Special tool

| Universal wrench for holding flanges 205-072 (15-030 A) |

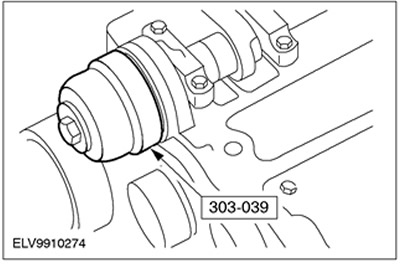

| Oil seal replacement tool 303-039 (21-009 B) |

| Oil seal replacement tool 303-291 (21-141) |

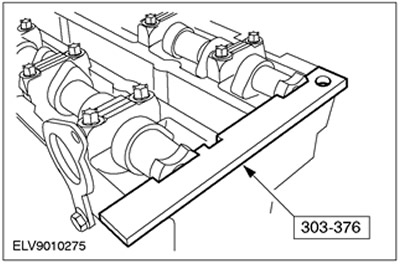

| Camshaft Top Dead Center Setting Tool 303-376 (21-162 B) |

| Flywheel locking tool 303-254 (21-135) |

| Clutch plate centering tool 308-204 (16-067) |

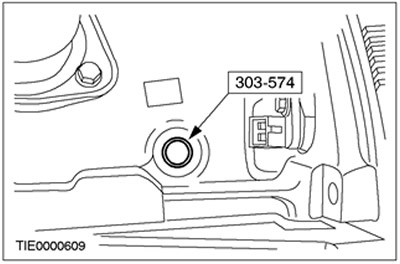

| Pin for setting the top dead center of the crankshaft 303-620 (21-163) |

| Socket wrench for cylinder head bolts 303-392 (21-167) |

General equipment:

- Piston ring compression tool.

- Scraper

- steel ruler

- Lift

| Name | Specification |

| High temperature grease | ESD-M1C220-A |

| Sealant remover | WSK-M2G348-A4 |

| Sealer for joints between cylinder block and oil pump/oil seal holder | WSK-M4G320-A |

| Sealant for camshaft bearing caps | WSK-M2G348-A5 |

| Oil sump sealant | WSS-M4G323-A7 |

| Engine oil | WSS-M2C912-A1 |

| Silicone grease for spark plug connector seals | A696-M1C171-AA |

1. Preparatory operations:

CAUTION: Do not damage the cylinder liner.

- Remove carbon deposits from the top edge of the cylinder.

- Using a scraper and sealant remover, clean all reusable parts and check for damage.

- Thoroughly clean all threaded holes.

2. Available sizes of main bearing shells.

NOTE: Main bearing shells are color coded.

- Size A: (2.145 - 2.152) mm (green color)

- Size B: (2.142 - 2.147) mm (Brown color)

- Size S: (2.135 - 2.142) mm (Brown color)

- Size D: (2.130 - 2.137) mm (Brown color)

3.

NOTE: Use main bearing shells of size "IN" or "WITH" (refer to the previous paragraph).

Measure the radial clearance of the crankshaft. See Section 303-00 for more information. Select the bearing shell, proceeding in accordance with the previous paragraph, in order to provide a clearance of (0.020 - 0.040) mm.

4. Measure the axial clearance of the crankshaft. See Section 303-00 for more information.

5. Measure the radial clearance of the camshaft. See Section 303-00 for more information.

6. Measure the axial clearance of the camshaft. See Section 303-00 for more information.

7. Measure the crankshaft. See Section 303-00 for more information.

8. Measure the camshaft. See Section 303-00 for more information.

9. Measure the cylinder diameter. See Section 303-00 for more information.

10. Measure the pistons. See Section 303-00 for more information.

11. Measure backlashes in joints of piston rings. See Section 303-00 for more information.

12. Measure the axial clearances of the piston rings. See Section 303-00 for more information.

13. Check cylinder head warp Refer to Section 303-00 for more information.

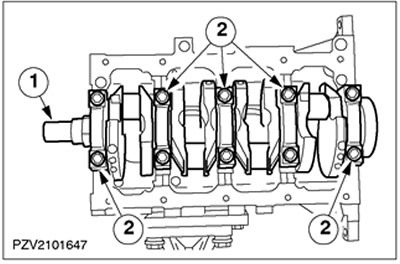

14. Install the crankshaft.

- • Install the main bearing shells in the cylinder block and coat them with engine oil.

