Attention: If valve drive parts are to be reused, they must be reinstalled in their original locations. In order not to frighten the details in places, it is recommended to prepare an appropriate laying board.

Withdrawal

Remove the cylinder head and lay it on 2 wooden blocks so as not to accidentally damage the open valves, see p. 15.

Detach the retaining springs of the pressure levers from the clips on the spherical pins and remove.

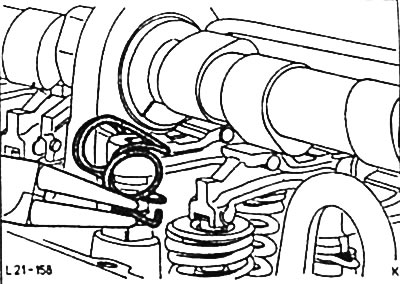

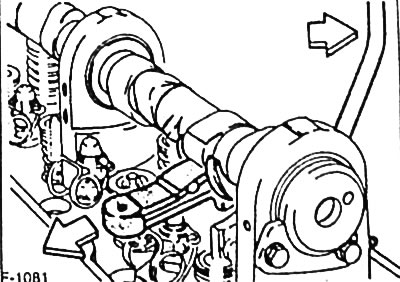

Pull push levers away from camshaft. To do this, turn the camshaft so that the corresponding valve spring is unloaded. Insert the tool FORD 21-005B between the camshaft and the upper plate of the valve spring and sink the plate so that the pressure lever can be removed. If a spring compressor is not available, the valve spring can be carefully compressed with a screwdriver.

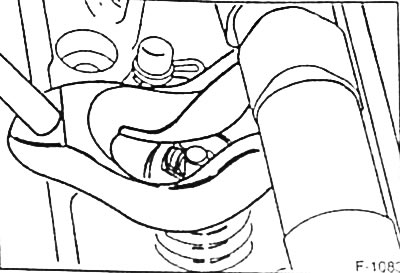

Using the FORD 21-0050 tool, press the valve spring plate down and remove the crackers from the valve recess. To ensure that the valve does not go down when the crackers are removed, place a wooden block in the combustion chamber of the cylinder head.

Attention: Do not damage the valve stem when removing the valve cotters. If the stem is damaged, the valve must be replaced.

Release the valve spring, remove the spring plate and valve spring. Remove all valves in the same way.

Remove the valve from the cylinder head, remove the valve stem seal, see next chapter.

Installation

If the old valves and the old cylinder head are installed, the valve guides must be checked before reassembly. If new valves are installed in the old cylinder head, the valve seats in the cylinder head must first be machined and the valves ground in.

Clean the valves from existing deposits with a scraper and a wire brush. Remove burrs from the valve stems at the contact surfaces of the crackers.

Valve stems and valve guides are easy to lubricate with SAE 80/90 hypoid oil (transmission oil) and insert valves.

Use new valve stem seals see next chapter.

Install the spring and upper spring plate onto the valve.

Using the FORD 21-005B special tool, compress the valve springs, insert the crackers correctly, and then release the springs.

Attention: Do not interchange inlet and outlet valves.

Lubricate the spherical pins with SAE 80/90 hypoid oil and insert the push levers. Rotate the camshaft beforehand so that the corresponding cam points upwards.

Secure pressure levers with retaining springs.

Adjust valve clearances see p. 26.

Install the cylinder head see p. 15.

Visitor comments