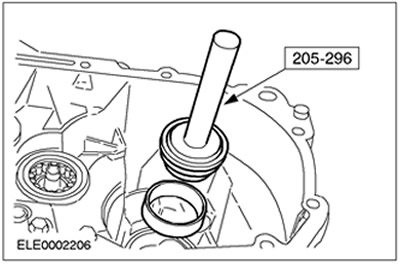

Special tool

| Rear wheel bearing ring/seal installer 205-296 (15-085) |

| 308-045 Transmission housing console oil seal installer (16-015) |

| Input Shaft Oil Seal Installer 308-039 (16-018) |

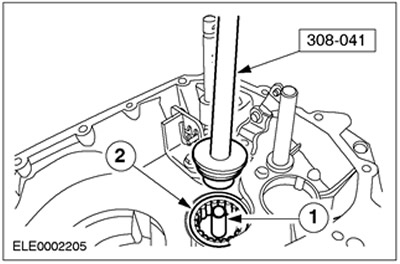

| Input shaft bearing ring installer 308-041 (16-020) |

| 308-076 Input Shaft Retaining Ring Installation Tool (16-031) |

| Valve Spring Compressor 303-060 (21-024) |

| Adapter for 303-060 303-060-02 (21-024-02) |

| Adapter for 303-060 303-060-07 (21-024-07) |

General equipment:

- Press

- Dial indicator

- Tripod with magnetic base for dial indicator

| Name | Specification |

| Universal sealant (Hylomar) | ESEE-M4G1008-A |

| End Cap Sealant | WSE-M4G323-A4 |

| Sealant for gearbox housing | WSK-M2G348-A5 |

| transmission fluid | WSD-M2C200-C |

1. Carefully clean and check all parts before assembly.

- Lubricate all work surfaces. For this, transmission fluid is used.

2. Install the output shaft roller bearing together with the bearing inner race.

- 1. Install the oil nozzle.

- 2. Install the roller bearing.

3. Install the differential bearing inner race.

4. Install the 5th/Reverse select shaft with shift lock bushing.

- 1. Shift lock sleeve

- 2. 5th/reverse select shaft

5.

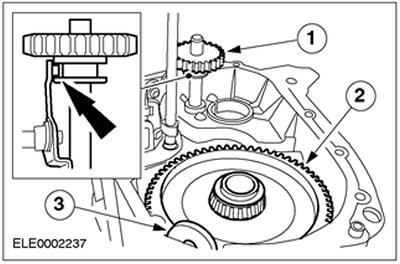

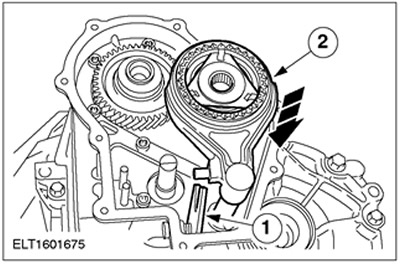

NOTE: Installation position of the reverse idler gear

Install the reverse idle gear, differential assembly and permanent magnet.

- 1. Idler reverse gear

- 2. Differential

- 3. Permanent magnet

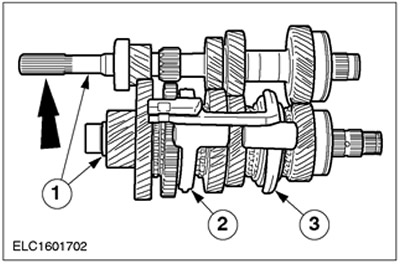

6. Prepare input and output shafts for installation.

- 1. Engage the input and output shafts.

- 2. Move the 1st/2nd shift fork to the installation position.

- 3. Move the 3rd/4th shift fork to the installation position.

