Attention: Operations and instructions applicable to all engines are described above in chapter for the ONS engine. This chapter highlights only the significant differences.

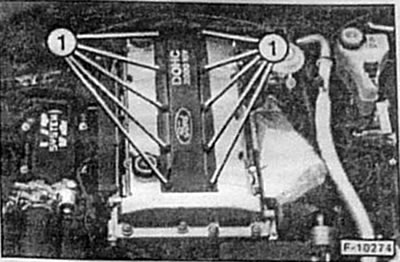

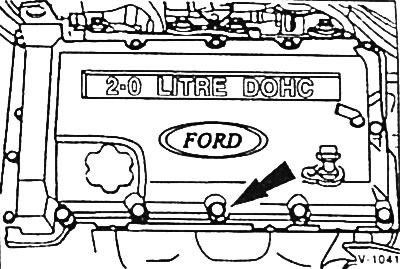

All illustrations refer to 2.0L DOHC engine.

Disconnect the fuel lines by pushing in the tabs.

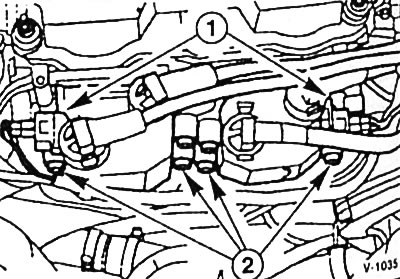

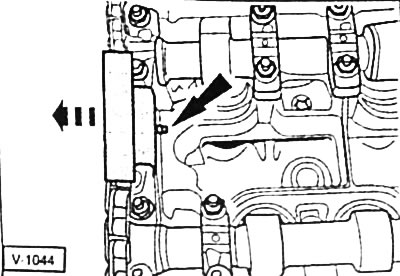

Remove ignition coils. To do this, unplug 2 connectors -1-, unscrew 6 bolts -2- and pull high voltage wires out of the plug.

16V engine: Loosen ignition coil cover -1-. Two ignition coils are located respectively above the second and fourth cylinders. Remove the tips of the spark plugs, unscrew the 2 mounting bolts for each coil and remove the coils.

Unscrew the guide tube for the engine oil level indicator and pull it out towards the top.

Remove 11 bolts and 4 nuts securing cylinder head cover.

Loosen the top cover of the chain drive.

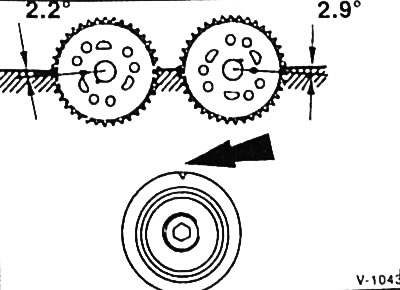

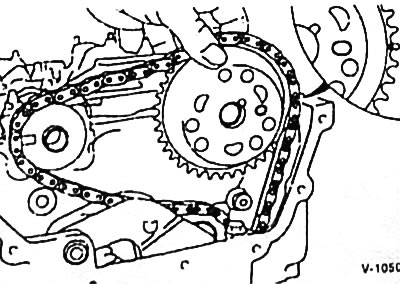

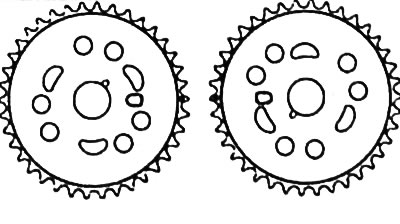

Turn the crankshaft until the piston of cylinder 1 is at TDC of the combustion process, see illustration. crankshaft rotation outlined us. 13.

Loosen the top chain guide.

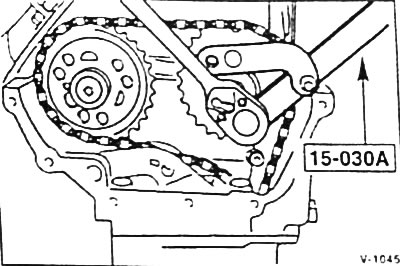

Loosen the camshaft sprocket bolts. At the same time, hold the sprockets with the FORD 15-030A tool.

