Special tool

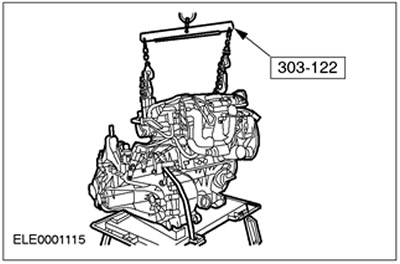

| Engine lift tool 303-122 (21068A) |

| Radiator hose clamp remover and installer 303-397 (24-003) |

General equipment:

- assembly table

- Fixing clamp

- Lift

- wooden blocks

| Name | Specification |

| Clamps | |

| High temperature grease | ESD-M1C220-A |

All cars

1. Replace locknuts and retaining ring. Use special tool 303-397 to install and remove coolant hoses and vent hoses, if necessary.

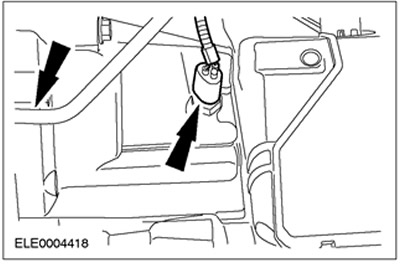

2. Preparatory operations:

- Using the fixing clamp for fastening, install the gearbox on the assembly stand.

- Mount the engine on a hoist, bring it into position in relation to the gearbox and support it using wooden blocks.