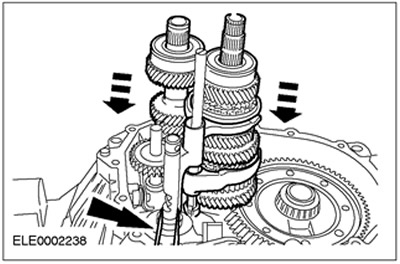

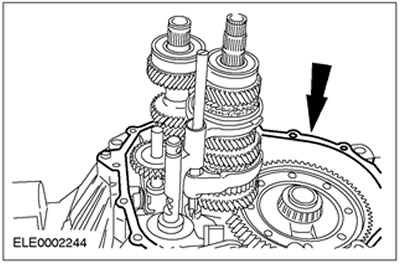

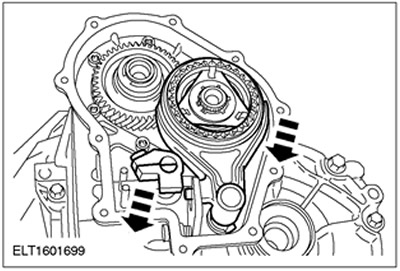

7. Install the primary and secondary shafts.

- To facilitate installation, connect a rubber belt to the gear selector shaft.

- Insert the input shaft to a depth of approximately 50 mm and turn slightly to the side.

- Insert the output shaft up to the level of the input shaft and re-engage the gears.

- Check the position of the input and output shafts.

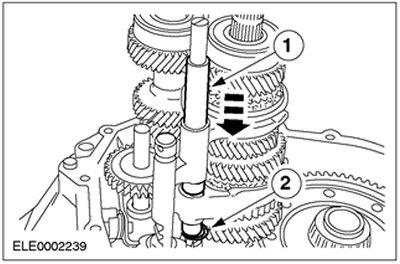

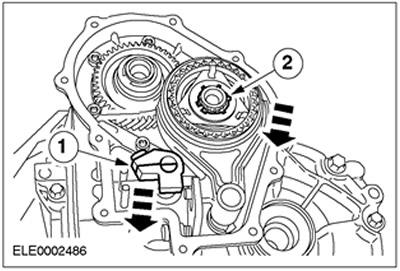

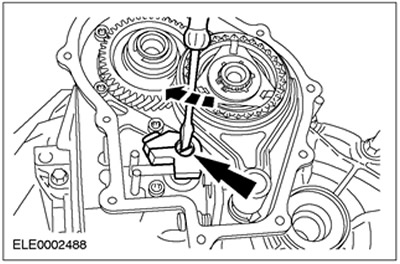

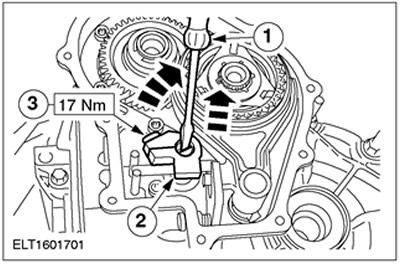

8.

NOTE: Install a new lower retaining ring.

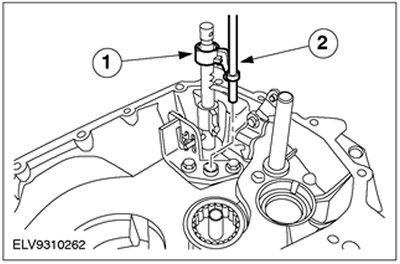

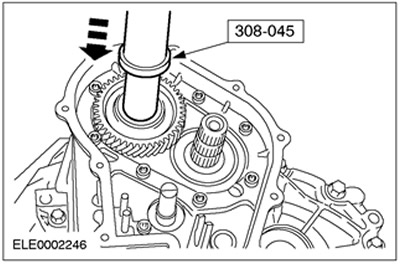

Install the selector shaft guide bush.

- 1. Install the guide bush.

- 2. Install the lower retaining ring.

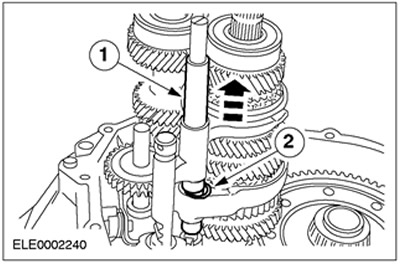

9.

