Lay dry liners of main bearings in the engine case. Install the support washers so that their grooves are visible.

Lubricate the main bearing shells with engine oil and lay the crankshaft on them.

Install main bearing caps with half shells.

Tighten the bolts securing the main bearing caps to the correct torque.

Check the ease of rotation of the crankshaft in the bearings. If at the same time you find difficulties, it is necessary to loosen the bearing caps one by one in order to find the cap that caused this defect.

Defects usually include:

- poorly selected clearance in the bearing

- contamination of the interacting surfaces of the liners of the motor housing or bearing cover

- in damaged parts

Install pistons with connecting rods. The arrow on the bottom of the piston must point towards the front of the engine (i.e. towards the installed timing belt or chain). Install a ring tie on the piston to compress the piston rings. Make sure that the piston rings are fully engaged in the piston grooves.

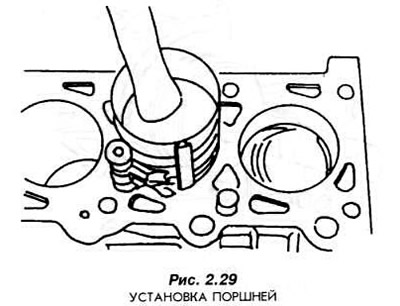

Insert the pistons with connecting rods into the cylinders and with light blows with a hammer handle in the bottom, insert them inside the cylinders (pic. 2.29). Before proceeding with the introduction of the piston into the cylinder, it is necessary to check each time whether the piston rings have entered the grooves and whether the ring tie is correctly installed on the piston.

Lubricate the connecting rod bearings in the lower ends of the connecting rods with oil and apply the oiled bearing caps. Install connecting rod bolts and tighten to recommended torque. Check if the connecting rods turn freely on the crankshaft journals. Rotate the shaft in both directions while checking.

Screw in the oil pressure sensor.

Install the engine front cover (diesel engine timing cover) with oil pump. Pour some engine oil into the pump and turn the pump shaft several times to lubricate the inside of the pump. Before installing, install the front crankshaft oil seal in the cover.

Install the crankshaft rear cover. It must be installed appropriately in relation to the sealing surface of the oil sump.

Install the flywheel and tighten the bolts to the correct torque. During assembly, use new bolts after lubricating their threads with a sealant.

Install the clutch using the centering rod. Tighten the bolts in several stages so as not to bend the clutch cover. The clutch centering rod should be easy to remove. If it is difficult to remove the centering rod, it will be necessary to center the clutch disc again. Instead of a centering rod, you can use the old gearbox input shaft. Further steps for mounting the engine will be presented separately for each type of engine.

Visitor comments