- • Apply engine oil to the crankshaft main bearings.

- 1. Install the crankshaft in place.

NOTE: Do not tighten the main bearing cap bolts at this stage.

- 2. Connect the main bearing caps.

15.

NOTE: The connecting rods are numbered from the side where the timing belt is located. Valve recess in piston head facing exhaust side (only in 1.8L variant), the arrows point towards the timing belt.

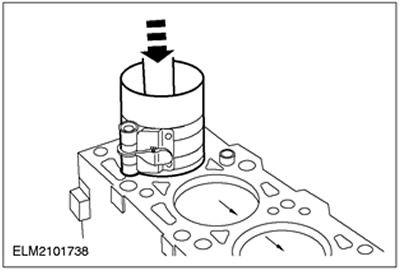

Install the pistons.

- Coat pistons and cylinder liners with engine oil.

- Distribute the joints of the piston rings and the elements of the oil scraper ring evenly around the circumference (after 120 degrees).

- Compress the piston rings. Use a piston ring compressor.

- Insert pistons into cylinders Nos. 1 and 4. Use a hammer handle to install. The bearing journals of the lower heads of the connecting rods of cylinders No. 1 and No. 4 must be in the bottom dead center position.

NOTE: Trademark designation "Ford" on the connecting rods faces in the direction of the timing belt.

- Insert clean, oil-free bearing shells into the connecting rod and into the bearing cap of the lower end of the connecting rod.

NOTE: Use new connecting rod bearing cap bolts.

NOTE: Do not tighten the connecting rod bearing cap bolts at this stage.

- Apply engine oil to the connecting rod journals and bearing shells of the lower connecting rod heads.

- Install the bearing caps.

- Rotate the crankshaft 180 degrees and insert pistons #2 and #3.

16.

NOTE: The crankshaft must turn freely. Check and adjust bearing clearances if necessary.

Tighten the main bearings and connecting rod bearings.

- 1.Tighten the main bearing cap bolts to 83 Nm.

- 2. Tighten the connecting rod bearing bolts in two steps.

- 1st stage: 15 Nm

- 2nd stage: 90 degrees

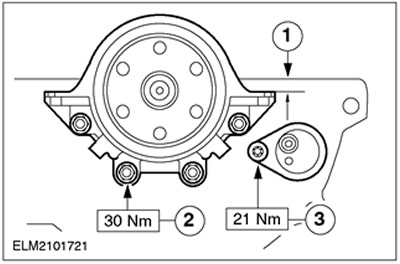

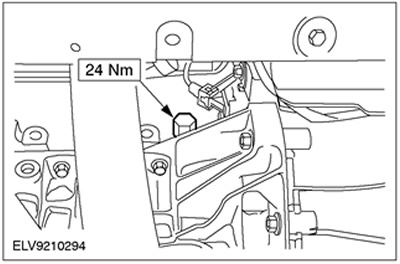

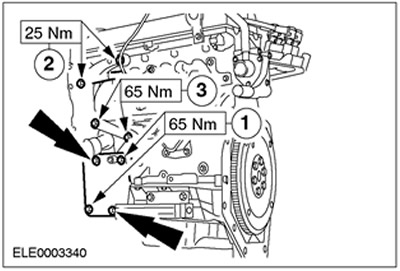

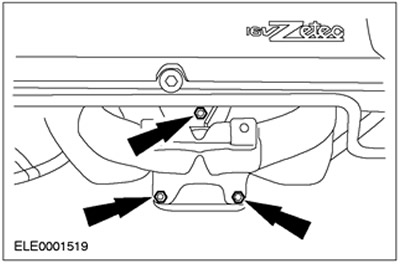

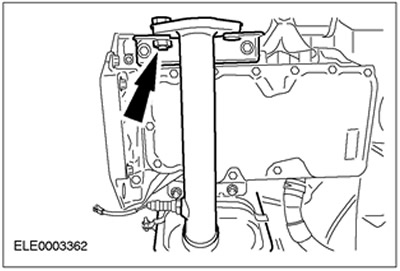

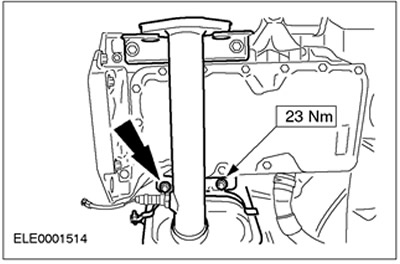

17. Install the rear oil seal holder and CKP sensor with bracket.

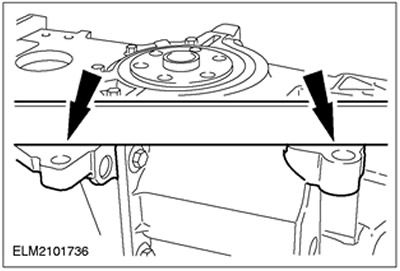

- Align the oil seal holder with the new oil seal and hand tighten the bolts.

