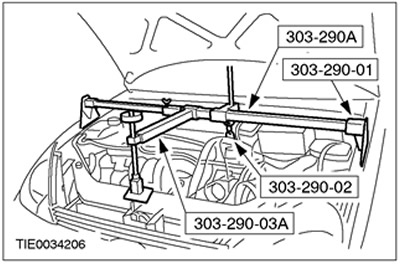

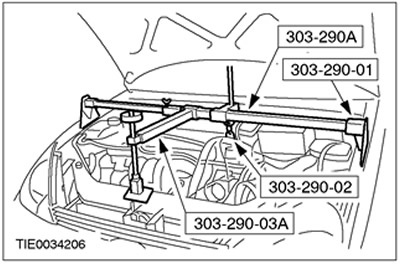

Special tool

| Mounting bracket for 303-290A engine (21-140A) |

| Adapter for 303-290A (21-140) 303-290-01A (21-140-01A) |

| Adapter for 303-290A (21-140) 303-290-02 (21-140-02) |

| Adapter for 303-290A (21-140) 303-290-03A (21-140-03A) |

General equipment:

- Fixing clamp

- Jack for gearbox

| Name | Specification |

| Transmission Fluid for Manual Transmission | WSD-M2C200-C |

Installation

1.

CAUTION: Be sure to install the two guide bushings.

NOTE: Secure the transmission to the transmission jack using the retaining strap.

Using an appropriate gearbox jack, install the gearbox in the drive axle assembly.

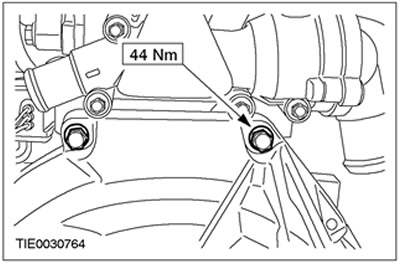

2. Screw the left bolt of a transmission.

3. Lower the car.

4. Screw in the top bolts of a transmission.

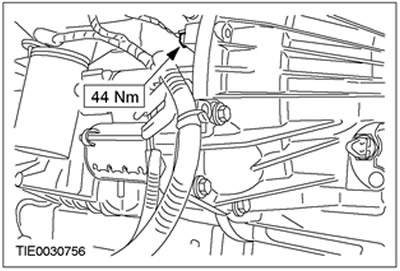

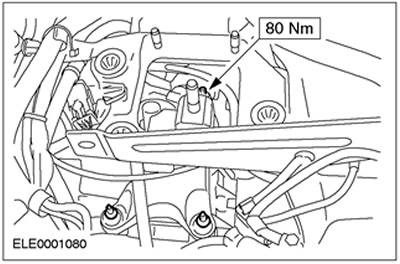

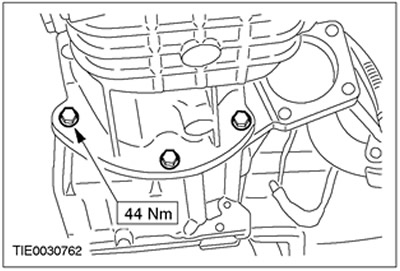

5. Install the rear engine mount bracket.

6. Lift the engine/gearbox assembly using the special tools.

7.

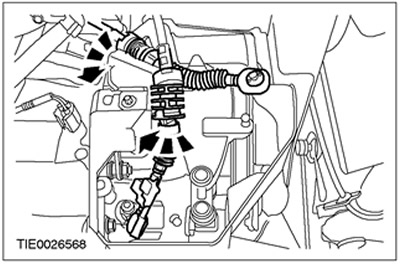

NOTE: Install new nuts for rear engine mount.

Install the rear engine mount.

