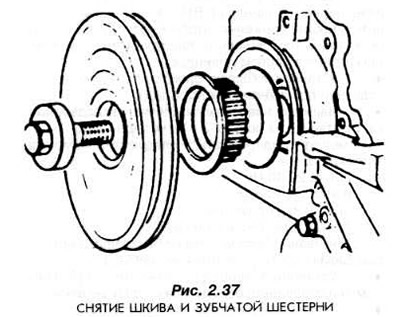

Lubricate the crankshaft journals and fasten the gears and wedges to it with a central bolt (see 2.37).

Install the water pump with a new gasket.

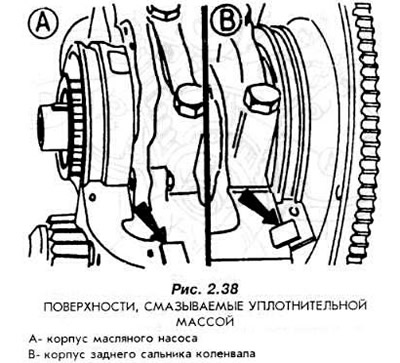

Lubricate the seating surface of the oil sump flange with sealing compound within the boundaries of the shockproof casing (pic. 2.38).

Place a new rubber gasket in the groove of the seal housing and fit the oil pump housing. To facilitate installation, screw ten M6 studs into the threaded holes.

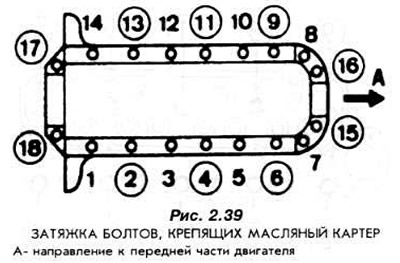

Install the oil sump and tighten the fixing bolts tightly.

Follow that. so that the pins centering the oil sump fall into the corresponding holes in the gasket.

Tighten the bolts in the correct order (pic. 2.39). reaching the tightening torque specified in section 1.1.

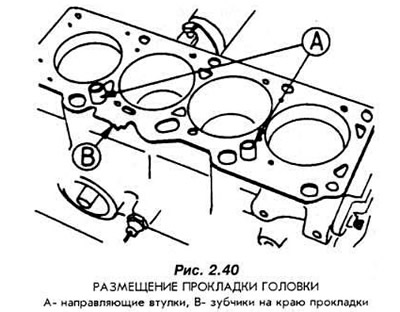

Install bushings in the engine housing centering the head gasket.

Degrease the seating surface of the block head and the upper plane of the engine housing. Use gasoline for this purpose.

Install a new head gasket (pic. 2.40).

Head gaskets have the following designations:

- two cloves (B, fig. 2.40) on the edge indicate the gasket for the 1.4i engine.

- the four teeth indicate the gasket for the 1.6i engine.

Before mounting the block head, set the piston of the first cylinder to TDC. Install the camshaft in such a position that the valves in the fourth cylinder are in the divergence position (ignition in the first cylinder).

Install the block head with a grease-free seating surface to the gasket.

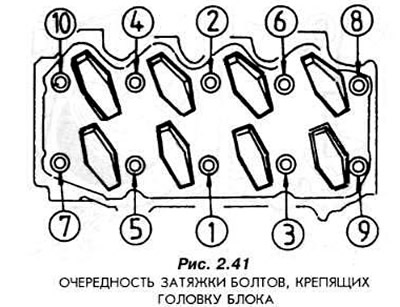

Screw in new bolts securing the block head. and tighten them according to fig. 2.41 in four steps.

The following bolt tightening torques must be adhered to:

- Stage I: 20-40 Nm

- Stage II: 40-60 Nm

- Stage III: rotate 90°

- Stage IV: rotate another 90°

Tightening the block head bolts after a while of engine operation is not required.

Loosely install the toothed belt tensioner and move it as far to the left as possible.

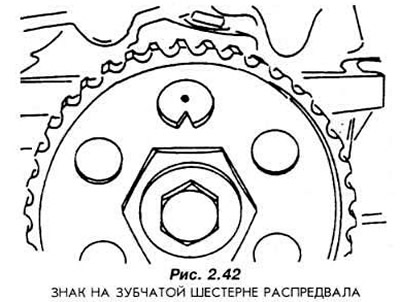

Install the camshaft according to fig. 2.42.

Rotate the crankshaft so that the marks match. as shown in fig. 2.43.

Install the toothed belt so that its left side is tensed.

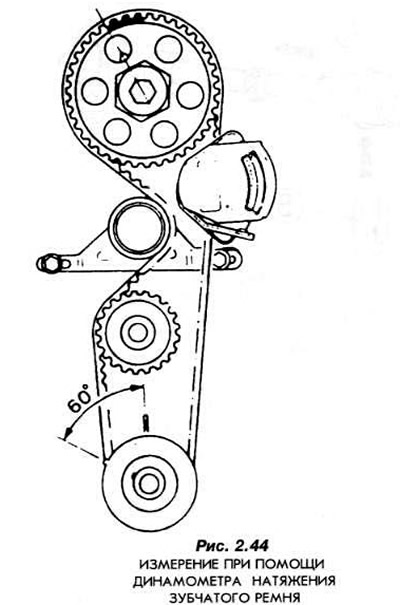

Tension the toothed belt. To do this, you need to do the following:

- move the tensioner and tighten the belt.

- tighten the tensioner bolts.

- turn the crankshaft two turns clockwise (looking at the shaft from the front). Pay attention to the fact that during rotation there is no felt resistance.

- turn the crankshaft to set the piston of the first cylinder to TDC.

- turn the crankshaft 60°.

- install dynamometer 21-113 (pic. 2.44) and determine the tension of the toothed belt.

- the tension of the new belt should be 10-11 divisions on the dynamometer scale, and the tension of the used belt should be in the range of 4-6 divisions.

- adjust the belt tension with the tensioner until you get the correct tension (after each adjustment, it is necessary to measure the tension, maintaining the recommended sequence of actions).

Install both parts of the belt cover.

Install the V-belt pulley on the crankshaft journal.

Screw in new spark plugs.

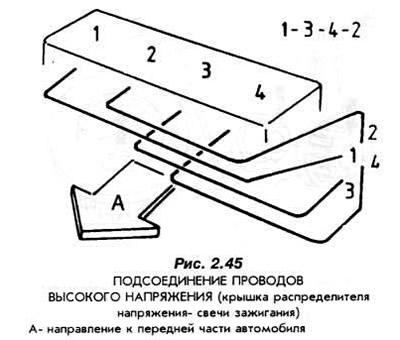

Install the ignition distributor housing with high voltage wires (pic. 2.45).

Install the oil filter. To do this, lubricate the gasket and screw the filter on by hand so that the gasket fits well. Then turn the filter housing an additional 3/4 turn.

Screw in the oil drain plug with a new gasket.

Fill the engine with oil and install the dipstick.

Install the generator and put on its drive V-belt.

Tighten the V-belt so that it flexes 8-10 mm when pressed with your thumb.

Visitor comments