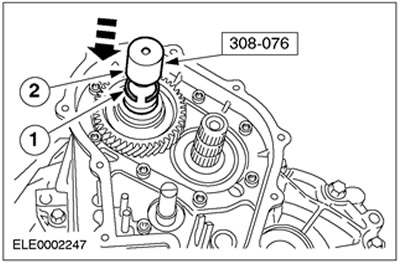

NOTE: Install a new top retaining ring.

Connect the upper circlip for the selector shaft guide bushing.

- 1. Pull up the guide bush.

- 2. Install the top retaining ring.

10. Shift the internal shift linkage to 5th gear.

- Turn the gear selector shaft clockwise until it reaches the reverse gear/5th gear shift channel, then push it down.

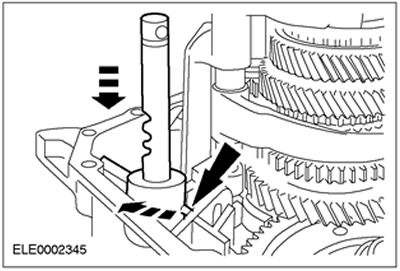

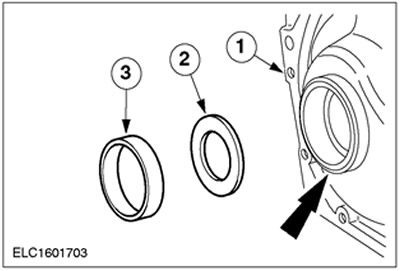

11. Install the shim and secure it with a center punch.

- 1. Gear box

- 2. Gauge (3.8 mm thick)

- 3. Inner bearing ring

12.

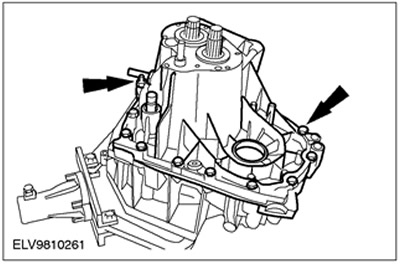

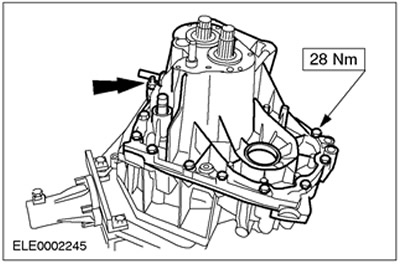

NOTE: Thoroughly clean the mating surface.

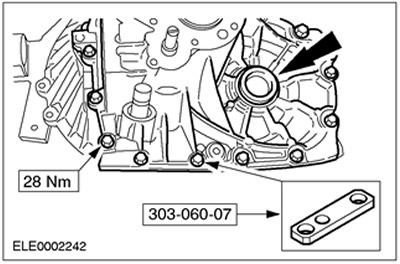

Assemble the gearbox housing.

- Connect the special tool with a long bolt.

- Insert process plugs.

- Tighten the bolts.

- Rotate the gearbox 180 degrees.

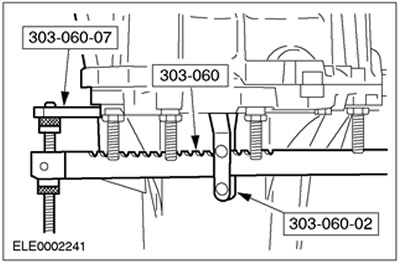

13. Connect the special tool. Remove technological plugs.

14. Prepare differential for measurements.

- Rotate the differential assembly at least ten times to allow the bearings to settle into a stable position.

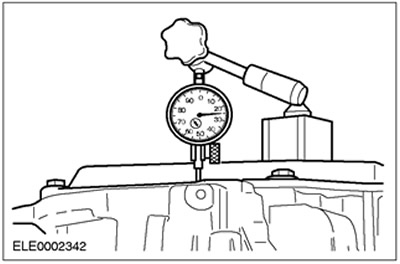

- Set up a dial indicator with a tripod with a magnetic base and set it to «zero».