- 1. Align the position of the oil seal holder so that its sealing surface is on the (0.3 - 0.8) mm below the cylinder block.

- 2.Tighten the bolts.

- 3. Connect the CKP sensor bracket.

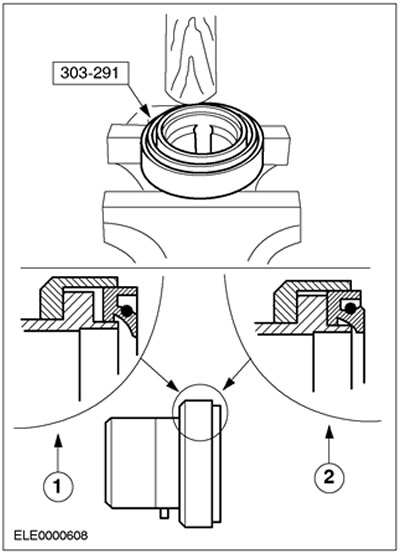

18.

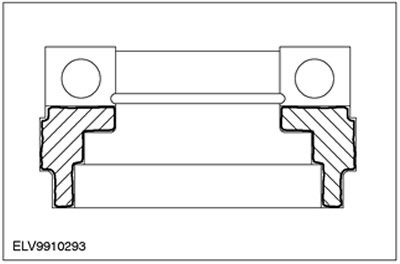

CAUTION: The oil seal must be inserted into the special tool 303-291 until it stops.

Insert a new crankshaft rear oil seal into the special tool.

- To ensure proper installation, hold the special tool in a vise and insert the oil seal using a hammer handle when installing.

- 1.Wrong installation

- 2.Proper installation

19.

NOTE: Use two flywheel bolts.

Insert the oil seal using the flywheel.

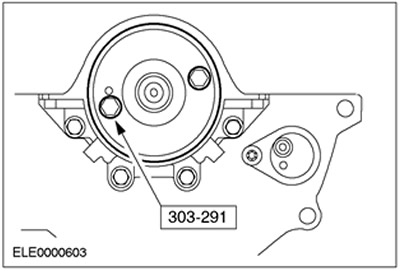

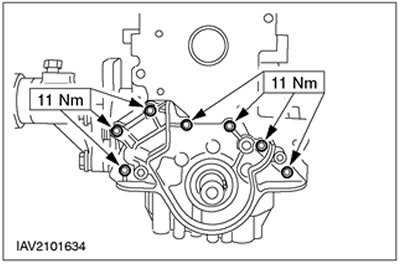

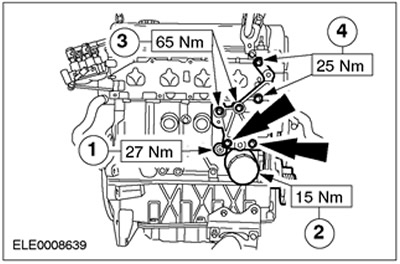

20. Check the position of the oil pump.

- Install the oil pump with a new gasket and hand tighten the bolts.

- Align the oil pump on both sides so that the mating surface is on (0.3 - 0.8) mm above the bottom edge of the cylinder block.

21. Install the oil pump with a new crankshaft front oil seal. Tighten the bolts and check the alignment as described in the previous paragraph. Correct if necessary.

22.

NOTE: The lower crankcase bolts must be tightened to the specified torque no later than 10 minutes after the sealant has been applied.

Align the position of the lower section of the crankcase.

- Apply sealant to the joints between the cylinder block and the oil pump/oil pump holder.

- Install the lower crankcase with a new gasket and hand tighten the bolts.

NOTE: If the allowable projections and/or clearances are exceeded, install the shims as described in the next paragraph.

