Install the chain tensioner.

Measure the parallelism of the tensioner cam to the end surface of the engine housing (pic 2.30). The difference in distances at the measured points on the cam to the end surface of the motor housing should not be more than 0.2 mm.

Tension the spring and install the tensioner lever on the pin located in the main bearing cap.

Loosen the chain tensioner spring.

Attach the chain gear to the crankshaft. Screw in the central bolt with a washer that secures it.

Install pushers. inserting them from below into the holes in the body.

Mount the camshaft and set it axially using the mounting plate.

Lock the bolts securing the mounting plate with a washer, bending its edges and pressing them against the bolt heads.

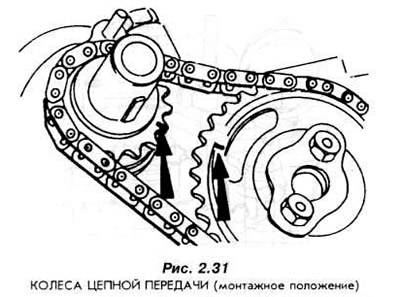

Install the gear on the camshaft along with the chain. The marks on the gears of the crankshaft and camshaft must be in line if the branch of the chain that transmits the driving force is tense (pic. 2.31).

Attach the gear to the camshaft.

Install the oil deflector on the crankshaft journal.

Install the front cover with a new oil seal.

Center the cover with the V-belt pulley. Perform this operation before tightening the bolts securing the cover.

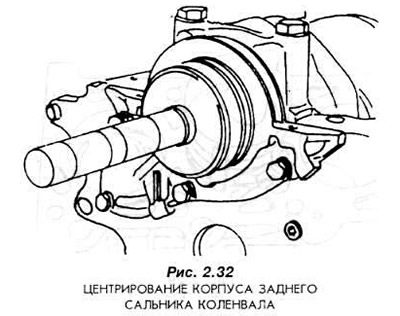

Center the crankshaft rear oil seal housing. The body must contain a new oil seal and tool 21-103 (pic. 2.32).

Screw the body with fixing bolts.

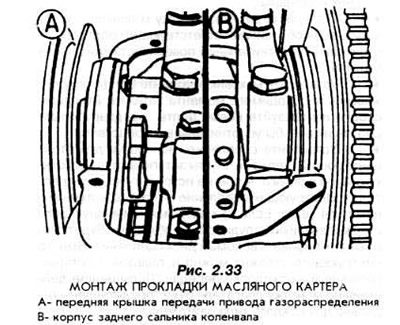

Lay the oil pan rubber gasket on the flange of the engine housing

Lubricate the surface of the motor housing with silicone sealing mass at the point where the stuffing box housing enters the sealing surface of the motor housing.

Paying attention to the appropriate filling of the sealing mass grooves of the gland housing (pic. 2.33).

Install the oil sump and tighten its mounting bolts in three steps. Tighten according to fig. 2.34:

- Stage I - in alphabetical order

- Stage II - in numerical order

- Stage III - in alphabetical order

Note: before installing the oil sump, check whether the distance shown in fig. 2.35 between the wall of the oil pan and its shockproof casing (this distance should not be too large or too small). A bent oil sump must be replaced, as indicated in fig. 2.35 dimensions allow proper engine lubrication.

Install the oil pump.

Install the DIS ignition coil.

Screw on the oil filter with a well lubricated gasket and tighten it by hand.

Install a fuel pump in a carbureted engine.

Install the water pump.

Degrease the seating surfaces of the block head and engine housing under the block head gasket.

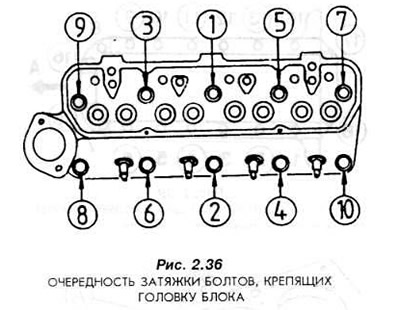

Lay the head gasket on the plane of the engine housing and lay the head of the block. Tighten the new bolts securing the block head in sequence. shown in fig. 2.36.

Tighten the bolts as follows:

- Stage I: 30 Nm

- Stage II: turn the bolts 90°

- Stage III turn the bolts another 90°

Insert push rods lubricated with oil.

Insert the axle with valve levers.

Connect the levers to the push rods.

Fasten the valve lever axle.

Install the thermostat in the head and install the fitting with a new gasket.

Install the water pump pulley.

Adjust valve clearance.

The intake valve clearance is 0.20-0.35 mm. outlet - 0.30-0.35 mm. The valve clearances must be adjusted according to the following cylinder order.

| Divergent valves | Adjustable valves |

| IV cylinder | I cylinder |

| III cylinder | II cylinder |

| I cylinder | IV cylinder |

| II cylinder | III cylinder |

Install the head cover and tighten its fixing bolts.

Screw in the spark plugs.

Install high voltage wires.

Install the intake and exhaust manifolds.

Install the air filter.

Visitor comments