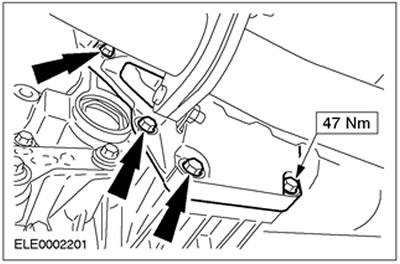

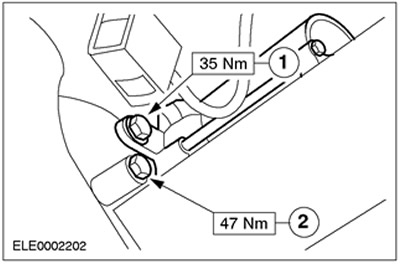

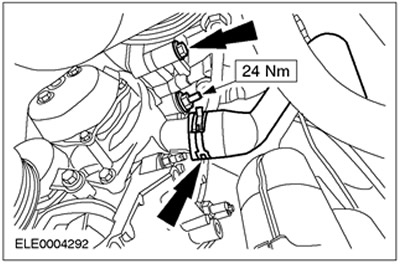

3. Tighten the flange bolts.

4. Tighten the flange bolts (continuation).

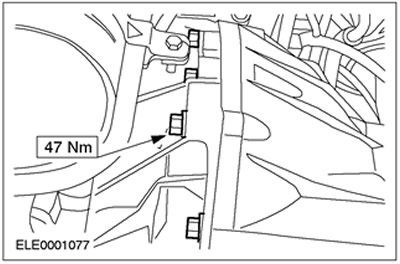

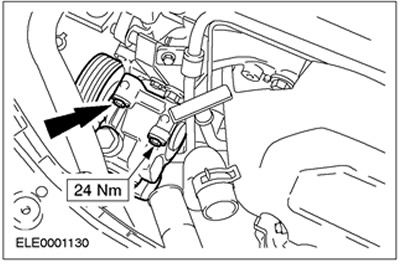

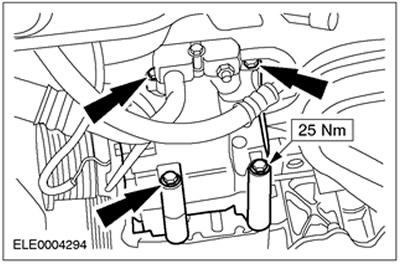

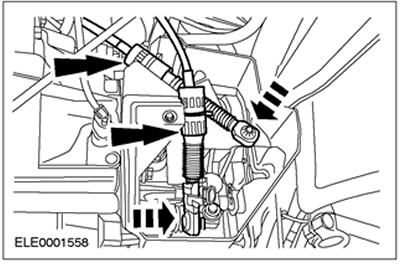

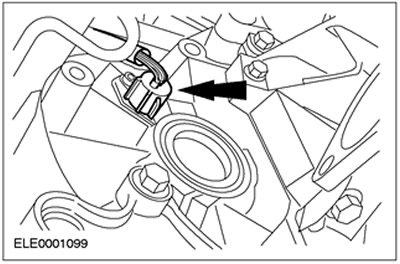

5. Install the starter and tighten the flange bolt.

- 1.Starter bolt

- 2.Flange bolt

6. Raise the vehicle. See Section 100-02 for more information.

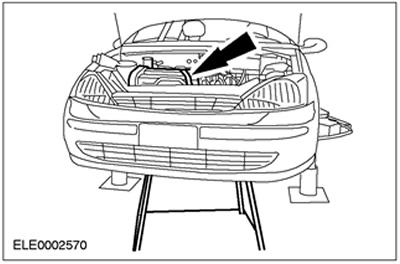

7. Install the engine assembly with the gearbox, fixed on the assembly stand, under the car. Lower the car carefully.

8.

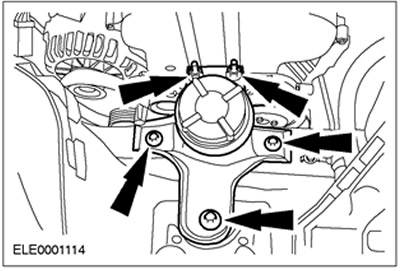

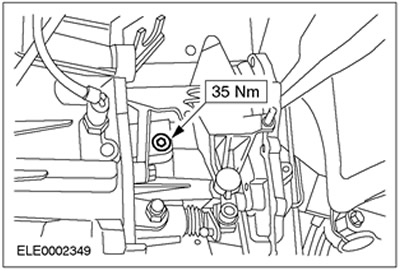

NOTE: Hand tighten and tighten bolts and nuts.

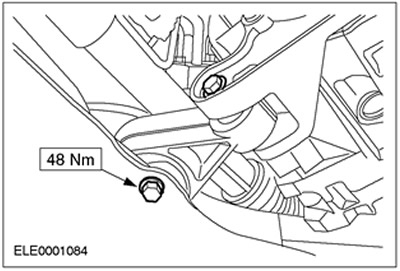

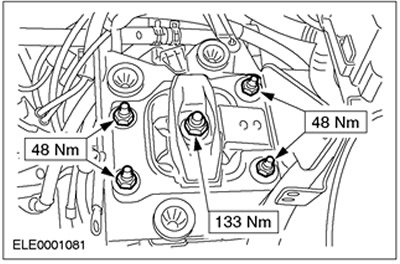

Install the front engine mount.

9.

NOTE: Hand tighten nuts.

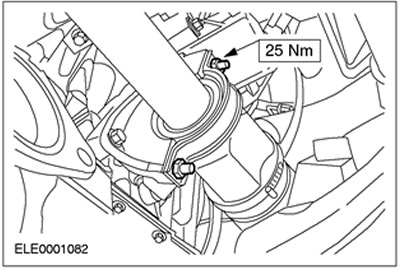

Install the rear engine mount.

10.

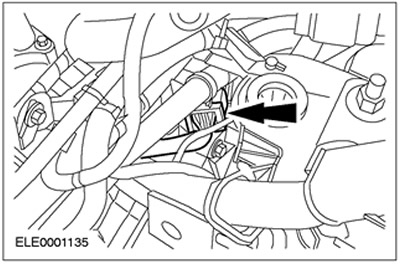

CAUTION: Brake fluid leakage. Observe the precautions for safe handling of brake fluid. See Section 206-00 for more information.

