Special tool

| Universal wrench for holding flanges 205-072 (15030A) |

| Oil Seal Remover 303-039 (21-009V) |

| Engine lift tool 303-122 (21068A) |

| Socket wrench for cylinder head bolts 303-392 (21-167) |

| Pliers for spark plug connectors 303-622 (21-226) |

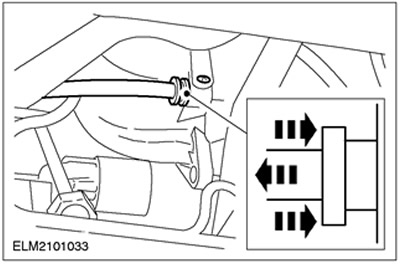

| Radiator hose clamp remover and installer 303-397 (24-003) |

General equipment:

- Putty knife

- wooden block

- rolling jack

- Repair shop crane

| Name | Specification |

| Sealant for camshaft bearing caps | WSK-M2G348-A5 |

| sealant | WSK-M4G348-A5 |

| Sealant remover | WSK-M2G348-A4 |

| Engine oil | WSS-M2C912-A1 |

| Silicone grease for spark plug connector seals | A960-M1C171-AA |

Withdrawal

1. General instructions:

- The position of the engine mounts and engine roll limiters in the description corresponds to the view from the gearbox towards the engine.

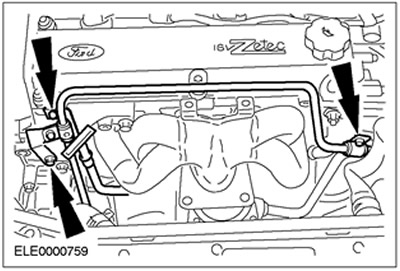

- If necessary, use special tool 303-397 to remove coolant and vent hoses.

- Due to the different variants of one vehicle model, some operating steps are not applicable to all vehicles. In this case, this is clearly stated in the text.

2. Standard preparatory activities:

- Note the radio key code.

- Check the preset radio stations.

CAUTION: Disconnect the ground wire from the battery.

- If necessary, cut the clamps and install new ones when installing.

3. Drain coolant. Refer to Section 303-03 for more information.

4. Remove the timing belt. For more information, refer to the Timing Belt chapter found in this section.

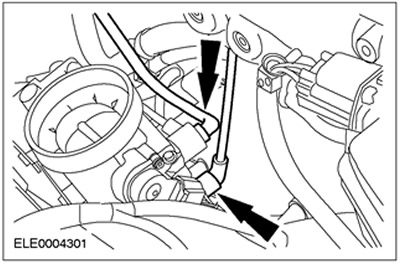

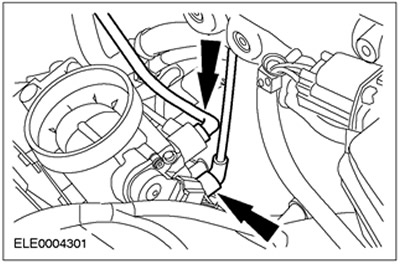

5. Disconnect the brake booster line and PCV hose from the intake manifold.

- Release the quick coupling and disconnect the vacuum brake booster line.

- Disconnect the crankcase ventilation hose.

