New or replacement shafts are mainly supplied in «protective cage», to prevent the hinges from twisting during transport. Remove the cage only after installation and make sure that the cuffs are not damaged. To remove the drive shafts, you must first separate the ball joint of the lower control arm from the swivel bearing. The transverse arm in this case remains in the mounted state.

Dismantling the right shaft

|

PROCEDURE |

- Set the parking brake and loosen the wheel hub nut.

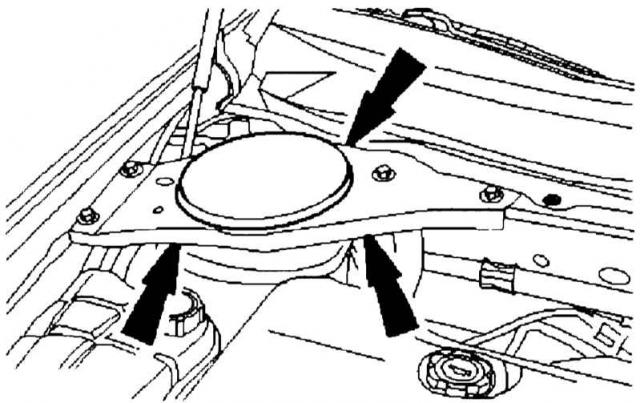

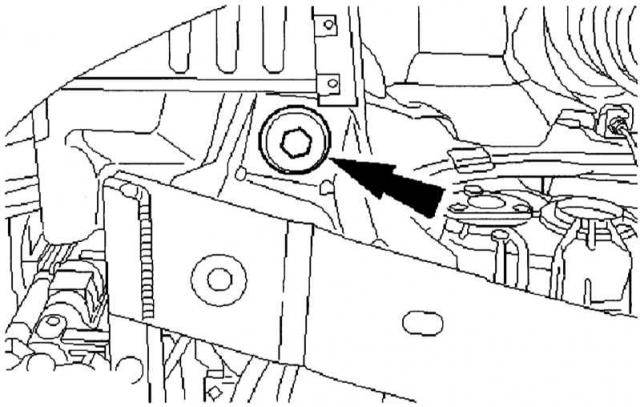

- In the engine compartment, press the locking cap of the right suspension strut bearing (shown by arrow).

Wring out a locking cover of the right bearing of an amortization rack (shown by arrow). |

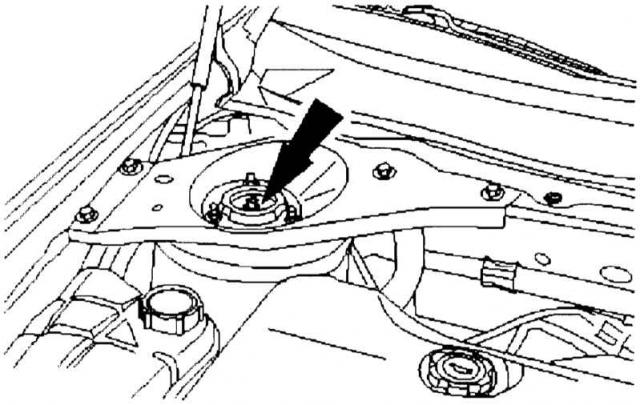

- Rotate strut connecting rod (indicated by an arrow) with an Allen key and loosen the nut in the suspension strut pin about five turns.

Loosen the nut in the suspension strut pin about five turns. |

- Jack up the front of the vehicle securely, block the rear wheel with a wedge and remove the right wheel.

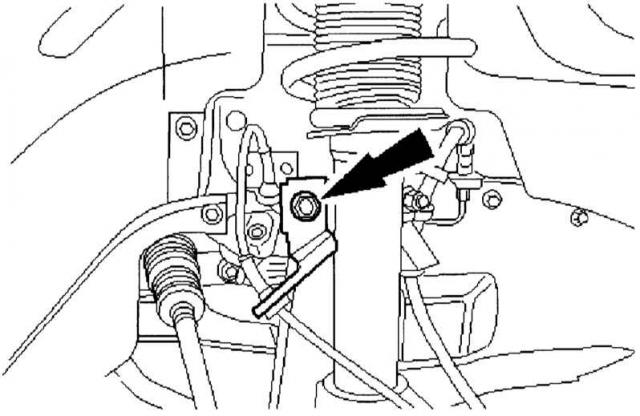

- Remove the stabilizer link in the wheel arch (arrow) from the shock absorber.

Removing the stabilizer link (arrow) from the shock absorber. |

- Loosen the wheel hub nut and mark it with a punch. Nuts should be reused as much as possible.