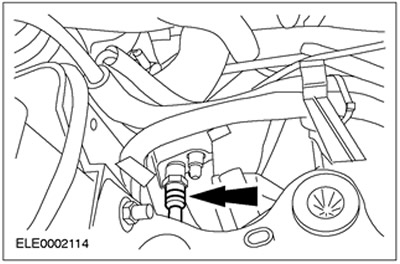

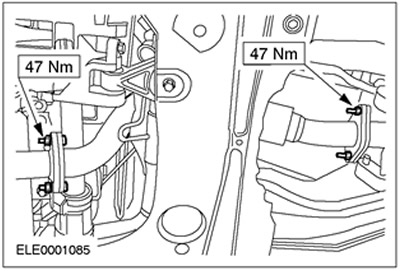

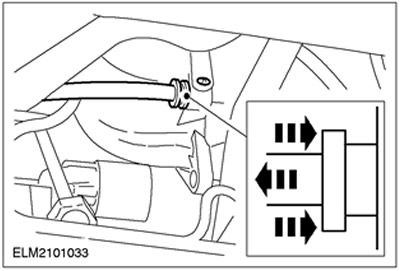

Connect the clutch slave cylinder high pressure pipe.

11. Remove a fixing collar from a transmission.

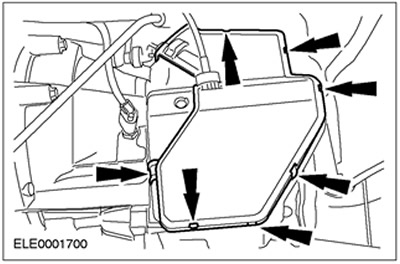

12. Raise the car. See Section 100-02 for more information. Remove the assembly stand.

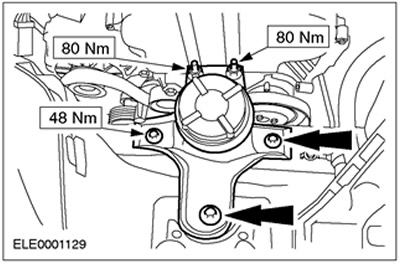

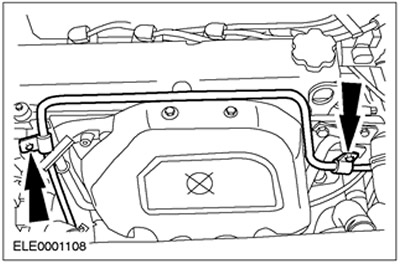

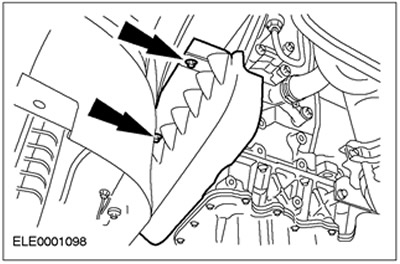

13. Install the engine roll limiter.

14.

CAUTION: The inner hinge must not be tilted more than 18 degrees and the outer hinge must not be tilted more than 45 degrees.

NOTE: Use new bolts and a new intermediate bearing cap.

Establish the right semiaxle of the forward leading bridge together with an intermediate shaft.

15.

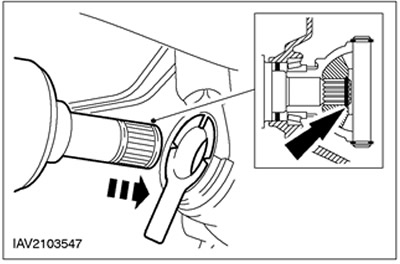

NOTE: Properly secure the circlip.

Insert the left axle shaft of the front drive axle together with a new circlip into the gearbox.

