Examination

Valve clearance is checked with a feeler gauge between the back of the cam and the tappet (see fig. 2E.1).

Disconnect the flexible crankcase ventilation pipe from the cylinder head cover. Remove the cylinder block cover. Turn the crankshaft of the engine by the pulley fastening nut (can not be rotated by the camshaft pulley) in the direction of its working rotation to a position in which both cams of 1 cylinder will be turned by the working part of the cam up. Check up a backlash of valves of 1 cylinder. inserting the feeler plate between the back of the cam and the follower. Determine the type of valve being tested (inlet or outlet) and compare the value of the measured gap with the required value. If necessary, adjust the clearance of the valve under test.

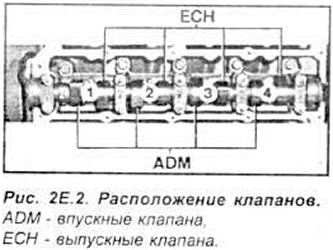

Attention. Valve installation sequence counting from the front of the engine (from the drive side of the gas distribution system) in each cylinder is the same as the first (near the drive of the gas distribution system) is the intake valve and the second is the exhaust valve.

Repeat the above steps for the valves of the remaining cylinders in the injection sequence (1 - 3 - 4 - 2, counting from the drive side of the gas distribution system).

Adjustment

Adjusting the valve clearance consists in replacing the adjusting plate located in the recess of the pusher. Replacing the adjusting plates does not require removing the camshaft if a special tool is used to perform this operation.

Attention. In the process of replacing the valve clearance adjustment plates, the engine pistons should not be exactly at TDC, but a few millimeters below (about 1/4 turn of the crankshaft). This will prevent the valve from hitting the bottom of the piston that is pressed when replacing the adjusting plate.

Turn the tappets in such a way that special pliers can be easily inserted into the cutouts in the bottoms of the tappets after compression to remove the adjusting plates. Set the engine crankshaft to the appropriate position and using a pressure device (tool 21 106) push down pusher (simultaneously opening the valve and compressing its spring) so that with the help of special forceps (21 107) the adjustment plate could be removed.

Measure the thickness of the removed plate and, taking into account the measured clearance and the required nominal value, select a plate from the kit with a thickness that provides the required valve clearance. Insert the matched plate in such a way that the surface with its designation is pointing down (to the pusher).

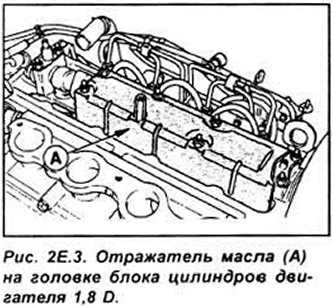

Remove the pressure device. Repeat for other valves Install the cylinder head cover with a new gasket. Attach the elastic pipe of the crankcase ventilation system to the cylinder head cover. Since March 1992, the engine cylinder head cover has been cast from light metal. In addition, an oil deflector is installed under the engine block cover (see fig. 2E.3). which improves camshaft lubrication.

After removing the cylinder head cover, before adjusting the valve clearance, unscrew the oil deflector mounting nuts and remove the oil deflector and tighten the mounting nuts.

Check and, if necessary, adjust the valve clearance.

Unscrew the nuts again, install the removed oil deflector and tighten the fastening nuts again (see fig. 2E.3).

Visitor comments