8. Disconnect special tools.

9. Raise the vehicle. Refer to Section 100-02 for more information.

10. Screw in the bottom bolts of a transmission.

11. Screw in the right bolts of a transmission.

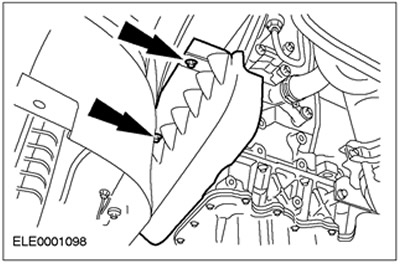

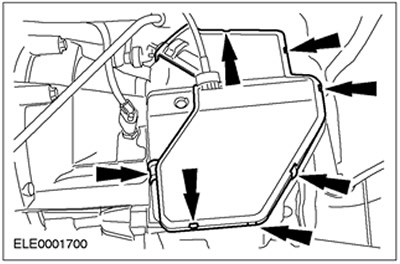

12. Install the accessory drive belt cover.

13.

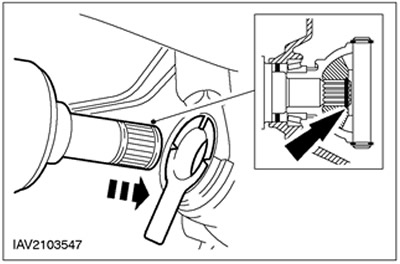

CAUTION: Support axle shaft. The inner hinge of the axle shaft should not be deflected by an angle exceeding 18 degrees; the outer hinge of the axle shaft - at an angle exceeding 45 degrees.

CAUTION: Be careful not to damage the axle shaft oil seal.

CAUTION: Be sure to install the retaining ring correctly.

NOTE: Install a new retaining ring.

Connect the left axle shaft to the gearbox.

14.

CAUTION: Support axle shaft. The inner hinge of the axle shaft should not be deflected by an angle exceeding 18 degrees; the outer hinge of the axle shaft - at an angle exceeding 45 degrees.

CAUTION: Be careful not to damage the axle shaft oil seal.

Connect the right semiaxle and an intermediate shaft to a transmission.

15.

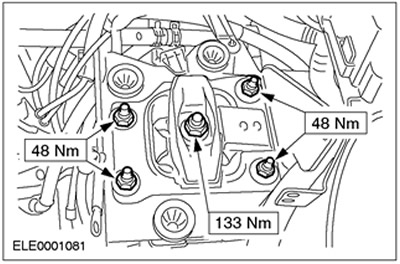

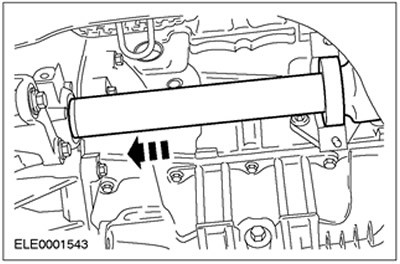

NOTE: Replace intermediate bearing cap and self-locking nuts.

Establish a cover of the intermediate bearing of an intermediate shaft.

