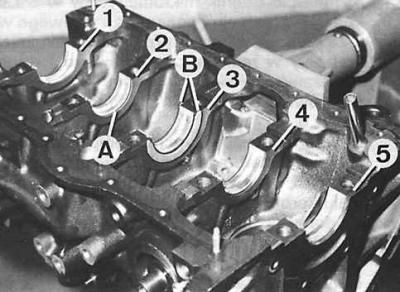

DOHC crankshaft main bearing designations

1–5 - bearing numbers, A - main bearing, B - crankshaft thrust washers

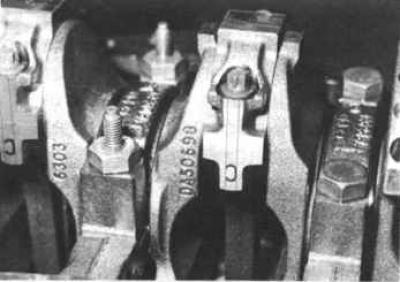

DOHC engine connecting rod cap designation

The top picture is the designation of a complete set with a connecting rod.

The bottom picture is an indication of the correct position of the cover relative to the connecting rod.

1. Insert the dry half-shells of the main bearings into the seats in the cylinder block.

2. Lubricate the working surfaces of the half-liners with oil and install the crankshaft on them.

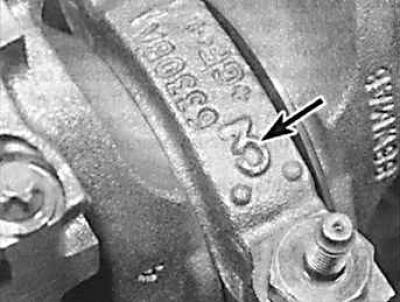

3. Install the main bearing caps together with the oil-lubricated half-shells, the arrows on the main bearing caps must point towards the camshaft drive (the arrow shows the marking of the root caps).

4. Tighten the main bearing cap bolts to the correct torque.

5. Using a set of feeler gauges, measure the end play of the crankshaft. The feeler gauge is installed between the crankshaft journal and thrust washers. The clearance must be within the values specified in subsection 3.2.1. To adjust the gap, thrust washers of various thicknesses can be installed.

6. Rotate the crankshaft to see if it is sticking. If the shaft turns very tight or sticks, it is necessary to disassemble and carefully check.

7. Lubricate cylinders and pistons with piston rings properly fitted.

8. Install the piston-connecting rod assembly in the cylinders, compressing the piston rings with a special tool. Point the arrows on the pistons towards the drive of the gas distribution system (to the front of the engine).

9. Install the connecting rod bearings and connecting rod caps, tightening the bolts to the correct torque.

10. Check the end play of the connecting rods on the crankpins.

11. Install the clutch shaft bearing into the hole in the rear of the crankshaft.

12. Remove the old rear crankshaft seal from the cover. Install the cover on the cylinder block. Lubricate the sealing lips of the new O-ring with fresh engine oil and insert it into the cover using a suitable tubular mandrel with the sealing lips inward.

13. Install the front cylinder block cover.

14. Install the oil deflector and oil pickup tube with a new gasket.

15. Install a new gasket in the oil sump grooves.

16. Apply sealant to areas mating with the O-ring cover.

17. Install the oil sump.

18. Install the flywheel on the crankshaft, tightening the bolts (oil the thread) fastening the flywheel with the appropriate torque.

19. Using the tool, center the clutch disc on the flywheel and install the clutch drive.

20. Install the crankshaft position sensor and oil pressure sensor.

21. Install the oil pump and tighten the mounting bolts to the correct torque.

22. Install oil filter and water pump.

23. Install a new gasket on the cylinder block.

24. Turn the crankshaft so that the pistons are in the middle of their stroke.

25. Install the cylinder head to the cylinder block.

26. Lubricate the threads of the cylinder head bolts with a thin layer of engine oil, install them in place and tighten to the required torque in a certain sequence (see subsection 3.2.1).

27. Lightly coat the camshaft bearings in the head with engine oil and install the camshafts.

28. Lubricate the camshaft bearing caps with a thin layer of engine oil and install them in place in accordance with the markings. The intake camshaft bearing caps are marked R1-R5, and the exhaust camshaft bearing caps are marked L1-L5. The numbering of the covers on the drive side of the gas distribution mechanism.