Using a waterproof felt-tip pen or marker, draw a line through each sprocket and drive chain to mark the position of the chain relative to the sprockets for reassembly.

Remove camshaft sprockets. Make sure that the drive chain does not fall into the chain drive shaft. Suspend the drive chain to the side with a wire so that it does not interfere with further dismantling.

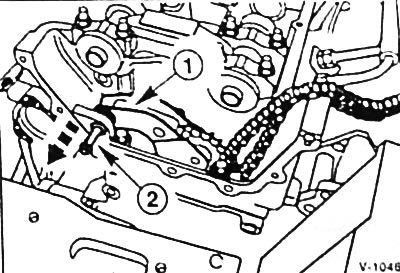

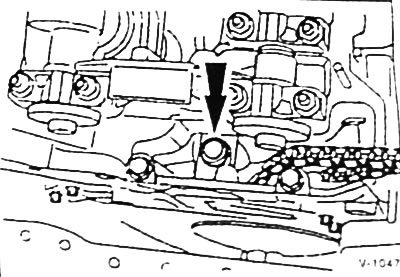

Remove retaining ring -1- from support pin -2- using pliers.

Caution: The circlip must not fall into the chain drive shaft. Put a clean rag down!

Screw an M6 bolt into the bearing pin -2- and unscrew the pin.

Remove the chain tensioner lever from the chain drive shaft.

Remove the chain tensioner hydraulic tappet from the cylinder head and discard.

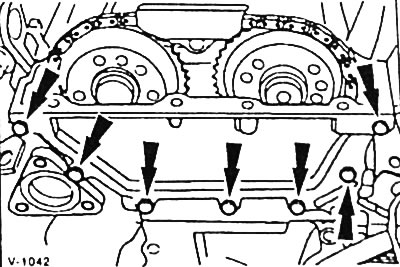

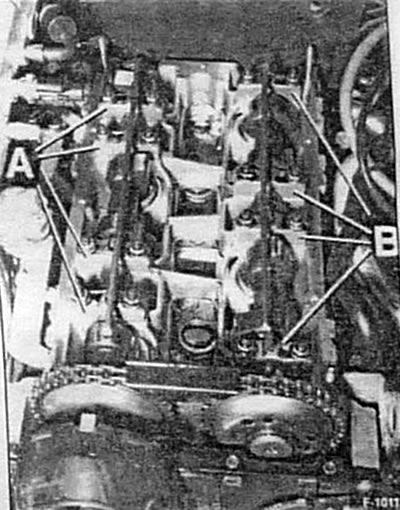

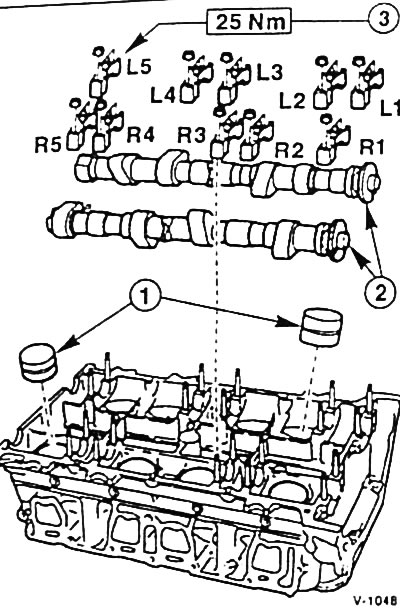

Loosen evenly and remove bearing caps -A- for intake camshaft and bearing caps -B for exhaust camshaft.

Attention. The camshaft bearing caps are marked, for example L3, and must not be interchanged or replaced.

Remove camshafts.

Remove hydraulic valve lifters.