15.

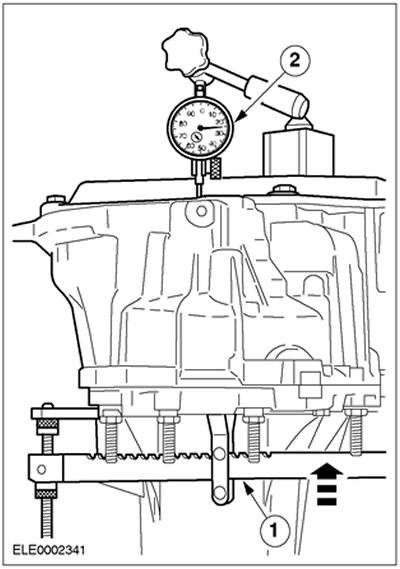

NOTE: Repeat the previous and this step three times and calculate the average value.

Measure the end play of the differential.

- 1. Using the special tool, lift up the differential.

- 2. Take readings.

- Example:

- 1st measurement measurement result: 0.73 mm

- 2nd measurement measurement result: 0.74 mm

- 3rd measurement measurement result: 0.72 mm

- Average value = 0.73 mm + 0.74 mm + 0.72 mm/3 = 0.73 mm

- The thickness of the washer used must be rounded down for results up to 0.05 or less after the decimal point, and rounded up for results starting at 0.06 or more after the decimal point.

- Adjusting shims with a thickness of 0.1 mm to 1.1 mm with a resolution of 0.1 mm are provided.

- Move on to the next item.

16. Determine the gasket thickness for installation (example).

- Shim Thickness =

- Gauge thickness (3.80 mm) +

- Average value (0.73mm) +

- Bearing preload (0.14) -

- Belleville washer thickness (4.42 mm) =

- 3.80 mm + 0.73 mm + 0.14 mm - 4.42 mm = 0.25 mm

- The thickness of the shim should be 0.25 mm, after rounding - 0.20 mm.

17. Separate sections of a case of a transmission.

- Insert the top process plugs.

- Rotate the gearbox 180 degrees.

- Detach the dial indicator together with the tripod and the special tool.

18. Remove the inner race of the bearing along with the shim.

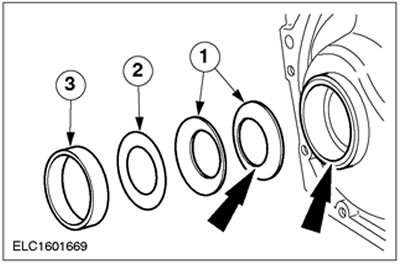

19.

NOTE: Belleville washers touch on inside diameter.

Install an adjusting shim (rounded) thickness and secure it with a center punch.

- 1. Belleville washers

- 2. Adjusting lining of the calculated thickness.

- 3. Install the inner race of the bearing and fix it by punching the crankcase edge.

20. Apply sealant evenly to the crankcase of the transmission.

21.

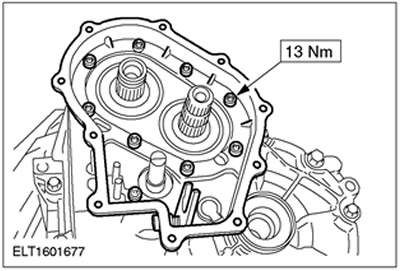

NOTE: Torque the studs to 33 Nm.

Assemble the gearbox housing and tighten the bolts evenly.

22.