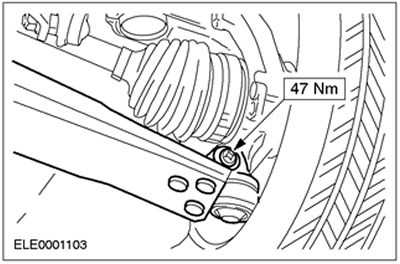

16. Connect both suspension arms (right side shown).

17. Install both front wheels. See Section 204-04 for more information.

18. Install flexible exhaust pipe.

19. Lower the car.

20. Tighten the nuts/bolts of the rear engine mount.

21. Tighten the front engine mount nuts.

22. Install the power steering pump and screw in the top bolts.

23. Connect an arm for the pipeline of a high pressure of the amplifier of a steering.

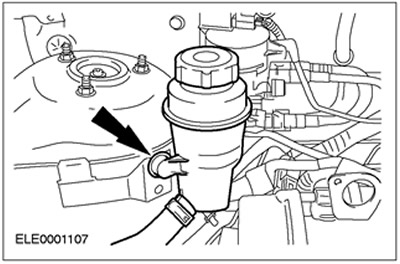

24. Connect the PAS tank.

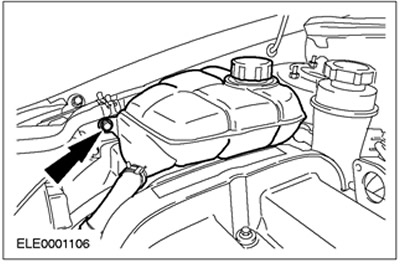

25. Install the expansion tank of the cooling system.

26. Raise the car. See Section 100-02 for more information.

27. Install the two lower power steering pump bolts and connect the coolant hose.

Vehicles with air conditioning

28. Install the air conditioning compressor.

All cars

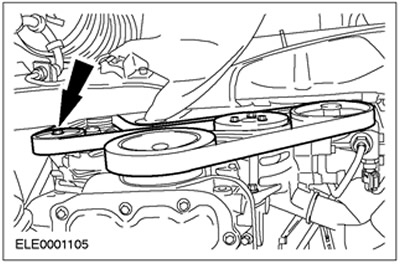

29. Put on and tension the drive belt (shown vehicle without air conditioning system). Turn the belt tensioner clockwise.

30. Install the drive belt cover.

31. Install the shift cable and gear selection cable. Install the shift cable and selector cable by turning the support ring located on the bracket clockwise.

32. Fill in the transmission fluid to the level (0-15) mm below the lower edge of the fluid level opening.

33. Establish a cover of cables of switching and a choice of transfers.

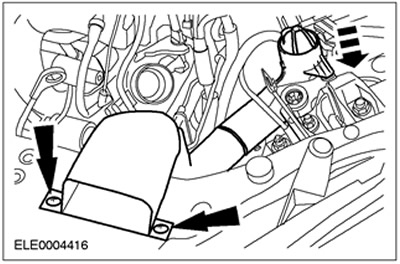

34. Install the air deflector and radiator fan. Align the position of the air baffle and fix it from above on both sides (left side shown).

35. Lower the car.

36. Connect coolant hoses.

37. Connect fuel lines. Connect wire "masses".

38. Connect a vacuum hose of the vacuum amplifier of brakes.

39. Connect vacuum hoses.

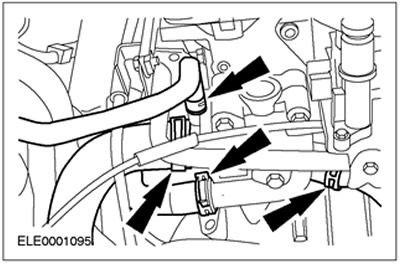

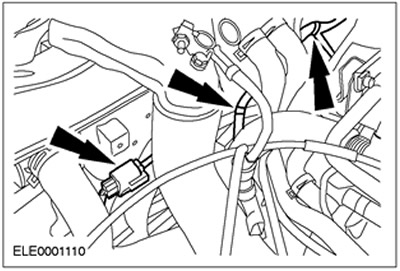

40. Dock the electrical connectors for the reversing light switch and the TFR sensor. Fix the engine wiring harness.

41. Dock the electrical connector of the VSS sensor.

42. Dock the electrical connector of the engine wiring harness.

43.

