been performed, or the test results may be incorrect.

This check confirms that the line pressure is within specification.

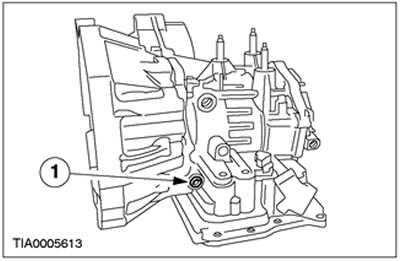

1. Connect a pressure gauge to the dedicated line outlet for pressure testing.

2. Start the engine and check the pressure in the line. To determine if line pressure is within limits, refer to the table below "Line pressure".

3. If the line pressure is not within specification, for information on line pressure problems, refer to "Line pressure diagnostic table".

| Pos. | Spare Part No | Name |

| 1 | - | Special outlet for checking line pressure |

Line pressure table

|

Gearbox |

Range |

Idle mode |

Limit mode |

||

|

kPa |

PSI |

kPa |

PSI |

||

|

4F27E |

P, N |

345-450 |

50-65 |

1240-1450 |

180-210 |

|

R |

450-585 |

65-85 |

1930-2310 |

280-335 |

|

|

D, 2, 1 |

345-450 |

50-65 |

1240-1450 |

180-210 |

|

Line pressure diagnostic table

| Test Results | Possible reason |

| Low pressure in all ranges | Worn out pump |

| Low pressure in all ranges | Fluid leakage from the pump, main control valve block or transaxle case |

| Low pressure in all ranges | The pressure control solenoid valve does not work. |

| Low pressure in all ranges | Solenoid control valve sticking. |

| Low pressure in D, 2 and 1 ranges only | Fluid leakage from the hydraulic circuit of the forward clutch |

| Low pressure range 2 | Fluid leakage from the intermediate/overdrive band brake hydraulic circuit |

| Low pressure only in ranges 1 and R | Fluid leakage from low/reverse clutch hydraulic circuit |

| Low pressure only in R range | Fluid leakage from reverse clutch hydraulic circuit |

| High pressure in all ranges | The pressure control solenoid valve does not work or the wiring harness is broken. |

| High pressure in all ranges | Stuck pressure regulator valve |

| High pressure in all ranges | PCM does not work. |

Checking the limiting speed of the crankshaft

This test checks the operation of the following items and the following parameters:

- torque converter clutches,

- forward clutch,

- single acting low gear clutch assy,

- dynamic characteristics of the engine.

WARNING: The parking brake must be fully applied for each test at the limit.

CAUTION: Always perform a line pressure test before checking the engine speed limit. If the pressure in the line in the limit mode is low, do not check the limit speed, because. otherwise, damage to the transaxle unit will be aggravated.

NOTE: The speed limit check should be performed with the engine and transaxle at normal operating temperature.

1. Connect a tachometer to the engine.

CAUTION: After checking each of the following ranges: D, 2, 1, and R, move the gear selector to N (NEUTRAL) and let the engine run at 1000 rpm for approximately 15 seconds to allow the torque converter to cool down before checking the next range.

CAUTION: In any gear, do not hold the throttle fully open for more than five seconds.

CAUTION: If the engine speed measured by the tachometer exceeds the maximum prescribed value, immediately release the accelerator pedal. Exceeding indicates slippage of the clutch or band brake.

NOTE: Prolonged use of this procedure may cause DTC P0712, P1783 to set. After performing the speed limit check, perform an OBD check and clear the DTCs from the memory.

2. Press the accelerator pedal to perform WOT (wide open throttle position) in every range. Record the RPM reached in each range. The speed limits must be as follows:

Engine speed limit table

| Engine | rpm |

| 1.6L | 2300 - 2650 |

| 2.0L | 2439 - 2837 |

3. If the speed limit values were too high, refer to the following Speed Limit Diagnostic Chart. If the speed limits were too low, check the idle speed first. If the engine idle is normal, remove the torque converter and check the torque converter single acting clutch for slippage.

Table for diagnosing the maximum speed of the crankshaft of the engine

| Gear selector position | Possible reason |

| Above normal in position "D", "2" And "1" | Forward clutch slip |

| Above normal in position "2" | Intermediate/Overdrive Band Brake Slip |

| Above normal in position "1" And "R" | Low/Reverse Clutch Slip |

| Above normal in position "R" | Reverse clutch slip. |

| Above normal in position "R" | Carry out a road test to determine if the problem is with the low/reverse clutch. |

| Above normal in position "R" | The low/reverse clutch is defective. |

Air pressure tests

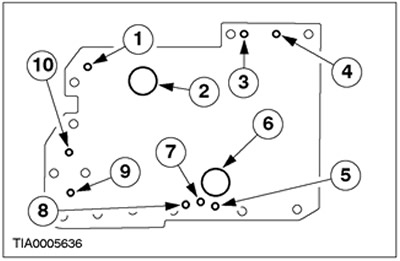

Panel for checking the air pressure of the gearbox in the block with the driving axle

| Pos. | Spare Part No | Name |

| 1 | — | Release the servo |

| 2 | — | Activating the servo |

| 3 | — | Direct Clutch Engagement |

| 4 | — | Reverse clutch engagement |

| 5 | — | Torque converter bypass |

| 6 | — | Low/Reverse Clutch |

| 7 | — | Feed to the torque converter |

| 8 | — | Engaging the forward clutch |

| 9 | — | Activating the servo drive |

| 10 | — | Engagement of the forward drive servo drive. |

A no-motion condition may exist even with correct fluid pressure in the transaxle due to faulty clutches and band brakes. Chaotic switching can be found by running a series of checks with air pressure instead of fluid pressure, which will determine the location of the fault.

Follow the prescribed procedure to determine the location of a faulty clutch or band brake by applying air pressure to the various ports on the test panel.

NOTE: Use only dry, stabilized air with a maximum pressure of 3 bar.

Supply air to the corresponding port (am). When the element is activated, an indistinct thud should be heard or some movement may be felt. When the element is fully engaged, there should be no whistling sound.

1. Drain the transmission fluid from the transaxle and remove the transmission fluid oil pan. For more information refer to Oil Sump, Gasket and Filter available in this section.

2. Remove the main control valve block. For more information, refer to the Main Control Valve Assembly available in this section.

3. Install the gearbox test panel and gasket. Use the gearbox oil sump bolts to secure the inspection panel. Tighten the bolts to 10 Nm.

4. Supply air to the corresponding coupling port) (refer to picture). If there are leaks in the coupling seals or check ball valves, hissing may be heard. If coupling seals or ball valves are leaking, a whistle may be heard.

If the test results show that the servos are not working, take them apart, clean and inspect to find the source of the problem.

If the air pressure supplied to the coupler ports fails to engage the coupler, or another coupler engages at the same time, disassemble the assembly and use air pressure to check the passages in the center support and the couplers for blockages.

Visitor comments