Attention: Before loosening the bolts, make sure that the cylinder head has cooled down to at least +30°C.

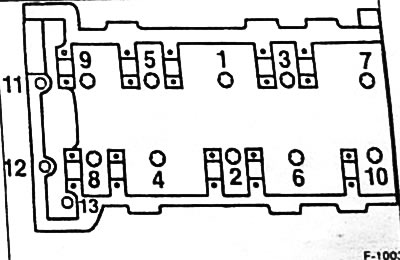

First, unscrew additional bolts 11, 12 and 13 with internal slots in the head.

After that, loosen the bolts with internal splines in the head in the sequence from 10 to 1 for the first step by about 1/2 turn, for the second step - by one full turn and for the third step, unscrew the bolts completely.

Installation

Note: To ensure flatness, the cylinder head may be remachined no more than 0.3 mm. The height of the machined head must not be less than 147.45 mm, and the height of the combustion chamber must not be less than 13.8 mm.

Lay the new cylinder head gasket without sealant over the guide bushes so that it does not block any holes.

Attention: To avoid damage to the pistons and valves, before installing the cylinder head, turn the crankshaft so that the piston of cylinder 1 is approximately 25 mm below TDC. Once the cylinder head and camshafts have been installed and the camshafts have been set to TDC, the crankshaft must be rotated back to the position where the piston of cylinder 1 is at TDC.

Attach cylinder head.

New fastening bolts in the area of heads and threads are easy to lubricate and tighten by hand until they stop.

Caution: The cylinder head bolts must be replaced. Insert M11 boots into holes 1 to 10, insert two long M8 bolts into holes 11 and 12, and insert a short M8 bolt into hole 13.

Tighten the M11 cylinder head bolts in 4 steps. In each step, the bolts are tightened in sequence from 1 to 10.

- Reception 1: using a torque wrench with a torque of 40 Nm.

- Reception 2: using a torque wrench with a torque of 55 Nm.

- Technique 3: Using a locked torque wrench, tighten by 90°.

- Technique 4: Using a locked torque wrench, tighten by 90°.

Attention Bolts of fastening of a head of cylinders after a certain run are not tightened.

Tighten new bolts M8 -11/12/13- from the end face of the cylinder head to 40 Nm.

Note: at the workshop, the camshafts can be checked for runout if necessary.

Camshafts and their bearings are easy to lubricate with engine oil.

By the position of the crankshaft pulley, check whether the piston of cylinder 1 is approximately 25 mm from TDC.

The valve tappets -1- are easy to lubricate and install in their original places in which they were before removal.

Set the camshafts -2- to approximately the TDC of cylinder 1, so that the camshafts on the sprocket mounting side are outward.

Caution: Do not damage the running surfaces of the bearings. R - intake side, L - exhaust side. The intake camshaft is identified by two identification rings located between the fourth and fifth cams.

Position bearing caps -3- for camshafts in accordance with markings on them and tighten caps evenly to 25 Nm. At the same time, also tighten the fastening of the upper guide of the chain drive.

Attention: After tightening the camshaft bearing caps and installing the drive chain, the crankshaft can be rotated no earlier than after 15 minutes. During this time, the hydraulic pushers settle. If this time is not maintained, the valves and/or pistons may be damaged.

If a used camshaft is installed, the axial clearance must be measured. At service stations, a linear displacement indicator is used for this, which is attached to the cylinder head Press the camshaft towards the chain drive and set the value on the indicator scale "0". Then press the camshaft in the opposite direction and read the indication on the indicator scale. The prescribed value is 0.02-0.26 mm.

Set the camshafts and the crankshaft to the TDC position for the piston of cylinder 1.