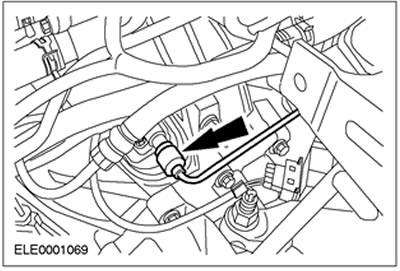

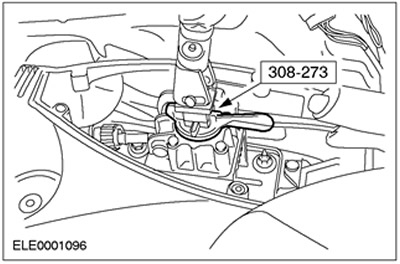

CAUTION: Brake fluid leakage. Follow the rules for safe handling of brake fluid. See Section 206-00 for more information.

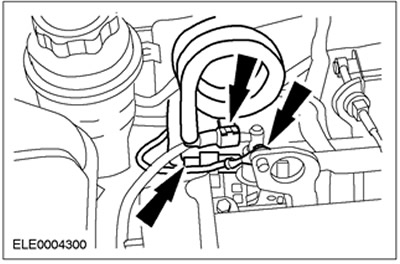

Connect the pressure line to the clutch slave cylinder. Install the spring clip.

44. Connect the radiator fan electrical connector. Install clamps.

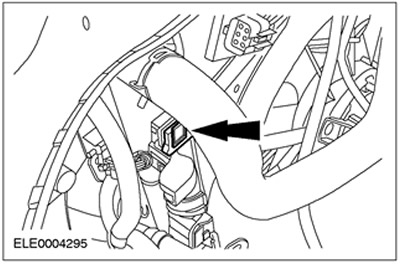

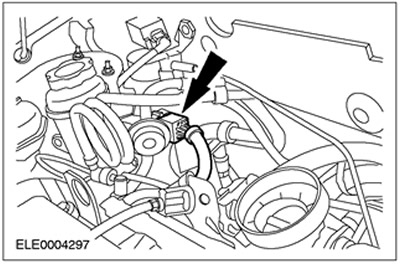

45. Connect the PCM electrical connector.

46. Dock the heated oxygen sensor connector (HO2S) and power steering pump pressure switch connector.

47. Connect the connectors of the EI coil and the RFI filter.

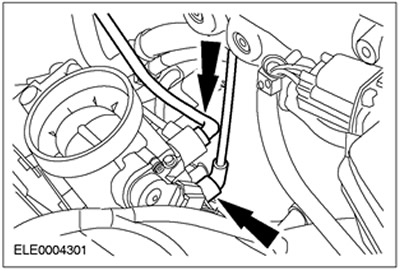

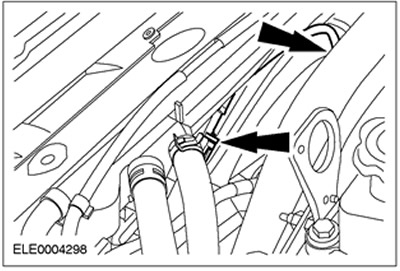

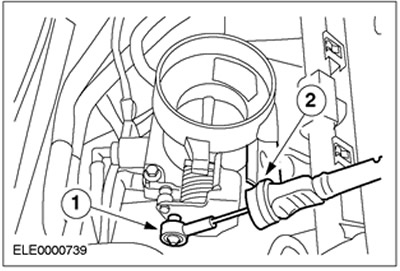

48. Install the accelerator cable.

- 1.Fix the accelerator cable.

- 2.Fix the plastic clip.

