Drain the engine oil.

Unscrew the oil filter.

Remove high voltage wires.

Unscrew the spark plugs.

Remove the filler neck.

Disconnect the pipes of the fuel supply system. as well as discharge tubes.

Remove the axle with valve levers and remove the push rods.

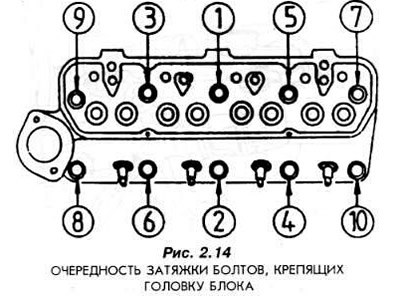

Unscrew bolts of fastening of a head of the block in sequence return, rather than it is shown in fig. 2.14. Unscrewing is carried out in several stages.

Remove the block head. If necessary, loosen it with light blows with a plastic hammer. Under no circumstances should any tools be inserted between the head of the block and the engine block.

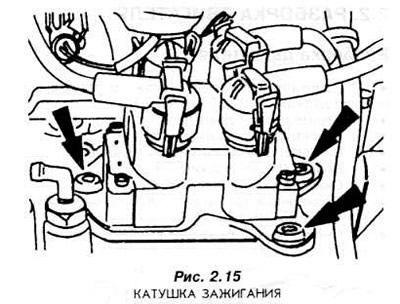

Unscrew the DIS ignition coil from the block (pic. 2.15).

Remove the fuel pump if it is attached to the engine.

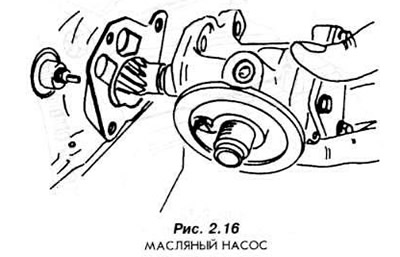

Remove the oil pump from the engine block (pic. 2.16).

Remove the water pump pulley.

Remove the water pump.

Remove the water pump drive pulley from the crankshaft.

Remove the oil sump from below, after unscrewing the fixing bolts.

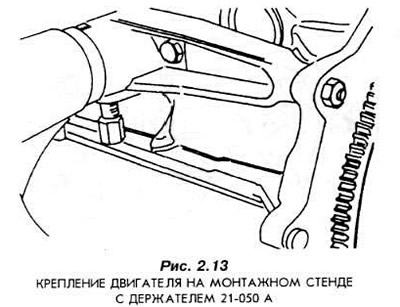

Rotate the motor on the mounting stand by 180°.

Remove the camshaft drive chain cover.

Remove the oil deflector from the crankshaft. Note its mounting position.

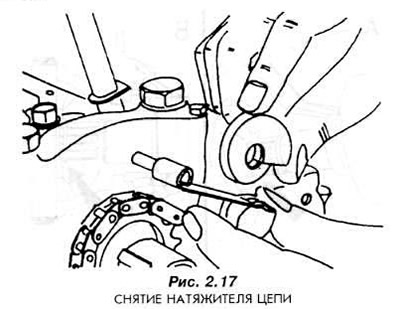

Remove the tensioner arm from the pin on the first crankshaft bearing cap. Remove chain tensioner (pic. 2.17).

Unlock the two bolts securing the cogwheel to the camshaft. Unscrew these bolts.

Remove the gear wheel along with the chain.

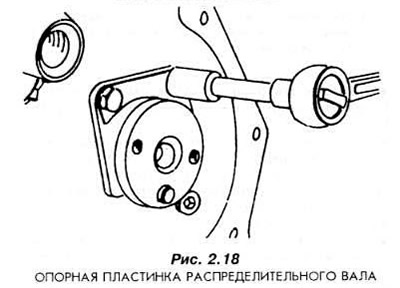

Unscrew the bolt securing the camshaft base plate (pic. 2.18).

Carefully pull the camshaft out of the engine housing.

Remove pushrods from engine housing. Store them in such a way that during assembly they are installed in the same holes from which they were removed. In no case do not confuse the installation locations of the pushers!

Remove pulley from crankshaft.

Install the pistons at approximately half the length of the cylinders and clean the edges of the cylinders from the remnants of burnt oil and deposits formed there. When doing this, be very careful not to damage the surfaces of the cylinders.

Loosen the connecting rod bolts and remove the connecting rod caps.

Pull up the pistons with connecting rods.

Remove the liners glued to the crankshaft journals. Without confusing them. fit into the respective connecting rods along with the appropriate caps and bolts.

Remove the bolts securing the clutch cover to the flywheel in several steps.

Remove flywheel.

Remove the engine speed sensor (pic. 2.19).

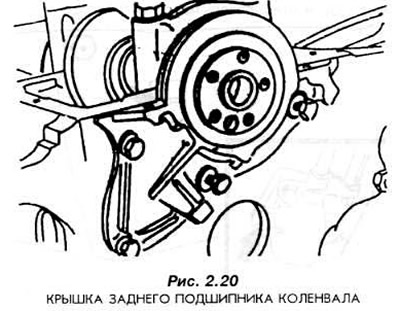

Unscrew the bolts securing the crankshaft rear bearing cover (pic. 2.20).

Remove the crankshaft main bearing caps.

Remove the crankshaft from the engine housing. Remove adhesive pads.

All parts, except for liners, degrease and clean. The bushings should be used to evaluate the serviceability of the bearings during engine assembly. Therefore, they must be kept intact.

Visitor comments