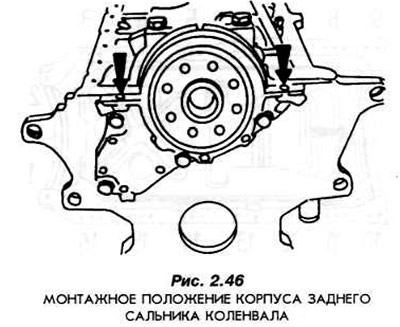

Install the new oil seal as follows:

- Lubricate the crankshaft journal and seal lips liberally.

- install the gland on the guide 21-011 E.

- install guide 21-011 E so that its two holes align with the two threaded holes in the crankshaft flange.

- lightly hammer the guide with the stuffing box until. until it is possible to screw the guide to the crankshaft flange with two M10x1x38 bolts.

- tighten the bolts in such a way that the guide would fit snugly on the shaft.

- remove the guide.

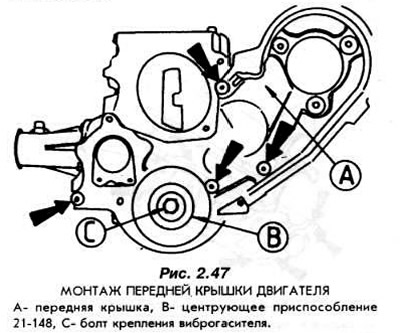

Install the front cover using tool 21-148 to center it (pic. 2.47).

Install a new oil seal using tool 21-148. The gland must be inserted into the socket until it stops.

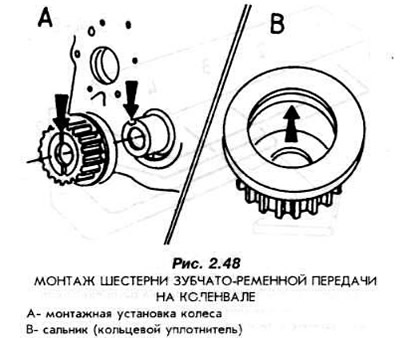

Install the gear on the front crankshaft journal. The protrusion on the crankshaft journal must be in the gear groove (pic. 2.48).

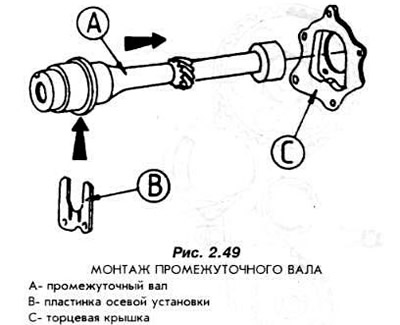

Install the intermediate shaft with the axial washer.

The recess in the washer must be visible from the front of the engine (pic. 2.49).

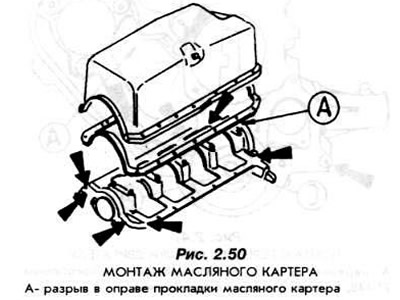

Install oil sump with new gasket (pic. 2.50).

Pay attention to the correct installation of the gasket. First tighten the bolts on the corners of the oil sump firmly by hand (1, 2, 9, 10 fig. 2.51). Then tighten bolts 3-8 and 11-16 as well as corner bolts.

Install the water pump.

Install a new intermediate shaft seal housing. The seal is one piece with the housing and cannot be replaced. Install the housing together with the plastic gland in it (sealing ring).

Screw the oil pump with a new gasket to the engine housing. Before installing, fill the pump with about 10 cm3 of engine oil.

Screw on the oil filter by hand along with a well lubricated gasket.

Measure the protrusion of the pistons with an indicator.

The protrusion of each piston must be measured. when it is at TDC. For measurement, the indicator must be installed on the top plate of the motor housing, as shown in fig. 2.52.

