Shine valve.

Clean the valve guide with a carbon cleaner.

Insert the valve into the guide and determine the presence of a gap by pressing the valve in the directions shown by the arrows. The gap should not be felt.

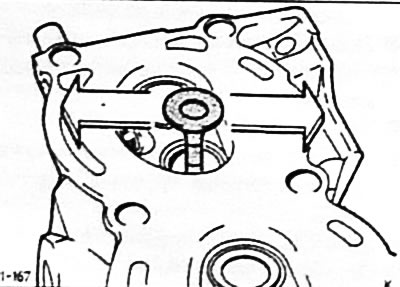

Measure the gap with improvised means: attach a steel square to the cylinder head and press the valve against it. Moving the valve to the square and back, measure the gap with feeler gauges.

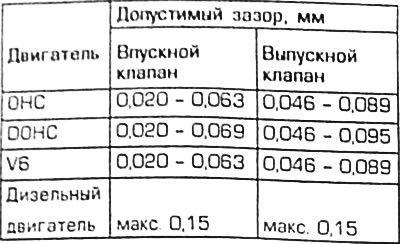

If the gap is greater than that indicated in the table, the holes of the valve guides on the service station must be processed with a reamer of the subsequent repair size. Starting processing is mandatory from the side of the combustion chamber.

Attention: If the holes of the valve guides have been reamed, the valves must be fitted with an allowance in any case.

Visitor comments