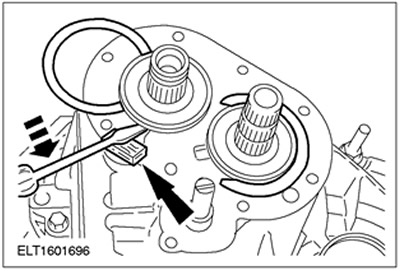

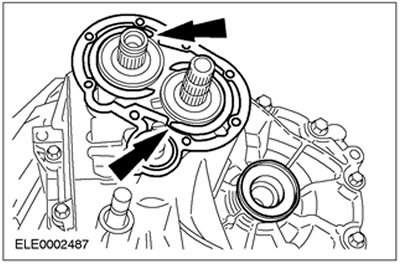

NOTE: Install new retaining rings on the input and output shafts.

NOTE: Use a wooden block.

Install circlips on input and output shafts.

23.

NOTE: Rotate the circlips so they are seated in the gasket cutouts.

NOTE: Install a new seal on the 5th gear housing.

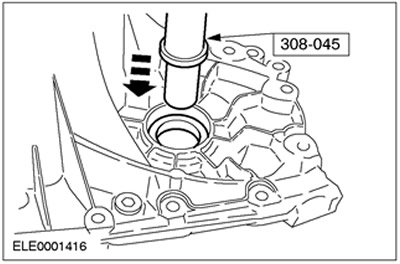

Install the 5th gear case seal. Insert process plugs.

24. Install the 5th gear housing.

25.

CAUTION: Disconnect the gearbox from the assembly stand and perform the following steps on the press.

NOTE: The gearbox housing must not rest on the press table. Rest the splines of the input shaft on the press.

Press the 5th gear onto the input shaft using a press.

- Disconnect the gearbox from the assembly stand.

- Press on the 5th gear using a press.

- Support the gearbox on the assembly stand.

26.

NOTE: Install a new 5th gear retaining ring.

Install the 5th gear snap ring.

- 1. Install the circlip on the special tool.

- 2. Install the special tool and fit the circlip.

27.

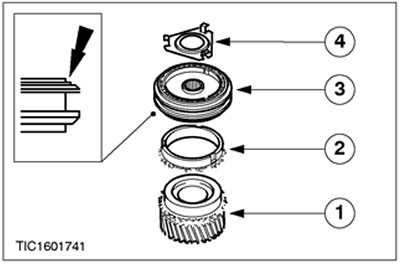

NOTE: Synchronizer installation position identification.

Assemble the 5th gear synchronizer.

- 1. 5th gear

- 2. Synchronizer ring

- 3. Synchronizer

- 4. Lock bar

28. Install the 5th gear synchronizer together with the gear selection fork.

- 1. Turn the drive disk up.

- 2. Install the 5th gear synchronizer so that it reaches the drive plate.

29.

NOTE: Do not tighten the gear selection hub bolt at this stage.

NOTE: Install a new 5th gear retaining ring.

Install the 5th gear synchronizer and selector fork.

- 1. Install the gear selector finger.

- 2. Install the 5th gear synchronizer snap ring.

30.

NOTE: Only install with the transmission in neutral.

The installation position of the gear selector shaft locking mechanism.

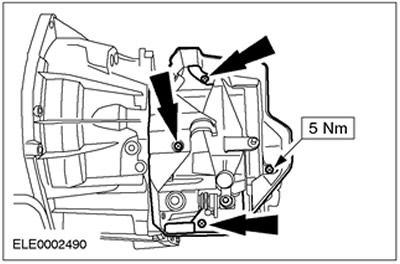

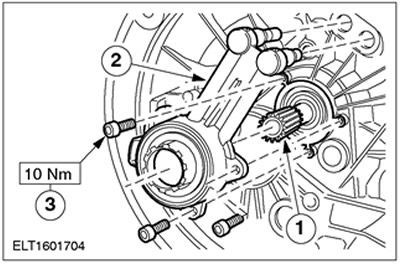

31.

NOTE: Only install with the transmission in neutral.

Establish mechanisms of blocking of a choice of transfers.

- Apply universal sealant (Hylomar) for carving.

- 1. Main locking mechanism

- 2. 5th gear lock mechanism

32. Establish an arm of cables of switching and a choice of transfers. Install covers.

33.