- Remove the lower control arm ball joint from the swing arm. The transverse arm in this case remains mounted. In the event that the transverse arm must be dismantled for other work, we will describe this dismantling separately. In models with diesel engines, the lower engine cover must first be dismantled. If your Mondeo is equipped with gas-charged headlights, then you need to remove the headlamp leveling sensor from the left lower wishbone.

- Dismantle now the lower protection of the radiator (five attachment points) and then secure the lowering side of the subframe with a hydraulic car jack.

- To remove the control arm, lower the subframe on the side where the driveshaft will be removed. The lowering side is then securely secured with a hydraulic vehicle jack.

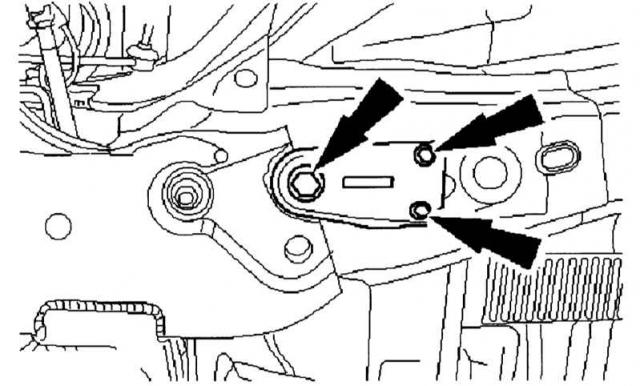

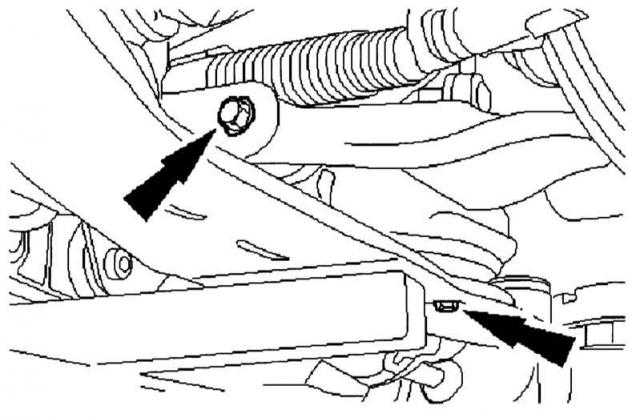

- Now unscrew the rear bolts of the sub frame and the frame holder (indicated by arrows).

Unscrewing the three bolts of the sub frame and frame holder (indicated by arrows). |

- Next, on the opposite side, loosen the rear sub-frame and frame holder screws approximately five turns to...

- then completely unscrew the front bolt from the mounting side (indicated by an arrow). On the opposite side, loosen the screws about five turns.

On the mounting side, fully unscrew the front bolt (indicated by an arrow), and on the opposite side, loosen the screws about five turns. |

- To get to the rear control arm screws, now lower the sub frame using a hydraulic jack.

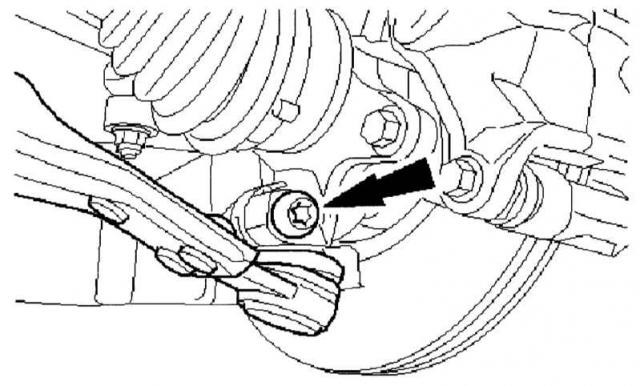

- In order not to damage the rubber bearing of the control arm, it is necessary before releasing the ball joint clamping screw (indicated by an arrow), be sure to lower the subframe.

Loosen the clamping screw of the ball joint (indicated by an arrow). |

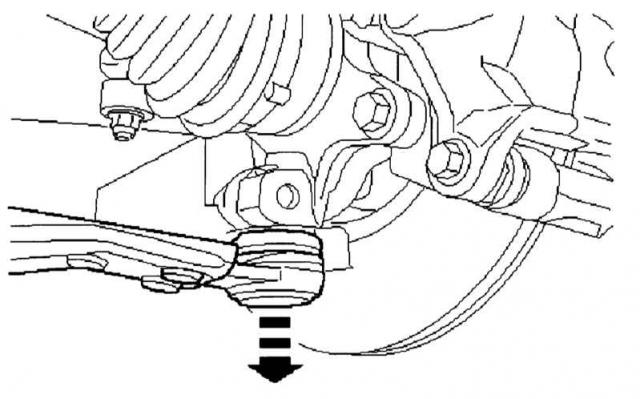

- Protect the bellows on the ball joint from damage with a soft cloth and remove the ball joint from the pivot bearing (arrow). First dismantle the thermal protection.