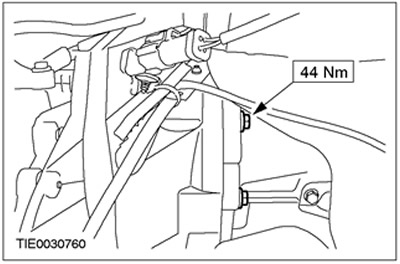

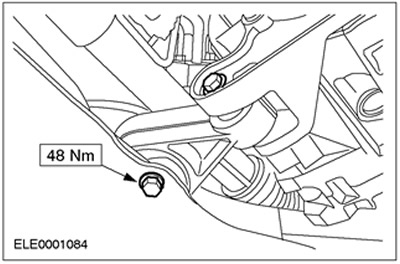

16. Install roll limiter.

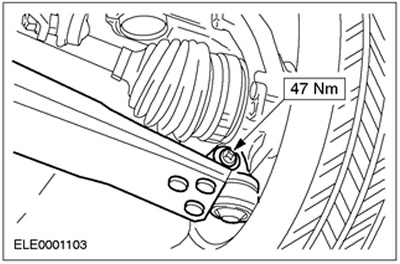

17. Connect the ball joint of the lower suspension arm to the steering knuckle (left side shown).

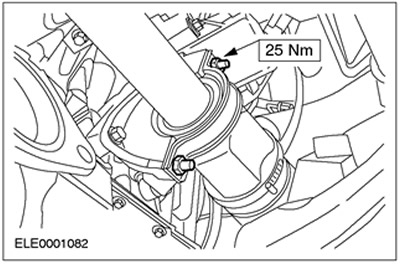

18. Connect a reception exhaust pipe to a final collector.

19. Install the starter.

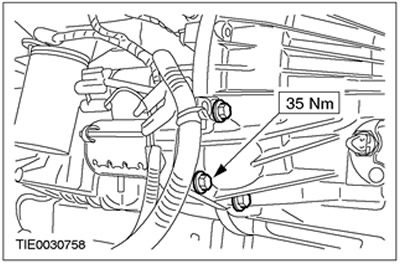

20. Connect the power steering pipe bracket and ground wire.

21. Connect the shift cables to the bracket and turn the support bushings counterclockwise.

22. Fill in the transmission fluid to a level of 5-10 mm below the lower edge of the control hole.

23. Install the shift cable cover.

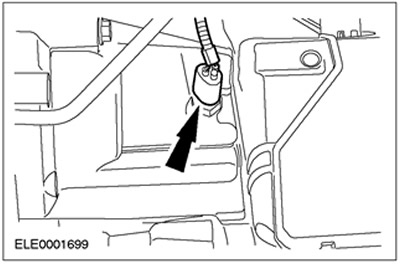

24. Connect the vehicle speed sensor connector (VSS) (in the presence of).

25. Connect the reversing light switch connector.

26. Lower the car.

27.

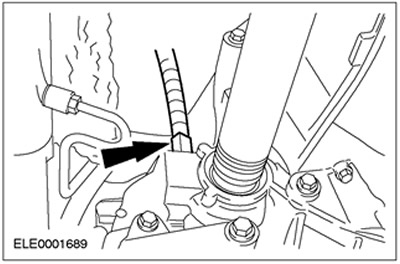

WARNING: If brake fluid comes into contact with the paintwork, the affected area must be washed immediately with cold water.

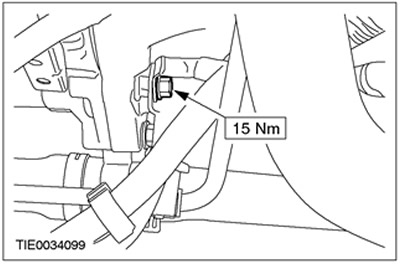

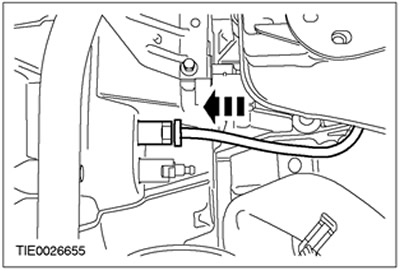

NOTE: Make sure the spring clip is installed correctly.

Connect the clutch slave cylinder pipe. Install the spring clip.

28. Bleed the hydraulic clutch system. Refer to Section 308-00 for more information.

29. Install the battery shelf. Refer to Section 414-01 for more information.

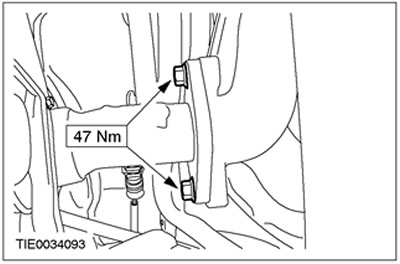

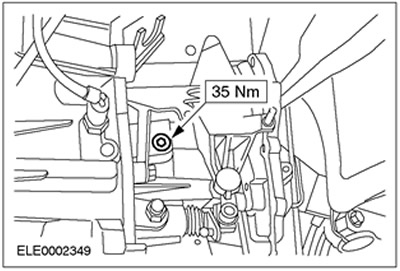

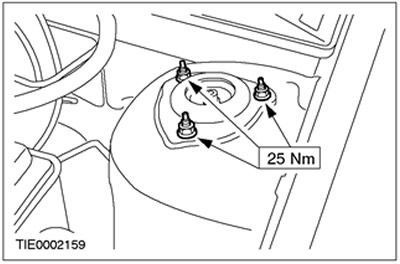

30. Tighten the upper suspension strut nuts (at both sides).

31. Adjust shift cables. Refer to Section 308-00 for more information.

Visitor comments