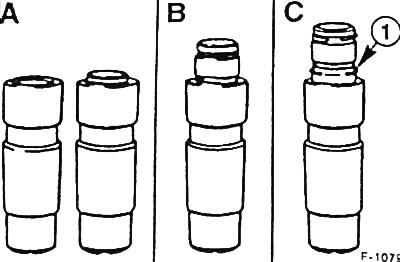

Attention: Only a new, fixed hydraulic tappet -A- must be installed. The partially or completely unlocked hydraulic tappet -B/C- must be disposed of.

Carefully install the fixed hydraulic tappet into the cylinder head with the piston up.

Caution: Risk of injury!

Insert the chain tensioner lever.

Insert the support pin into the hole and secure with the circlip.

Caution: The circlip must not fall into the chain drive shaft. Put a clean rag down!

Place the drive chain on the exhaust camshaft sprocket so that the marks made before removal match. The copper links should cover the mark on the sprocket. Pulling at the same time (long) the side of the chain must be tight and the camshaft sprocket must be in the TDC position for the piston of cylinder 1 (see drawing V-1043). Tighten the fastening of the sprocket to the camshaft firmly by hand; if necessary, turn the camshaft by the raw side with pliers so that the sprocket is fixed on the camshaft.

Install the drive chain and intake camshaft sprocket in the same way.

Note: There should be some slack in the drive chain between the camshaft sprockets.

Turn the crankshaft clockwise until the intake camshaft begins to turn.

For hydraulic tappet with piston protrusion (in figure F-1079 it is the 2nd piston on the left) Unlock the piston by pushing the tension lever down with your hand.

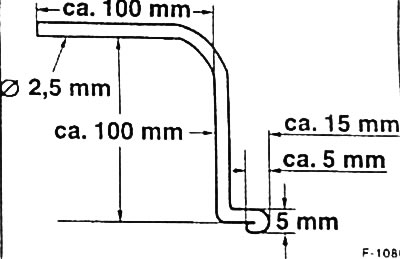

For hydraulic tappet without piston protrusion (in figure F-1079 it is the 1st piston on the left) unlock the piston using a tool made by yourself from a welding electrode with a diameter of 2.5 mm in accordance with figure F-1080.

Using a screwdriver, carefully lift the chain tensioner arm and insert a tool between the chain tensioner arm and the piston. Remove the screwdriver and, pressing down the tension lever by hand, unlock the piston. Remove device.

Holding the camshaft sprockets with the FORD 15-030A special tool, tighten their fastening to 60 Nm.

Rotate the engine crankshaft in the direction of rotation by one turn. The marks on the camshaft sprockets must face each other at the level of the top edge of the cylinder head.

Turn the crankshaft of the engine in the direction of its rotation one more revolution and check whether the piston of cylinder 1 is at TDC (see drawing V-1043). If the adjustment is incorrect, the hydraulic tappet must be removed and reinstalled again.

Attach the new plastic chain guide to the holder.

Attach the top drive chain cover with a new seal and tighten the cover fastening to 10 Nm. Align the upper edge of the cover at the sealing surface of the cylinder head. Maximum downward displacement: 0.13 mm.

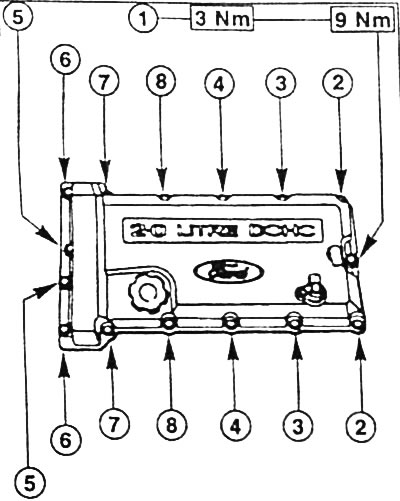

Attach the cylinder head cover with a new gasket and tighten the 11 bolts and 4 nuts of the cover in the sequence shown, first to 3 Nm and then to 9 Nm.

Tighten guide tube for oil level indicator to 20 Nm.

Tighten ignition coil mounting to 10 Nm.

Visitor comments