Disconnect the ball joint from the swivel bearing (arrow). |

- Remove the lower control arm (indicated by an arrow), use new screws and nuts for installation.

Removing the lower wishbone (indicated by an arrow), dispose of the old screws and nuts after dismantling. |

- Now support the drive shaft as the maximum allowable bending angle of the inner joint must not exceed 18°and the outer joint 45°. If this happens, the hinge cannot avoid damage.

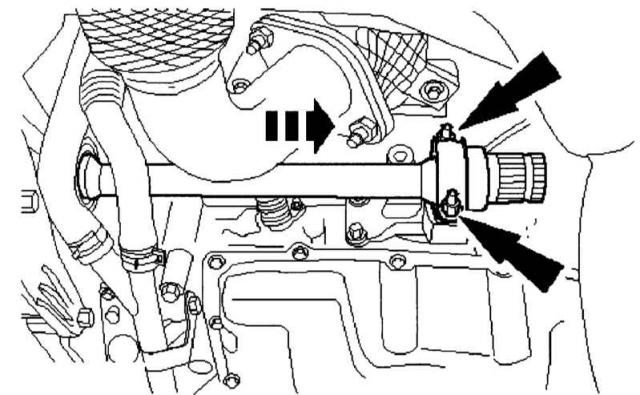

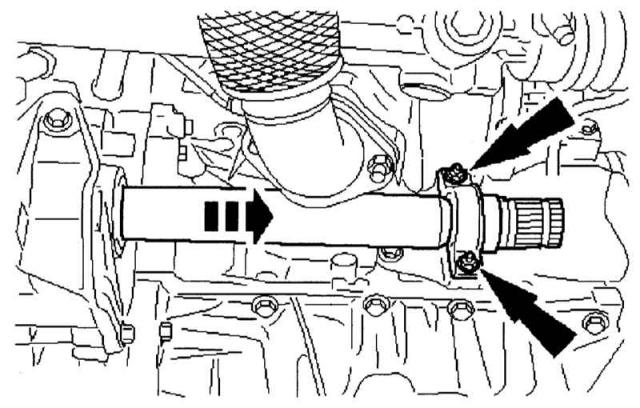

- Remove the drive shaft from the intermediate shaft with a suitable puller, lay it aside and secure. Remove the safety ring first and dispose of it.

- Now press the drive shaft out of the wheel hub using a suitable three-arm puller.

|

|

Mounting the right shaft

|

PROCEDURE |

- First of all, replace all self-locking nuts and lightly lubricate the threads of the axial shaft and the spline before mounting.

- Support the new drive shaft so that its hinges do not twist, and place it under the front of the vehicle.

- Push the shaft onto the intermediate shaft and secure with a new retaining ring.

- Press the outer cam of the shaft against «pre-lubricated» spline connection of the wheel hub. Help yourself with lightly targeted hammer blows if necessary (rubber hammer) along the wheel hub. Once there are enough threads, pull the shaft cam all the way together with the wheel hub nut.

- Don't fully tighten the nut yet, but...

- ...First mount the stabilizer link on the suspension strut.

- Then mount the control arm ball joint on the swing arm.

- If you completely dismantled the control arm, then install it now with new screws and nuts. Tighten the screws completely only when you put your Mondeo back on the wheels.

- When mounting the transverse arm on a pivot bearing, do not forget the thermal protection.

- Insert the ball joint mounting screws from behind and tighten to 83 Nm.

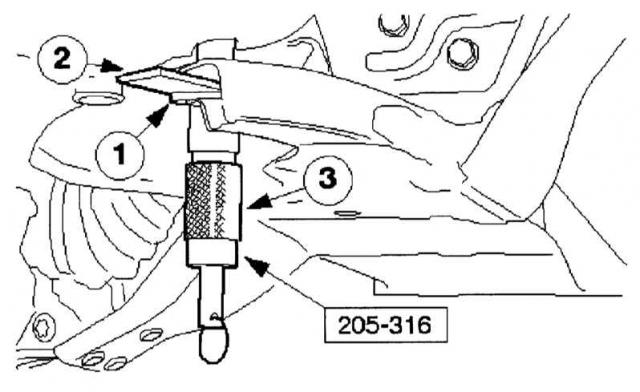

- Now align the subframe by pushing. This is a temporary measure: Ford workshops use a special tool for this (205–316) and suitable washers. The pros do it this way:

- They use a washer 1 with an inner diameter of 22 mm, an outer diameter of 44 mm and a thickness of 5 mm. This washer is placed on top of the lower alignment hole on the subframe. The guide pin 2 is then inserted through the subframe alignment holes and the washer. After that, move the mounting plate 3 along the washer into the groove of the special tool and tighten the bushing of the guide pin.