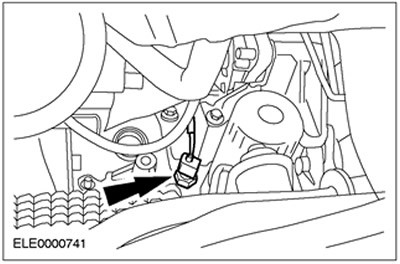

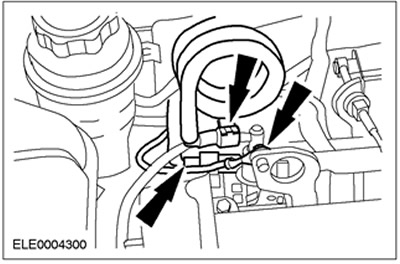

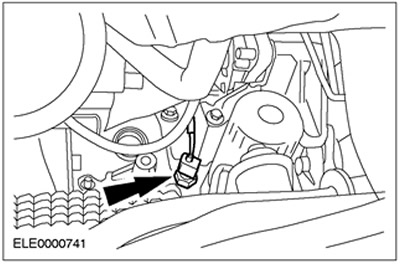

6. Disconnect the plug connector of the oil pressure switch.

7. Lower the car.

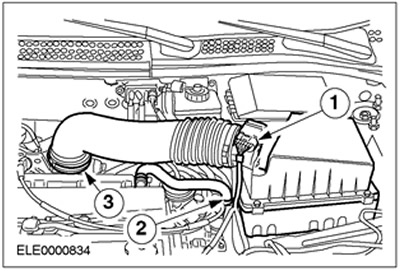

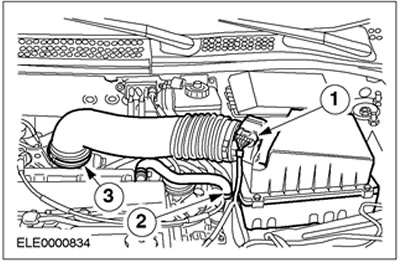

8. Remove the air filter housing.

- 1. Disconnect the plug connector of the mass air flow sensor (MAF).

- 2.Disconnect the PCV hose.

- 3.Disconnect the inlet hose.

- Remove the air filter housing from the rubber bushing.

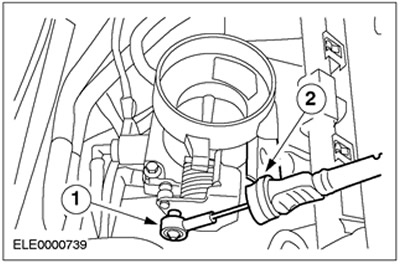

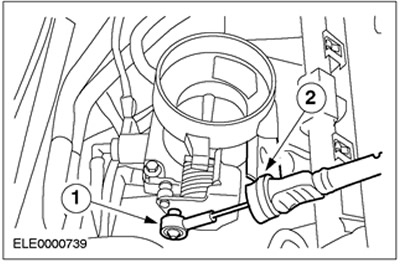

9. Disconnect the accelerator cable.

- 1.Unhook the rope.

- 2.Remove the plastic clip and set the accelerator cable aside.

10. Disconnect the low pressure hoses.

11. Disconnect the plug connector of the wiring harness and the plug connector of the temperature sensor of the cylinder head (CHT).

12. Relieve fuel pressure. Refer to Section 310-00 for more information.

13.

WARNING: Fuel leakage. Observe fuel handling precautions.

Disconnect the fuel lines. Disconnect the ground wire.