The protrusion of each piston must be measured at two points located opposite each other on the axis of the piston pin. The measuring tip of the indicator should be attached at a distance of 5 mm from the edge of the piston bottom.

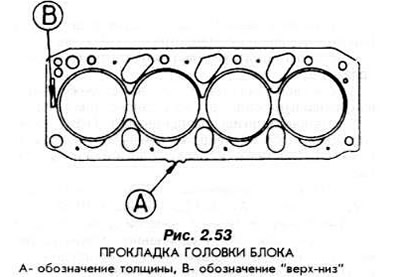

Select a new head gasket according to the information given in section 1.1 (pic. 2.53). Degrease the seating surface of the cooking block (head gasket contact surface).

Set the crankshaft to a position where the pistons of the first and fourth cylinders will be at TDC.

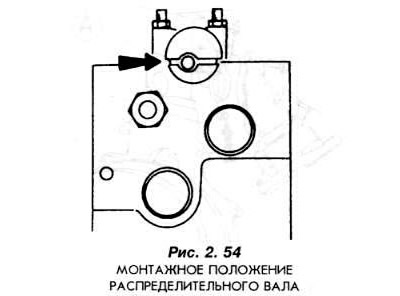

Install the camshaft according to fig. 2.54.

Lay the head gasket on the plane of the engine housing.

Put the head of the block and screw it with new bolts (pic. 2.55).

The bolts securing the block head are tightened in the following way:

- Stage I: 20-30 Nm.

- Stage II: 76-92 Nm.

- wait at least 2 minutes.

- Stage III: turn the bolts 90°.

It is not necessary to additionally tighten the bolts securing the block head after a certain period of operation has elapsed.

Screw in the spark plugs.

Install a bunch of electrical wires.

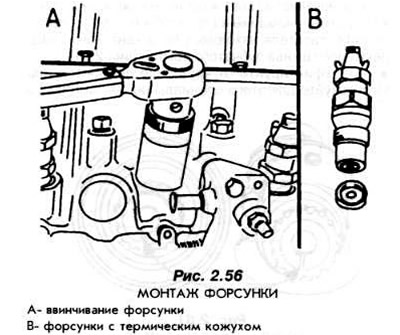

Screw in the nozzles with the GV-2304 wrench (pic. 2.56). Use new sprayer housings.

Screw the thermostat housing to the block head.

Connect flexible hose to water pump and thermostat.

Install the coolant flow splitter.

Note: The flexible coolant hose is connected to the pump in such a way that the white mark on the hose matches the boss on the pump fitting.

Install the alternator bracket.

Attach the generator clamp.

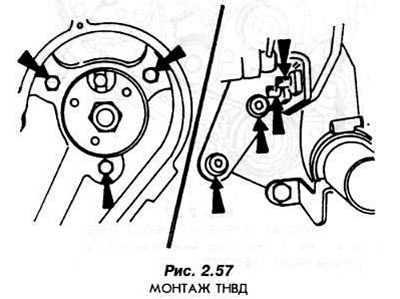

Screw the injection pump to the front wall of the engine housing (pic. 2.57).

Connect the high pressure fuel pipes connecting the injection pump to the injectors.

Install overflow fuel lines to drain excess fuel from the injectors.

Install according to fig. 2.58 vacuum pump:

- screw in the bottom bolt

- put a pump on it.

- screw in the top bolt.

- tighten both bolts evenly.

Connect the excess fuel overflow pipe.

Screw on both lower tin covers covering the toothed belt.

Install: a belt pulley driving a toothed belt mounted on the crankshaft; drive belt pulley mounted on the camshaft; as well as a toothed belt (pic. 2.59):

- install the gear on the camshaft journal,

- install the belt pulley driving the injection pump (find elongated holes on this wheel),

- set the belt tensioner to the initial tension,

- install the belt pulley on the intermediate shaft, correctly seating it on the locating pin,

- install the camshaft pulleys and injection pump in such a way that their holes or selections coincide with the holes in the block head or in the pump housing,

- insert setting rod 23-019 (camshaft and CAV pump) or 23-029 (BOSCH pump).