Sub Frame Leveling: For professionals only.

1 Washer, 2 Guide pin, 3 Mounting plate. |

Aligning in this way, you insert the sub-frame screws and the frame holder. When tightening the screws (external 10 Nm, internal 142 Nm) the auxiliary frame must not move. Now insert the front screws and tighten them to 142 Nm. After that, the auxiliary frame can no longer be moved. Lower the hydraulic jack and remove the special tool along with the U-washer. Place the vehicle on the wheels and first tighten the wheel hub nut to 290 Nm. Now tighten the front control arm screw to 80 Nm plus 60°and the rear control arm nut to 90 Nm plus 60°. Complete all work in reverse order. Tighten the connecting rod nut with a torque of 59 Nm. Take your Mondeo for a test drive and see if it drives straight and if the steering wheel return forces are equal in both directions. If not, then the car must be measured. If the test drive went without problems, then finally check all screw connections for tight fit. |

|

Removing the left shaft

|

PROCEDURE |

- Proceed as for the removal of the right drive shaft up to step F

- Support the drive shaft now, as the maximum permitted bending angle of the inner joint must not exceed 18°and the outer joint 45°. If this happens, the hinge cannot avoid damage.

- Remove the safety ring from the transmission side and dispose of it. Now pull the drive shaft out of the gearbox, being careful not to damage the O-ring of the radial shafts in the gearbox housing, and carefully lower the shaft. Drain the leaking transmission oil into a clean container and, after repair, using a special can, drain it back into the gearbox.

- To prevent road grime from getting in, cover the transmission opening with a clean rag.

- Now press the drive shaft out of the wheel hub with a three-arm puller.

|

|

Mounting the left shaft

|

PROCEDURE |

- Be sure to replace all self-locking nuts and lightly lubricate the axial shaft threads and spline before mounting.

- Insert the new shaft into the gearbox first.

- Then install as described in this procedure for the right drive shaft. After that, do not forget to check the transmission oil level.

|

|

Removing the intermediate shaft

|

PROCEDURE |

- Proceed in the same way as in the section «Removing the right drive shaft» up to stage 18.

- Separate both drive shafts and lay both shafts aside in a safe place. Make sure that their hinges are not twisted.

- When installing, use a new retaining ring. And then it all depends on the type of engine.

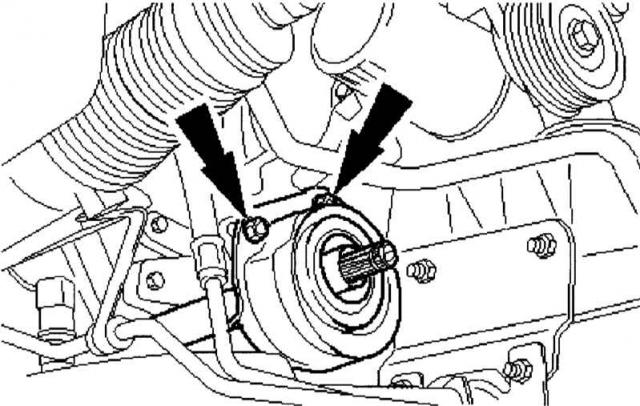

Mondeo with Duratec-VE engine - Remove the nuts on the intermediate bearing cap (indicated by arrows) and dispose of with lid. Drain the escaping gear oil into a prepared, clean container for reuse.

Remove the locknuts on the intermediate bearing cap (indicated by arrows) and dispose of with lid. |

- Pull the shaft out of the gearbox and cover the hole with a clean rag. Take care not to damage the sealing ring of the radial shafts in the gearbox housing.

Mondeo with DuraTorg-DI engine

- Remove the nuts on the intermediate bearing cap (indicated by arrows) and dispose of with lid. Drain the escaping gear oil into a prepared, clean container for reuse.

Remove the locknuts on the intermediate bearing cap (indicated by arrows) and dispose of with lid. |

Mondeo with Duratec-HE engine

- Remove the nuts on the intermediate bearing cap (indicated by arrows) and dispose of with lid. Drain the escaping gear oil into a prepared, clean container for reuse.

Remove the locknuts on the intermediate bearing cap (indicated by arrows) and dispose of with lid. |

|

|

Mounting the intermediate shaft

|

PROCEDURE |

- Mount the intermediate shaft, taking into account the vehicle engine, in reverse order. Tighten the intermediate bearing with a force of 25 Nm. Pay attention not to damage the former sealing ring of the radial shafts. It will be even better if you install a new ring.

- also use new locknuts and bearing cover for mounting.

- Complete the installation of the intermediate shaft in reverse order depending on the engine type and proceed further.

|

|

Visitor comments