14. Remove the heat shield.

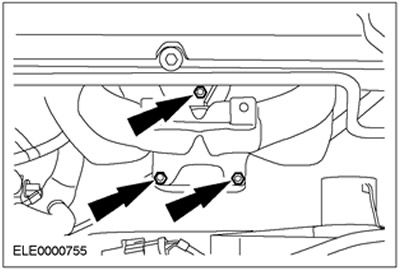

15. Disconnect the thermostat housing.

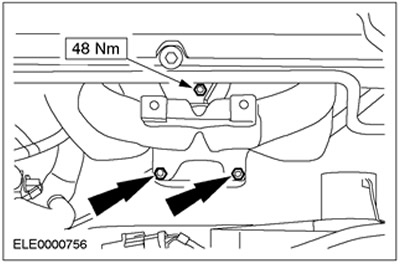

16. Disconnect the catalytic converter from the exhaust manifold.

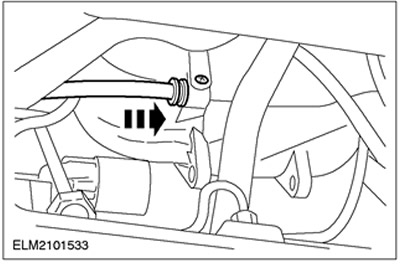

17. Disconnect the power steering line bracket and the oil dipstick tube.

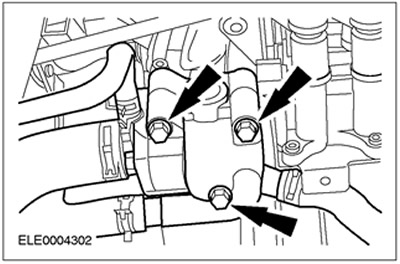

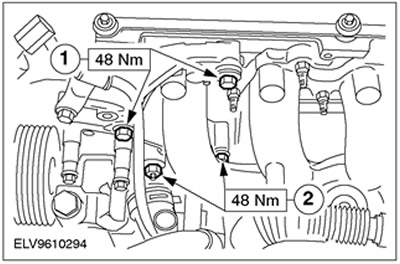

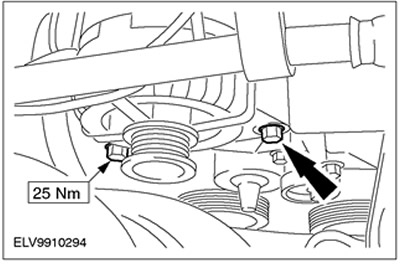

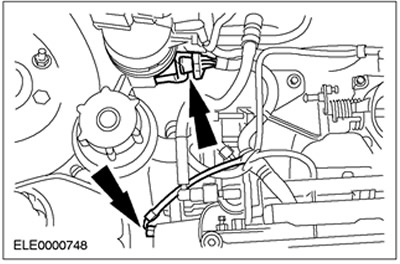

18. Remove the power steering pump bracket.

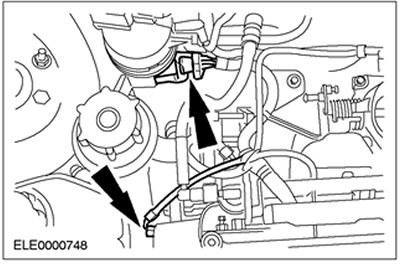

19. Disconnect the generator.

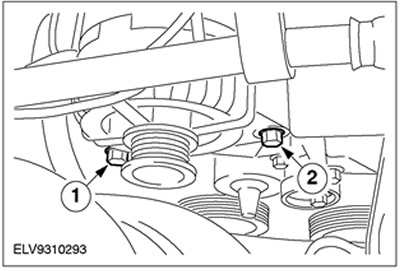

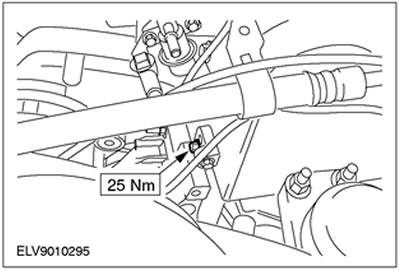

- 1. Remove the bolt.

- 2. Remove the bolt.

20. Turn out the top bolt from an arm of the generator.

21.

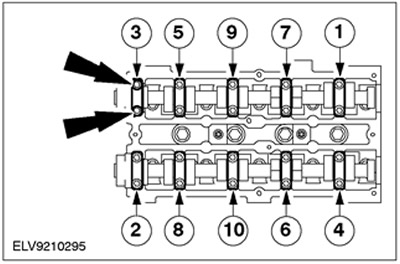

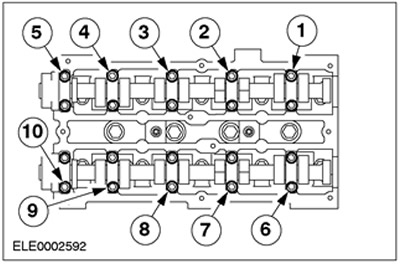

NOTE: Follow the release sequence.

Loosen the camshaft bearing cap bolts, working evenly, in several steps, turning two turns at a time.

- Remove oil seals.

- Remove camshafts.

- Remove the pushers and arrange them in order.

22.

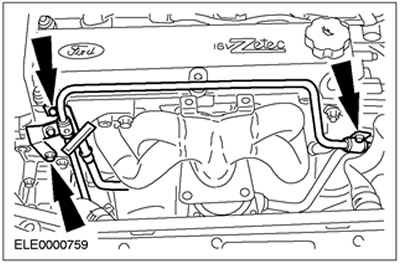

CAUTION: Mark the bolts to be reused by making one or two marks on them with a center punch. Bolts can be reused twice. If necessary, discard the bolts as they are no longer needed.

CAUTION: The cylinder head must be cooled to outside temperature.

NOTE: Follow the release sequence.

Turn out bolts of a head of cylinders.

23. Remove the cylinder head and set it aside on a clean surface.

Installation

1. General remarks. If necessary, use special tool 303-397 to remove coolant and vent hoses.

2. Preparatory operations:

CAUTION: Do not damage the cylinder liner. Remove carbon deposits from the top edge of the cylinder.

- Remove all traces of sealant using a sealant remover and putty knife.