- Align the position of the lower crankcase using a steel straightedge so that the cylinder block and lower crankcase are level or at least not more than the following offset:

- MTX 75 manual gearbox: 0.10 mm lug to 0.25 mm gap

- Automatic transmission: 0.00 to 0.25 mm gap.

23.

NOTE: From 01.99 only round spacers are used.

If necessary, install the distance washers of the lower section of the crankcase:

- at clearance (0.26-0.50) install 0.25mm spacers;

- at clearance (0.51-0.75) install 0.50mm spacers.

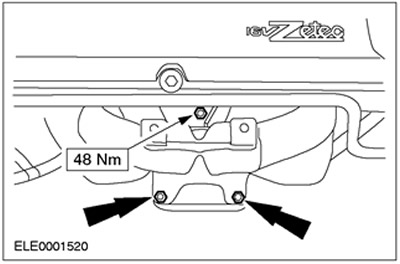

24. Connect the lower section of the crankcase and the inlet oil line along with a new gasket.

- 1. Tighten the bolts and check the alignment as described in the previous paragraph. Correct if necessary.

- 2. Oil intake pipe bolts

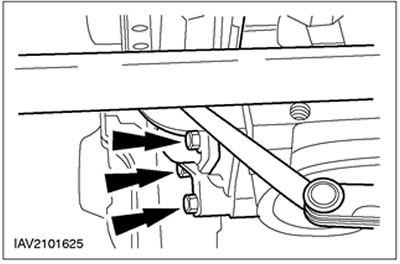

25.

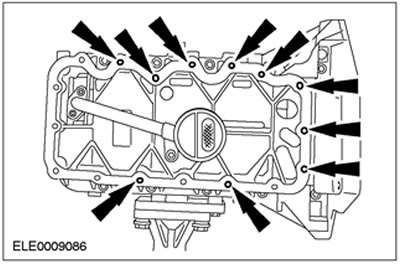

CAUTION: Use hairpins. If the sealant enters the blind holes, damage to the lower section of the crankcase may occur.

Screw ten studs (M6x20) into the blind holes shown.

26.

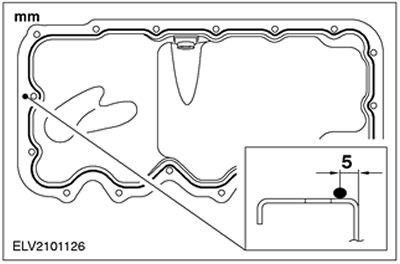

NOTE: Once the sump is in contact with the lower crankcase section, it must not be removed again.

NOTE: Fix the oil sump within 10 minutes after applying the sealant.

Apply sealant in a 3 mm wide strip to the mating surface of the oil pan.

27.

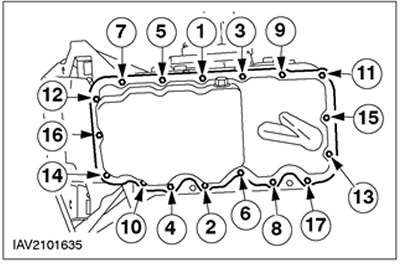

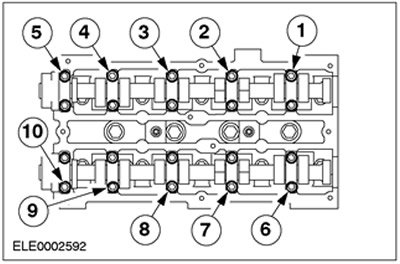

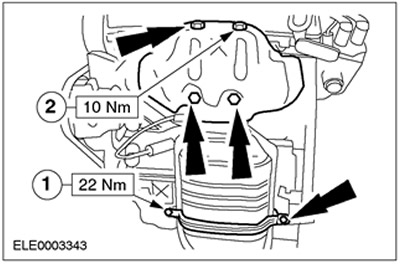

NOTE: Tightening sequence.

Install the oil sump and tighten the bolts, working in two stages.

- 1st stage: 6 Nm

- 2nd stage: 10 Nm

28.

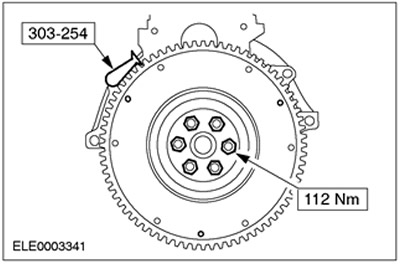

NOTE: Use new bolts.

NOTE: Remove any remaining thread locking compound from the threaded holes.

