The maximum allowable pressure difference in the individual cylinders can be 2.0 bar. If one or more cylinders have a pressure difference greater than 2.0 bar compared to the others, this is an indication of defective valves, worn piston rings or cylinder sliding surfaces. If the wear limit is reached, the engine must be repaired or replaced.

| Engine type and displacement | Compression pressure, bar |

| 4-cyl. petrol | 11-13 |

| 2.4 l; V6 2.9L | 12,4-14,1 |

| V6 2.8L | 11,5-12,5 |

| diesel | 20-25 |

The data given in the table are indicative. Due to the different starter speeds and different designs of compression gauges, it is not always possible to determine the actual compression pressure. Therefore, in most cases, comparative measurements are made between individual cylinders.

The compression test should be done with the engine warm. The engine oil temperature must be at least +30°C. At the same time, the oil filter feels noticeably warm to the touch, otherwise the engine must be warmed up while the vehicle is moving. The engine temperature must not be too high, otherwise the threads in the cylinder head may be damaged when the spark plugs are removed.

Switch off the ignition.

Petrol engine: Disconnect terminal 15 plug at ignition coil.

Engine with catalytic converter: remove the fuel pump circuit fuse, see p. 156.

Diesel engine

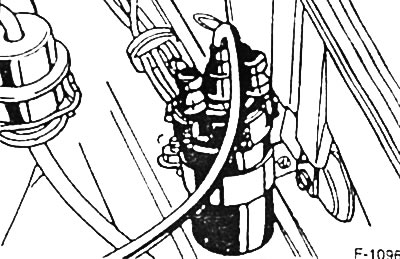

Unplug electrical connector -arrow- for fuel supply switch at high pressure fuel pump.

Attention: If this is not done, when the starter is turned on, diesel fuel will be injected into the combustion chambers by injectors.

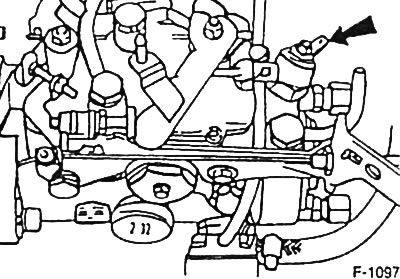

Disconnect multi-pin connector on preheater relay -arrow-.

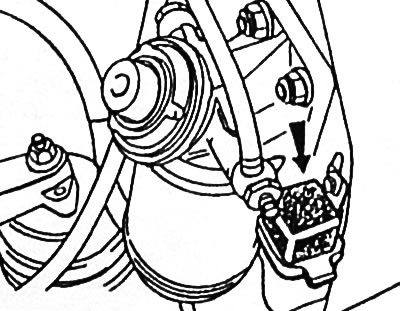

Petrol engine: remove the tips from all spark plugs. For this purpose, a special clamp is used, for example, HAZET 1849.

Finally, blow out the spark plug niches in the cylinder head with compressed air and unscrew the spark plugs with a suitable wrench.

Diesel engine: remove glow plugs, see p. 76.

Turn the engine crankshaft with a starter in order to eject carbon deposits and soot through the holes in the cylinder head.

Attention! Shift the transmission to neutral and apply the handbrake.

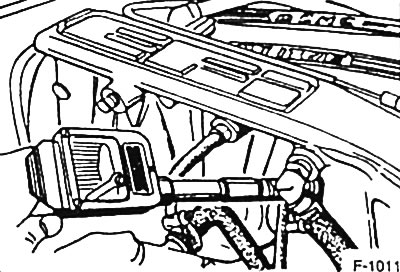

Press the compression gauge in accordance with the service manual against the spark plug / glow plug hole or screw it into this hole.

The assistant should completely drown the accelerator pedal and hold it with his foot during the entire check.

Turn the crankshaft of the engine with a starter about 8 revolutions until the change in readings on the instrument scale stops.

Check all cylinders in succession and compare the results with the prescribed pressures.

Gas engine

After that, screw in the spark plugs and connect the high voltage wires, see p. 51.

Connect the plug connector at the ignition coil.

Diesel engine

Install glow plugs see p. 76.

Connect the multi-pin connector of the preheating relay.

Connect the plug connector of the fuel supply switch at the fuel pump.

Engine with catalytic converter: Replace the fuel pump circuit fuse.

Visitor comments