29. Install the oil supply line to the camshaft lobes.

30. Gradually and sequentially tighten the nuts securing the camshaft caps in sequence. Tighten the fastening nuts by hand by turning them sequentially by 180°until the cover comes into contact with the cylinder head. Tightening sequence: L1 and R1, L5 and R5, L3 and R3. Then hand-tighten the rest of the cap nuts.

31. Tighten the cap nuts to the required torque by turning them through the same angle in the following sequence: L1 and R1, L5 and R5, L3 and R3, L2 and L4, R2 and R4.

32. Check that the crankshaft is in the position corresponding to the setting of the cylinder 1 piston at top dead center on the compression stroke, with the keyway pointing down.

Attention! There are copper elements on the timing chain that are used to properly position the timing mechanism when installing the chain.

33. Lower the chain from above into the casing, while the single copper link of the chain should be at the bottom.

34. Insert the key into the groove of the crankshaft.

35. Set the chain to the inner (big) sprocket, aligning the copper link of the chain with the mark on the sprocket.

36. Install the sprocket on the crankshaft, aligning the groove on the sprocket with the key, while the mark on the sprocket should be strictly below.

37. Insert the lower chain guide from above and screw it on with bolts, the threads of which are coated with an agent that prevents the bolts from unscrewing.

38. Install the chain tensioner hydraulic tappet.

39. Install the chain tensioner lever, the tensioner lever axle and secure it with a lock washer.

40. Check and, if necessary, reset the camshafts. The camshafts must be in a position corresponding to the installation of the cylinder 1 piston at top dead center on the compression stroke, and the alignment lugs for the sprockets must be in line with the top edge of the cylinder head and pointing outward.

41. Install the chain on the exhaust camshaft sprocket, aligning the mark on the sprocket with the middle of the chain section between the copper chain links.

42. Install the sprocket onto the camshaft. In this case, the mark on the sprocket should be in line with the upper edge of the cylinder head and point outward. Screw in the sprocket bolt.

43. Install the chain on the intake camshaft sprocket, aligning the mark on the sprocket with the middle of the chain section between the copper chain links.

44. Install the sprocket onto the camshaft. In this case, the mark on the sprocket should be in line with the upper edge of the cylinder head and point outward.

45. Install the distributor drive gear to the right camshaft.

46. Install the upper timing chain guide.

47. Rotate the crankshaft a few revolutions in the direction of engine rotation.

48. Check the position of the hydraulic tappet plunger.

49. Turn the crankshaft two revolutions in the direction of engine rotation and check the marks on the camshaft sprockets, which should be in line with the top edge of the cylinder head and point outward.

50. Turn the crankshaft one revolution in the direction of engine rotation and check the marks on the camshaft sprockets, which should be in line with the upper edge of the cylinder head and pointing towards each other.

51. Install the oil pump drive chain to the crankshaft sprocket, then install the drive sprocket and chain to the oil pump.

52. Install the oil pump chain tensioner.

53. Check the condition of the sealing ring in the top cover of the timing mechanism. If necessary, remove the old sealing ring and, using a tubular mandrel, install a new ring with the working edges towards the engine.

54. Install the top timing case cover with a new gasket.

55. Install the cylinder head cover.

56. Check the condition of the O-ring in the bottom cover of the timing mechanism. If necessary, remove the old sealing ring and, using a tubular mandrel, install a new ring with the working edges towards the engine.

57. Install the lower timing cover with a new gasket without tightening the mounting bolts.

58. Install the auxiliary belt pulley on the crankshaft and fix it with the old bolt, while centering the lower timing cover, and finally tighten the cover fixing bolts.

59. Unscrew the old bolt from the pulley and screw in a new one, tightening it to the required torque.

60. Install the auxiliary belt tensioner, making sure the tab on the back of the tensioner fits into the corresponding hole in the engine block.

61. Install spark plugs, ignition distributor and high voltage wires.

62. Install the generator, put on the drive belt and adjust its tension.

63. Pour engine oil into the engine.

Visitor comments