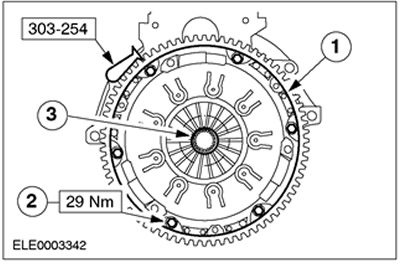

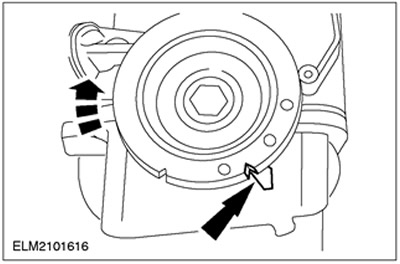

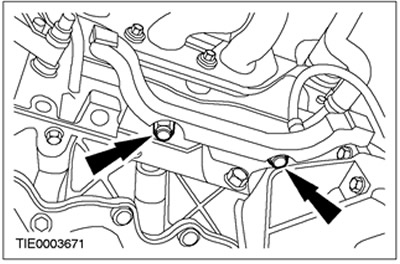

Install the flywheel. Install the special tool and tighten the bolts.

29.

NOTE: Apply a coat of high temperature grease. It should be so thin that when the clutch disc is pushed onto the input shaft of the gearbox, the lubricant is not squeezed out of the splines.

Apply high temperature grease evenly over the entire surface of the clutch disc splines.

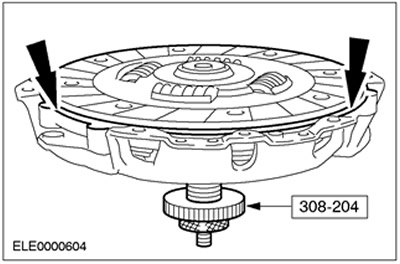

30. Center the clutch disc on the clutch pressure plate. Use a special tool.

31. Install the clutch.

- 1.Install the clutch pressure plate with the clutch disc centered on it.

- 2. Tighten the bolts in a criss-cross pattern, tightening one turn per step.

- 3.Check and, if necessary, correct the centering.

- Disconnect the special tool.

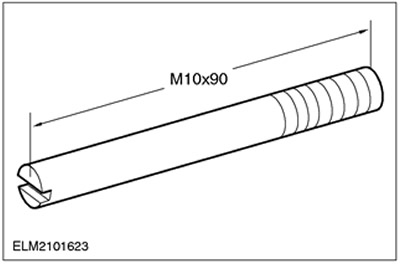

32. Make two guide pins as shown.

33.

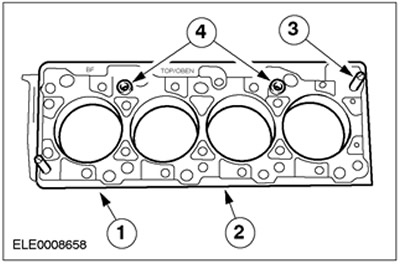

CAUTION: Cylinder head gasket selection depends on cylinder block casting number (1).

Install a new cylinder head gasket to the cylinder block.

- 1. Cylinder block numbers.

- 2.Install a new cylinder head gasket.

- 3. Screw in the guide pins made as described in the previous paragraph.

- 4. Check that the guide bushings are installed correctly.

34. Reinstall the cylinder head. Attach the cylinder head to the lifting eyes of the engine to the lift and move it to the required position.

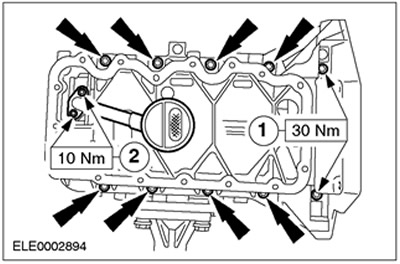

35.

CAUTION: Do not retighten the cylinder head bolts.

NOTE: Screw in clean (not oily) cylinder head bolts.