NOTE: Install the 5th gear lock mechanism.

Engage 5th gear. Press down the gear selector fork together with the gear selector finger.

34. Engage 5th gear. Turn the gear selector shaft clockwise for its entire travel.

35. Engage 5th gear. Turn the selector shaft clockwise to full travel and insert the shaft.

36. Adjust the gear selection finger.

- 1. Turn the selector shaft clockwise and push it down.

- 2. Raise the gear selector finger to remove the end play.

- 3. Tighten the bolts in this position.

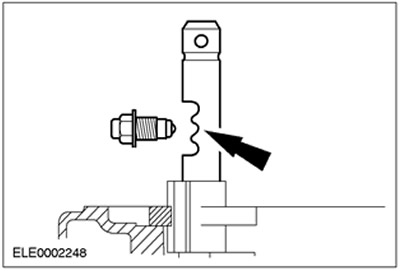

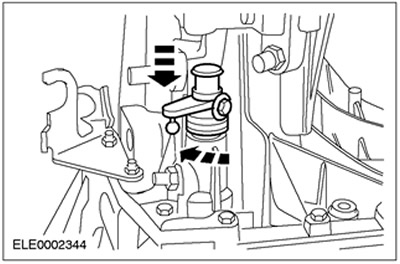

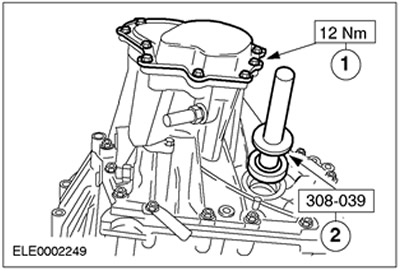

37. Install the end cap and input shaft oil seal.

- 1. Install the end cap using end cap sealant.

- 2. Insert the input shaft oil seal until it clicks into place.

- Insert process plugs.

38. Install the shift lever.

- 1. Install retaining ring.

- 2. Install the cover.

39. Install the shift cable cover.

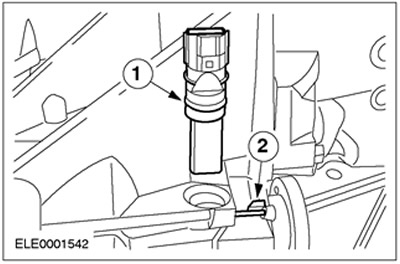

40. Install the vehicle speed sensor (VSS).

- 1. Connect the VSS sensor.

- 2. Insert the pin.

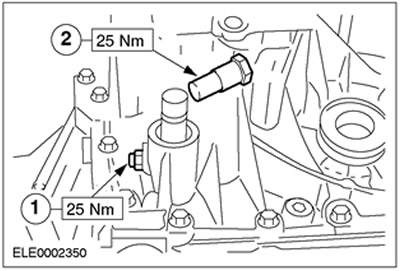

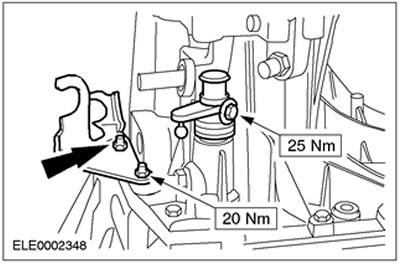

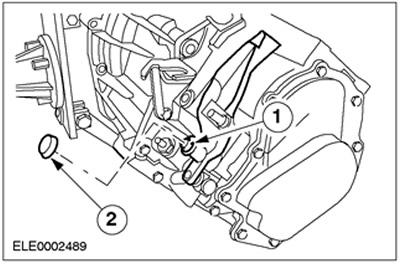

41. Install the input shaft oil seal and clutch slave cylinder.

- 1. Align the position of the input shaft oil seal.

- 2. Check the position of the clutch slave cylinder.

- 3. Tighten the bolts evenly. While doing this, press the input shaft oil seal into the gearbox housing.

42. Disconnect the transmission assembly from the assembly stand.

Visitor comments