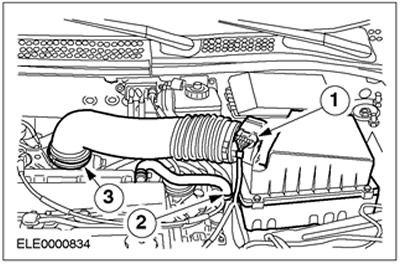

49. Install the inlet pipeline.

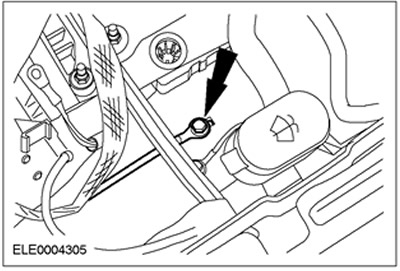

50. Connect the ground cable.

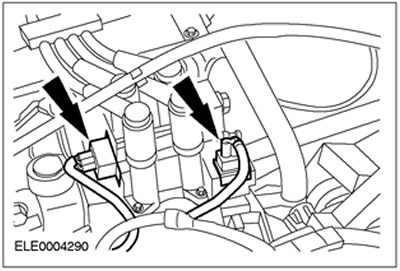

51. Install the air filter housing.

- Install the air filter housing onto the rubber bushing.

- 1.Connect the MAF sensor connector (MAF).

- 2. Connect the crankcase ventilation hose.

- 3.Connect the inlet hose.

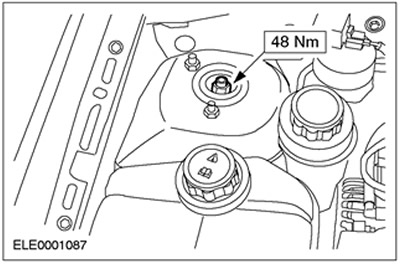

52.

NOTE: Lock against rotation with a hex wrench.

Tighten the suspension strut nuts on the right and left.

- Tighten by hand with a ring wrench.

- Use a torque wrench to tighten to the prescribed torque.

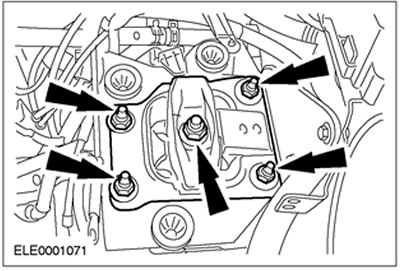

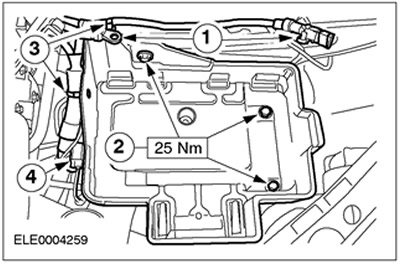

53. Install the battery tray.

- 1.Connect the wire "masses" and power cord.

- 2. Screw in the bolts.

- 3. Fix the wiring harness in the required position.

- 4.Place and secure the electrical connector.

54. Install the battery.

55. Disconnect the special tool. Fix covers.

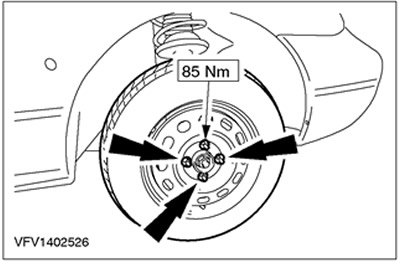

56. Tighten wheel nuts.

57. Standard final operations:

- Fill with coolant. See Section 303-03 for more information.

- Check the transmission fluid level and top up if necessary. See Section 308-03A / 308-03B / 308-03C for more information.

- Bleed the air from the hydraulic clutch. See Section 308-03A / 308-03B / 308-03C for more information.

- Enter the radio key code.

- Reprogram preset radios.

- Carry out a road test to allow the PCM to remember the data.

Visitor comments