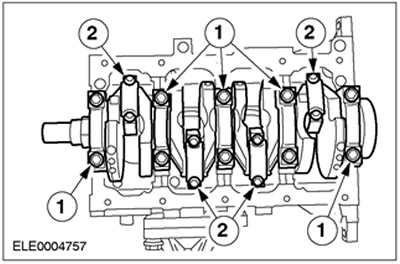

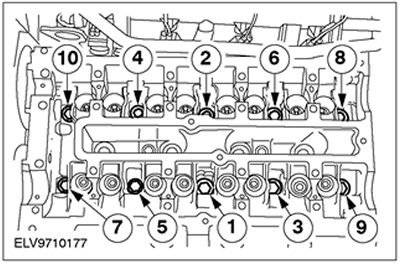

NOTE: Tighten the cylinder head bolts using special tool 303-392 in three steps in the sequence shown.

Install the cylinder head.

- 1st stage: 20 Nm

- 2nd stage: 40 Nm

- 3rd stage: 90 degrees

36. Apply engine oil to the valve lifters and reinstall them in the correct sequence.

37.

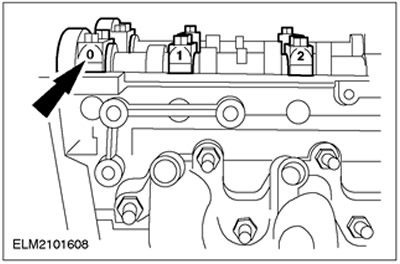

NOTE: Identification numbers are located on the outside of the camshaft bearing caps.

Apply sealant to the marked areas on camshaft bearing caps 0 and 5.

38. Rotate the crankshaft to approximately 60 degrees before top dead center.

39.

NOTE: Reinstall the camshafts so that none of the cams are in the full lift position.

Coat the camshafts and camshaft bearing caps with engine oil and install them in place.

40.

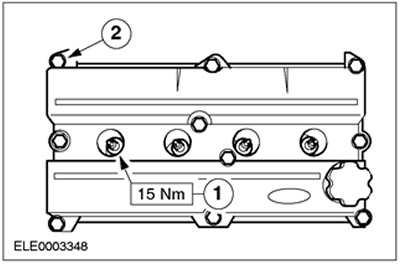

NOTE: Install the camshaft bearing cap bolts, working evenly, in several steps, in the sequence shown, half a turn per step, and then tighten the bolts, working in two steps.

Tighten the camshaft bearing cap bolts.

- 1st stage: 10 Nm

- 2nd stage: 19 Nm

41. Install the camshaft oil seals.

- Coat the camshafts and oil seal lugs with engine oil.

- Install a new oil seal. Use the special tool, washer and M10x70 bolt.

42. Rotate the crankshaft to top dead center for cylinder #1.

43.

NOTE: Cylinders #1 and #4 are at top dead center when the key is facing the piston.

Remove the plug and use the special tool to align the crankshaft to top dead center.

44. Rotate the camshafts to the ignition point for cylinder #1 and insert the special tool into the grooves on the ends of the camshafts.

45.

NOTE: Do not overtighten the bolts. The camshaft pulleys must turn freely on the camshafts.

Install the pulleys on the camshafts and screw in the bolts.

46. Insert a new gasket into the water pump.

- 1.Reinstall the gasket.

- 2.Fix the pad by bending the tabs.

CAUTION: Do not twist the timing belt (bend diameter must be at least 35 mm).

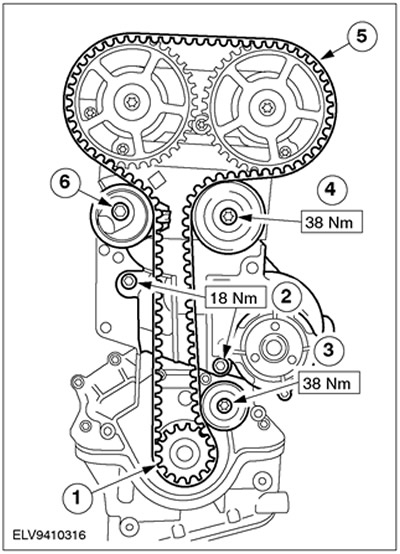

47.

CAUTION: Do not rotate the crankshaft. If necessary, check that the crankshaft rests against the special tool 303-620.

Put on a new timing belt.

- 1.Install the crankshaft pulley with thrust washer on the crankshaft.

- 2.Install the water pump.

- 3.Install the lower intermediate pulley.

- 4.Install the upper intermediate pulley.

- 5. Reinstall the timing belt, starting at the crankshaft pulley, working counterclockwise while keeping the belt tensioned continuously.

- 6.Install the belt tensioner and screw in the bolts 5 turns.

