Withdrawal

1. Remove intake manifold (section 8).

2. Remove the exhaust manifold (section 9).

3. As recommended in Section 3 remove the valve cover.

4. Drain the cooling system. Disconnect the radiator hose from the thermostat housing on the left side of the engine. Disconnect the wire of the temperature sensor, unscrew the nut that secures the negative wire to the thermostat housing and pull out the wire of the temperature switch of the electric fan located in the head of the unit directly under the thermostat housing) (see chapter 3).

5. Unscrew the bolt of the ignition coil-to-head bracket, loosen the bracket-to-block bolt and turn the bracket forward (see chapter 5).

6. Remove cover and distributor wires (see chapter 5).

7. Remove drive belt (Chapter 1).

8. Unscrew the bolt of the dipstick tube bracket for measuring the oil level in the engine (see picture).

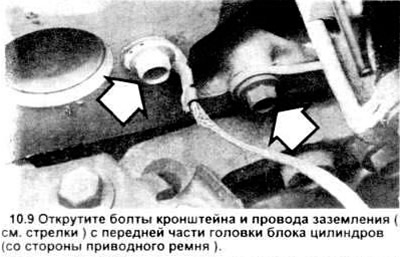

9. From the front end of the cylinder head (drive belt end) unscrew the bracket bolts (see picture).

10. Remove valve levers and push rods (section 4).

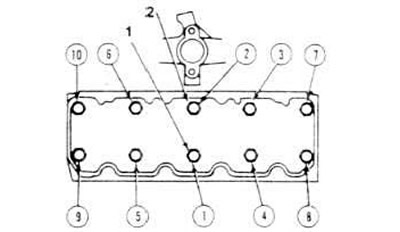

11. Unscrew the head bolts, adding 1/4 turn until. as long as they can be rotated by hand. Go from bolt to bolt in reverse tightening sequence as shown in Figure 10.17. Remember that the rear bolts are longer than the front ones - all of them must be installed strictly in their places.

12. Separate the head from the block. If it sticks, gently pry the front of it off using the motor mount as a fulcrum (see picture).

Caution: do not try to move the head in any other place with the lever, you will damage it.

Installation

13. The contact surfaces of the cylinder head and block must be perfectly clean before installing the head. Use a scraper to remove any soot and scrape off the old gasket residue, then clean the mating surfaces with lacquer thinner or acetone.

If oil remains on the surfaces when installing the head, the gasket will not sit tightly and there will be leaks. When working with the block, fill the cylinders with a special clean rag to avoid dust and dirt. Use a vacuum cleaner to get rid of debris and dirt trapped in the cylinder.

14. Check the contact surfaces of the block and head for deep scratches, dents and other damage. If the damage is minor, it can be repaired with a file; if it is serious enough, then machining is needed.

15. Using a tap of the appropriate size, go through the threaded holes for the bolts. Place each bolt in a vise and go over the threads with a hammer to remove corrosion and restore the threads. Dirty, corroded, damaged threads distort torque readings.

16. Since there are no alignment pins on the head, make sure the gasket is aligned after installing the head.

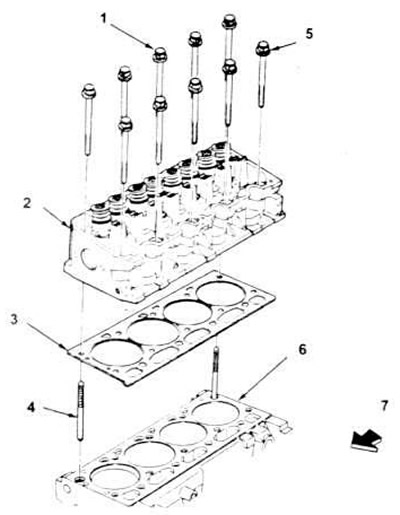

17. Lower the cylinder head onto the block. Install the cylinder head bolts in their sockets and tighten with your fingers Tighten the bolts in two steps to the required torque, following the order shown (see picture).

10.17 a. Installation procedure for the cylinder head.

1. 5 bolts M11x1.5x100.

2. Cylinder head assembly.

3. Gasket.

4. 2 guide bolts.

5. 5 bolts M11x1.5x80.0.

6. Cylinder block.

7. Front of the engine.

10.17 b. Cylinder head bolt tightening sequence - remember that the front bolts are shorter than the rear bolts.

1. 5 bolts M11x1.5x100.

2. 5 bolts M11x1.5x80.0.

18. Installation is carried out in the reverse order of disassembly.

Visitor comments