Note: If a CAV pump is installed in the fuel supply system, a new 6 mm diameter drill with a cylindrical shaft must be inserted into the elongated hole of the belt pulley.

Screw in the locating pin 21-104, which serves to designate the TDC. The pin must be screwed in until it stops and the crankshaft must touch it.

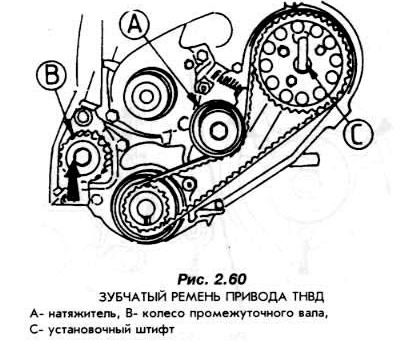

Install the new injection pump timing belt in such a way that the tension side of the belt is tensioned (pic. 2.60).

Unscrew the bolt holding the toothed belt tensioner half a turn. Tensioner "rebound" toward the toothed belt and tension it.

Note: When installing the toothed belt, pay attention to the direction of movement of the gear.

Screw in the TDC setting pin. Screw on the vibration damper using new bolts.

Note: When installing the belt pulley, make sure that the projection on the hub of the vibration damper is in the groove of the hub of the toothed belt pulley (pic. 2.61).

Secure the vibration damper against rotation. Use the special device 15-030 A for this.

Screw in the TDC locating pin again and fix the crankshaft in this position (TDC).

Install a new camshaft timing belt. The pulling side of the belt must be tight.

Loosen the fastening of the toothed belt tensioner, the tensioner will move towards the belt and tension it.

Then reattach the tensioner.

Remove all dowel pins. Rotate the crankshaft two turns in the same direction as when the engine is running. The elongated hole in the injection pump belt pulley must be installed in a position corresponding to "12 o'clock". Then slide it into position "11 o'clock".

In this position, screw in the TDC locating pin.

Carefully turn the crankshaft in the direction of rotation while the engine is running and bring it to the correct position relative to the dowel pin at TDC (pic. 2.43).

Place the dowel pins in the camshaft pulley and in the injection pump pulley. If a CAV injection pump is installed in the car, a drill shaft with a diameter of 6 mm must be used.

Loosen the bolts holding the belt pulleys half a turn and tighten both belts from the opposite side of the tensioner. Loosen the pressure on the straps. Retighten all bolts (pic. 2.62). Remove all dowel pins.

Unscrew the TDC locating pin from the housing.

Install the upper and lower camshaft drive belt covers.

Pay attention to the good fit of the nut securing the water pump. If necessary, use a sealant to seal it "Loctite-242").

Install and tension the alternator drive V-belt.

Install the generator cover.

Screw the flywheel with new bolts.

Adjust valve clearances as described in section 2.4 "Block head".

Install the block head cover.

Install intake and exhaust manifolds (pic. 2.63).

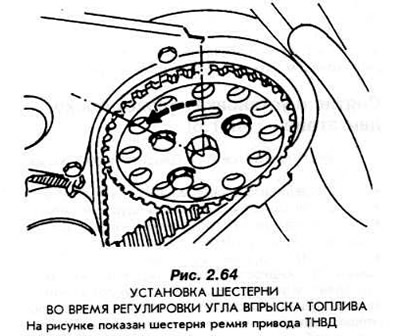

Set the start of fuel injection in the injection pump.

Rotate the crankshaft to the position shown in fig. 2.64.

Screw the TDC locating pin into the engine housing and turn the crankshaft towards that pin. Turn the shaft in the direction corresponding to the direction of its rotation while the engine is running.

Insert the dowel pin 23-029 or 23-019 through the hole in the injection pump drive belt pulley and through the hole in the front plate of the engine housing into the hole in the pump drive connection flange. The pin must fit freely into the holes. It should also be possible to insert it in depth to the end of its length.

If this cannot be done, loosen the belt pulley mounting bolts and turn the injection pump so that the dowel pin can be inserted into the holes without any difficulty. After completing the adjustment, tighten the bolts securing the injection pump drive gear strongly.

Visitor comments