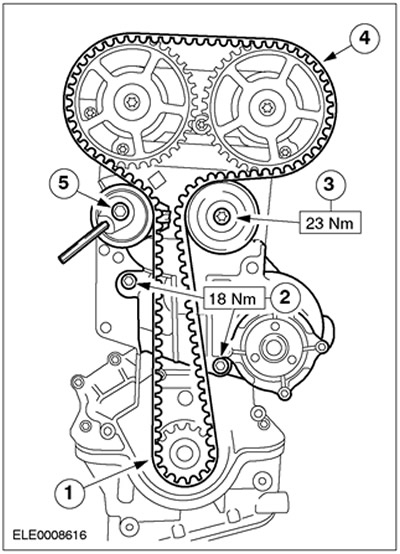

48.

CAUTION: Do not rotate the crankshaft. If necessary, check that the crankshaft rests against the special tool 303-620.

NOTE: Design shown without lower idler pulley (released starting around 01.99.).

NOTE: The tab on the timing belt tensioner must not catch on the metal cover.

Put on a new timing belt.

- 1.Install the crankshaft pulley with thrust washer on the crankshaft.

- 2.Install the water pump.

- 3.Install the intermediate pulley.

- 4. Reinstall the timing belt, starting at the crankshaft pulley, working counterclockwise while keeping the belt tensioned at all times.

- 5.Install the belt tensioner and screw in the bolts 5 turns.

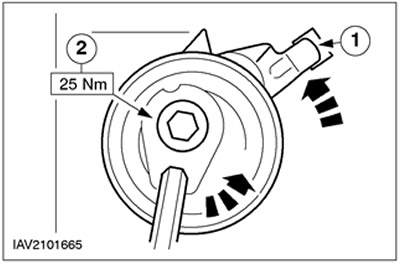

49.

CAUTION: Tension the timing belt tensioner only by turning it counterclockwise.

NOTE: If the belt tension is not adjusted correctly, it will result in incorrect valve timing.

Tension the timing belt.

- 1. Attach the belt tensioner to the metal cover.

- 2.Tighten the timing belt by turning the tensioner counterclockwise until the arrow and mark match, then tighten the bolt.

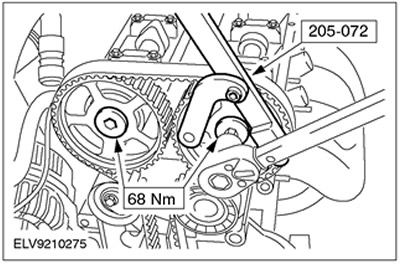

50.

CAUTION: Do not tighten the camshaft pulley bolts while holding the camshafts from turning with special tool 303-376. Use special tool 205-072 to prevent rotation.

NOTE: The crankshaft must be in the TDC position of cylinder #1.

Tighten the camshaft pulley bolts.

51. Unscrew and remove special tool 303-620.

52. Remove the special tool 303-376 from the camshafts.

53.

NOTE: Rotate the engine two revolutions in the direction of normal crankshaft rotation.

Check the valve timing by installing special tools and correct the alignment if necessary.

- Screw in the special tool 303-620 and make sure that the crankshaft rests against the special tool.

- Insert special tool 303-376 into the grooves on the ends of the camshafts. If necessary, loosen the pulleys and correct the alignment of the camshafts.

- Disconnect special tools.

54. Install the plug.

55.

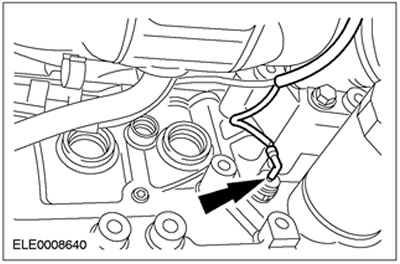

CAUTION: To avoid damage to the spark plug connector seal, use a blunt object to apply silicone grease (e.g. plastic clamp).

CAUTION: When mating the spark plug connector, keep it in line with the spark plugs.

NOTE: Coat the inside of the spark plug connector with silicone grease to a depth of (5-10) mm.

Install the cylinder head cover and spark plugs.

- 1. Screw in the spark plugs.

- 2. Tighten the cylinder head cover bolts in two steps. 1st stage: 2 Nm. 2nd stage: 7 Nm

- Match the spark plug connectors so that they snap into position.