- Thoroughly clean the threaded holes for the cylinder head bolts.

3. Check the cylinder head for deformation. Refer to Section 303-00 for more information.

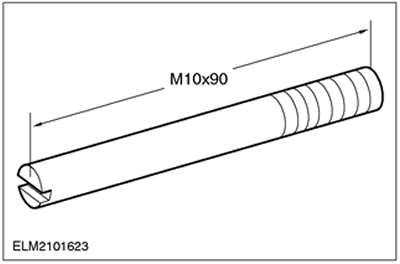

4. Make guide studs as shown.

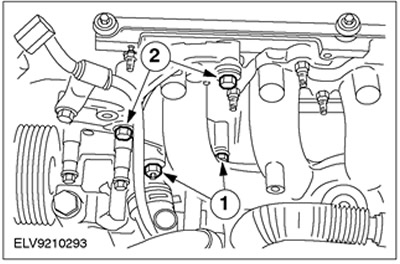

5.

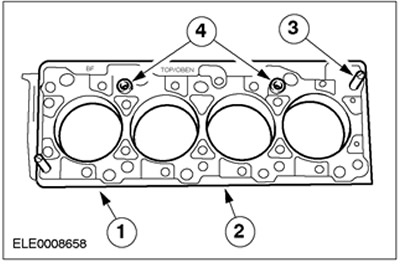

CAUTION: Cylinder head gasket selection depends on the cylinder block casting number.

Install a new cylinder head cover gasket to the cylinder block.

- 1. Cylinder block number

- 2.Install a new cylinder head gasket.

- 3.Install the prefabricated dowel pins.

- 4.Check that the guide pins are installed correctly.

6. Install the cylinder head. Align the position of the cylinder head on the cylinder block.

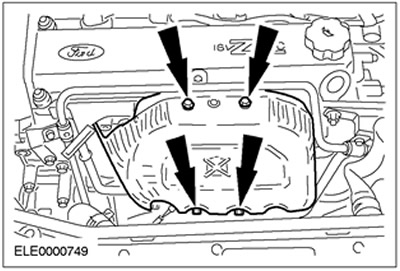

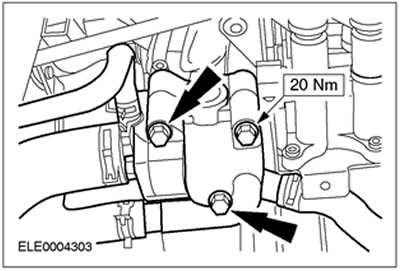

7.

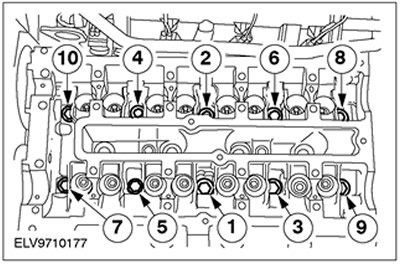

CAUTION: Do not overtighten the cylinder head bolts.

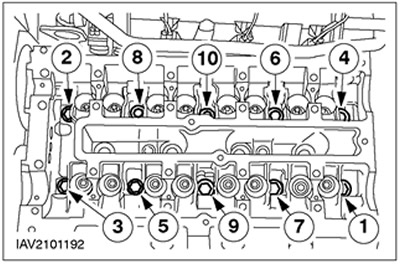

Tighten the cylinder head bolts using special tool 303-392, working in three stages in the sequence shown.

- Stage 1: 20 Nm

- Stage 2: 40 Nm

- Stage 3: 90 degrees

- Apply engine oil to the tappets and install them in the same order in which they were removed.

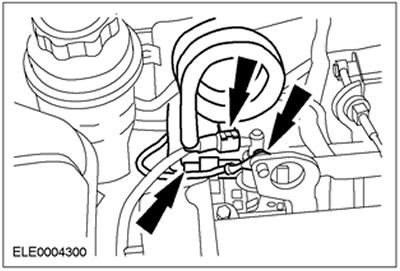

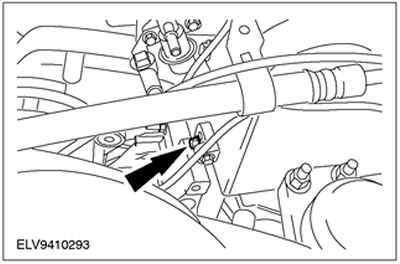

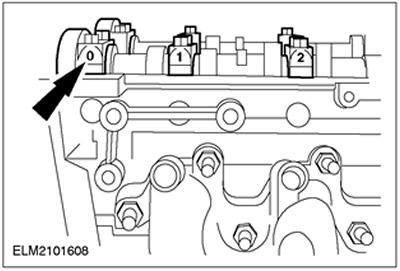

8. Apply sealant to the No. 0 and No. 5 camshaft bearing caps at the locations indicated.

9. Rotate the crankshaft to approximately 60 degrees before top dead center for cylinder #1.

10.

