Attention: If the valve actuator parts are to be used again, they must be installed in their original places. In order not to confuse the parts in places, you should prepare a laying board for their removal.

Withdrawal

Remove the air filter see p. 57.

Remove cylinder head cover.

Remove toothed belt see from 13.

Turn the engine crankshaft so that none of the pistons is at TDC, see from 13.

Unscrew the 3 mounting bolts and remove the oil spray pipe.

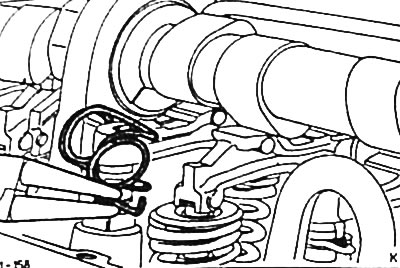

Detach the retaining springs of the pressure levers from the clips on the spherical pins and remove.

Pull push levers away from camshaft. To do this, turn the camshaft so that the corresponding valve spring is unloaded. Insert the tool FORD 21-005B between the camshaft and the upper plate of the valve spring and sink the plate so that the pressure lever can be removed.

Attention: keep an eye on those. so that the valve cotters do not loosen and the valve does not fall into the combustion chamber. If this happens, the cylinder head will need to be removed.

If a spring compressor is not available, the valve spring can be carefully compressed with a screwdriver.

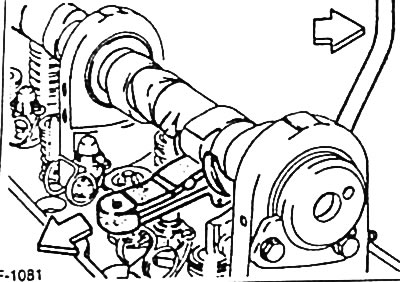

Unscrew the central bolt of the camshaft gear and remove the gear with the thrust plate. At the same time, hold the camshaft with a wrench by the lug located behind the sixth cam.

Loosen the camshaft setting plate and carefully remove the camshaft towards the rear.

From the toothed belt side, carefully pull the camshaft oil seal out of the cylinder head.

Installation

At the service station, the camshaft can be checked for runout if necessary.

The camshaft, its bearings and mounting plate are easily lubricated with SAE 80/90 hypoid oil (transmission oil).

Carefully insert the camshaft from the rear bearing side.

Caution: Do not damage the running surfaces of the bearings.

Insert and screw down the mounting plate.

If a used camshaft of a car with high mileage is installed, then the axial clearance must be measured. In the service station, a linear displacement indicator is used for this, which is attached to the cylinder head. Press the camshaft towards the toothed belt and set the value on the indicator scale "0". Then press the camshaft towards the mounting plate and read the reading on the indicator scale. The prescribed value is 0.05-0.204 mm.

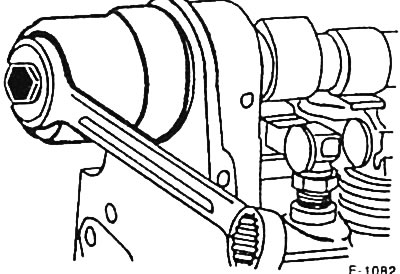

It is easy to lubricate the sealing lips of the new camshaft oil seal with gear oil and insert the oil seal using the FORD special tool 21-009B. The gland should be located in the hole 1.5 mm deeper than its edge. If a special tool is not available, drive in the stuffing box using a pipe having the same outer and inner diameters as the stuffing box.

Fit camshaft sprocket and tighten bolt to 50 Nm. While doing this, hold the camshaft with a wrench.

Attach and screw on the oil spray pipe.

Set the camshaft gear to the TDC mark for the piston of cylinder 1, see p. 17.

Align the crankshaft to the TDC mark for the piston of cylinder 1, see p. 17.

Slightly sinking the plates of the valve springs, insert the pressure levers.

Attention: Reinstall pressure levers in their original places.

Attach the retaining springs of the pressure levers and fasten them to the clamps. In this case, the clamps must be located on the side of the camshaft.

Install toothed belt see p. 13.

Check and, if necessary, adjust the clearances in the valve drive, see p. 26.

Install the cylinder head cover see p. 15.

Install the air filter.

Visitor comments