Note: This procedure is described on the assumption that the engine is inside the vehicle. If the engine is removed, then simply unscrew the pan bolts and remove it from the engine block.

Withdrawal

1. Disconnect the negative battery cable.

2. Raise the vehicle and place it on stands.

3. Drain the oil (see if necessary chapter 1).

4. Drain the coolant (see chapter 1).

5. If the vehicle is equipped with a manual transmission, remove the engine wobble limiter (see picture).

6. Remove the starter (see chapter 5).

7. Remove the exhaust elbow between the intake and exhaust manifolds and the catalytic converter (see chapter 4).

8. Disconnect the cooling tube connected to the lower radiator hose, the water pump and the locking tabs on the oil pan (see chapter 4).

Warning: To avoid possible splashing of coolant into your eyes, do not stand or lie directly under the area between the coolant tube and the lower radiator hose. Residual coolant may splash out when these parts are separated.

9. If the vehicle is equipped with an air conditioning system and / or power steering, remove the compressor / power steering belt, remove the compressor from the bracket and disconnect the bracket from the unit (see chapter 3). Move aside the lower tubes of the air conditioning system. remove completely if necessary.

Warning: Do not disconnect the A/C hoses.

10. Remove the oil pan bolts (see picture). Remember that the two bolts located in the cavity of the access to the cover are larger than the others.

11. The oil pan can be difficult to remove due to the use of sealant in it. Do not try to pry it with a lever. Use a large rubber mallet to pry it off.

Installation

12. Use a special gasket scraper to clean all traces of the old gasket and sealant from the sump and block. Wipe the surfaces under the gasket with a cloth soaked in acetone or lacquer thinner.

14. The oil pump tube and strainer assembly should also be cleaned. After cleaning both parts, install them (see next section).

15. Apply a thin coat of GE Pressure Sensitive Adhesive to the gasket mating surfaces of the engine and to the new block side oil pan gasket.

Warning: Use adhesive only in a well ventilated area.

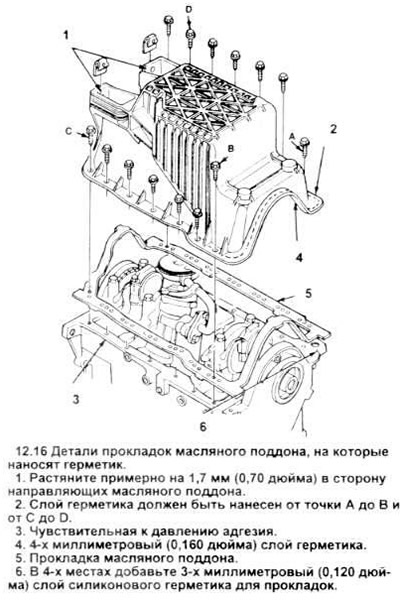

16. After adhesion has set, apply a 1/8" thick coat of RTV Sealant to the connections between the front cover and the block, and between the block and the rear seal retainer (4 seats) (see picture).

17. Immediately lower the shim onto the block and press it down to align "pillow" (layer) RTV sealant. previously applied in accordance with clause 16.

18. Apply a layer "pillow" 5/32" thick RTV Sealant to the mating curved surfaces at the edges of the sump. The layers should go from one corner bolt to the other.

19. A couple of minutes after making the layers ("pillows") install the oil pan.

20. Install the bolts on the oil pan flanges and tighten them so. so that the sealant compresses until the holes in the oil pan are aligned with the holes in the gearbox housing; however, the pallet must be able to move slightly relative to the block.

21. Install and tighten to the torque value specified in the specification two bolts securing the oil pan to the gearbox until the pan is axially aligned with the box, then loosen the bolts 1/2 turn.

22. Tighten all bolts on the oil pan flanges to the specified torque.

23. Tighten the two bolts securing the oil pan to the gearbox to the specified torque.

24. Subsequent installation is carried out in the reverse order of disassembly.

Visitor comments