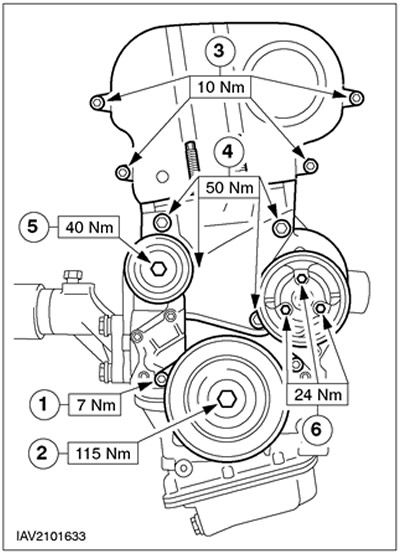

56. Install the timing belt covers and pulleys.

- 1.Bottom cover

- 2.Crankshaft pulley/damper

NOTE: Check top cover gasket installation and adjust gasket if necessary.

- 3.Top cover

- 4.Center cover/front engine mount bracket

- 5.Intermediate pulley drive belt

- 6.Water pump pulley

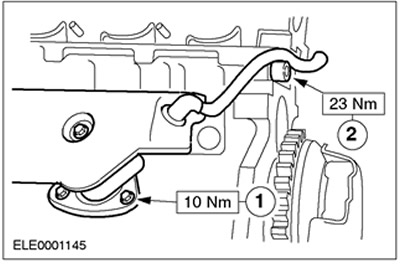

57. Connect the forced crankcase ventilation hose. Use a new seal.

- 1.Three bolts

- 2.One bolt

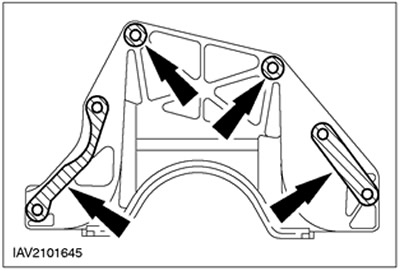

58. Connect the auxiliary elements located on the exhaust side.

- 1.Bracket for air conditioning compressor

- 2. Bracket for power steering pump mounted on the cylinder head

- 3. Bracket for power steering pump mounted on the cylinder block

59. Hook the hoist onto the engine lifting eyes and remove the engine from the assembly stand. Mount the engine on the assembly stand and leave it attached to the hoist.

60.

NOTE: Coat the oil filter seal with engine oil.

Connect the auxiliary elements located on the inlet side.

- 1. Oil pressure switch

- 2.Install a new oil filter.

- 3. Generator bracket fixed on the cylinder block

- 4. Generator bracket mounted on the cylinder head

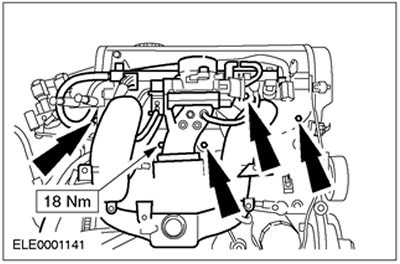

61. Install the intake manifold. Install seven bolts and two nuts.

62.

CAUTION: To avoid damage to the catalytic converter, always follow the correct sequence of steps when installing it.

Release the catalytic converter bracket just enough so that it can be moved freely.

63.

NOTE: Use a new gasket.

NOTE: Do not tighten nuts/bolts at this stage.

Position the catalytic converter on the exhaust manifold.

64. Using a nut and bolt, temporarily secure the catalytic converter to the bracket located at the rear.

65. Tighten the bolts securing the catalytic converter to the exhaust manifold.

66. Fix the catalytic converter.

- 1. Tighten the bolts on the catalytic converter mounting bracket.

- 2.Install the heat shield.

67. Connect an arm for fastening of catalytic converter.

- Tighten the bolts.

- Remove the temporary bolt from the rear catalytic converter mounting bracket.

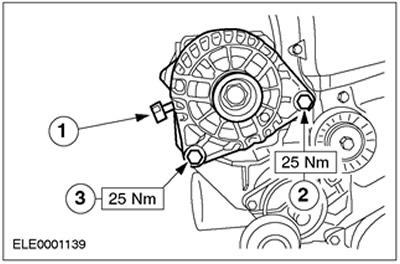

68. Install the generator.

- 1. Screw in and tighten the bolt.

- 2.Tighten the bolt.

- 3. Connect the positive wire.

69. Dock the electrical connector of the oil pressure switch.

Visitor comments