NOTE: Identification numbers are located on the outside of the camshaft bearing caps.

Reinstall the camshafts so that none of the cams is in the full lift position. Coat the camshafts and camshaft bearing caps with engine oil.

11.

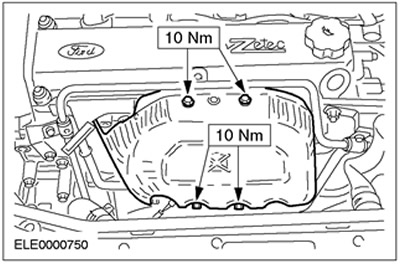

NOTE: Install the camshaft bearing cap bolts, working evenly, in several steps, in the sequence shown, half a turn at a time, and then tighten them, working in two steps.

Tighten the camshaft bearing cap bolts.

- Stage 1: 10 Nm

- Stage 2: 19 Nm

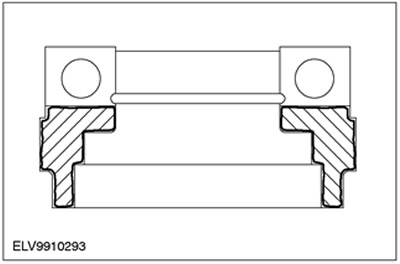

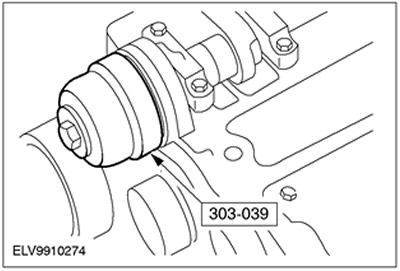

12. Install the camshaft oil seals.

- Coat the camshafts and oil seal lugs with engine oil.

- Install a new oil seal. Use the special tool, washer and M10x70 bolt.

NOTE: Do not overtighten the bolts. The camshaft pulleys must be able to rotate freely on the camshafts. Install pulleys.

13. Install the timing belt. For more information, refer to the Timing Belt chapter found in this section.

14. Lower the car.

15. Install the power steering pump bracket.

- 1.Install the top bolt.

- 2.Install the bottom studs.

- Tighten bolts and nuts.

16. Install the top bolt on the generator bracket.

17. Connect the generator.

18. Install the oil dipstick tube and power steering pipe bracket.

19. Connect the catalytic converter to the exhaust manifold.

20. Connect the thermostat housing. Use a new gasket.

21. Install the heat shield.

22. Connect fuel lines.

23. Connect the plug connector of the engine wiring harness and the plug connector of the SNT sensor.

24. Connect the accelerator cable.

- 1. Hook up the cable in the required position.

- 2.Install the plastic clip.

25. Connect vacuum hoses.

26. Install the air filter housing.

- Install the air filter housing into the rubber bushings.

- 1.Connect the plug connector of the mass air flow sensor (MAF sensor).

- 2. Connect the crankcase ventilation hose.

- 3.Connect the inlet hose.

27. Raise the vehicle. Refer to Section 100-02 for more information.

28. Connect the plug connector of the oil pressure switch.

29. Connect the brake booster hose and PCV hose to the intake manifold.

30. Standard final operations:

- Connect ground wire to battery.

- Refill coolant. Refer to Section 303-03 for more information.

- Close the expansion tank of the cooling system.

- Check fluid levels and correct if necessary.

- Check the wiring of vacuum hoses, cables and wires and secure them using clamps.

- Enter the radio key code.

- Reprogram preset radios.

- Set your clock.

- Carry out a road test to give PCM a chance to collect data.

- Check fluid levels again and correct if necessary.

NOTE: Engine oil temperature must be at least 80°C.

- Change engine oil and oil filter. For more information, please refer to the General Specifications chapter available in this section.

Visitor comments