Special tool

| Pinion Oil Seal Remover 205-078 (15-048) |

| Differential bearing ring remover 205-176 (15-074) |

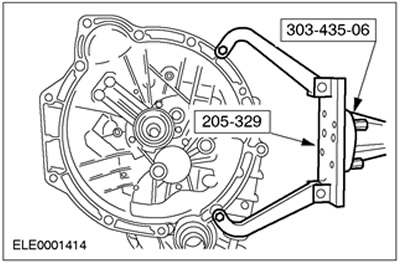

| Engine/Differential Assembly Stand 205-329 (15-105A) |

| Installer 308-045 (16-015) |

| 5th gear puller from input shaft 5th gear puller from input shaft 308-082 (16-035) |

| Support bracket for 303-435 303-435-06 (21-031V) |

General equipment: Assembly stand.

1.

CAUTION: Handle the dual synchronizer elements with care.

General note

- Protective pads must be installed on the vise jaws during all operations.

- Use a copper or plastic mallet to avoid damage to the gearbox components.

2. Mount the gearbox on the assembly stand.

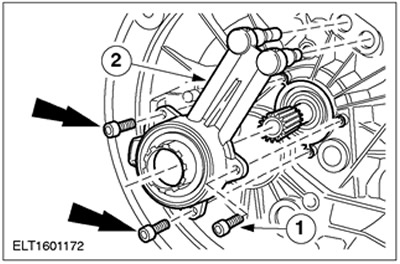

3. Remove the clutch slave cylinder.

- 1. Turn out bolts.

- 2. Remove the clutch slave cylinder.

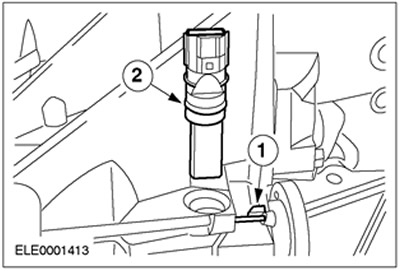

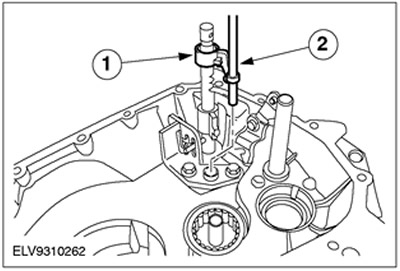

4. Remove the vehicle speed sensor (VSS).

- 1. Remove the pin.

- 2. Remove the VSS sensor.

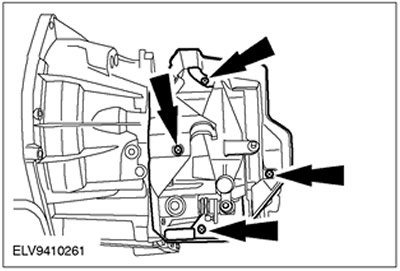

5. Remove the shift cable cover.

6. Remove the gear selection lever.

- 1. Remove the protective cover.

- 2. Remove the retaining ring.

7. Remove brackets for shift cables and gear selection. Remove the cover.

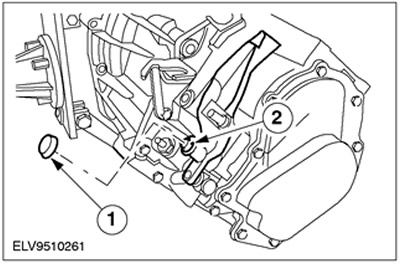

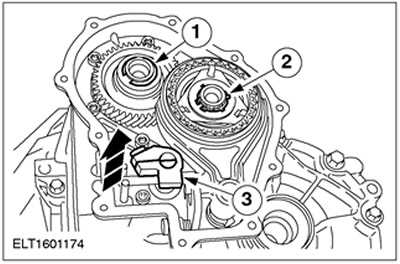

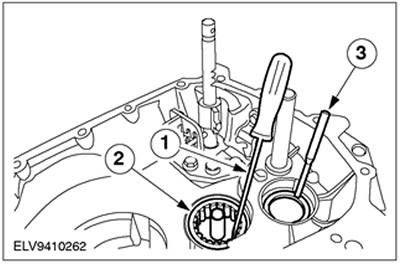

8. Remove the cover and gear selection locks.

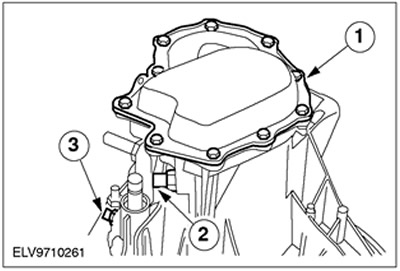

- 1. Lid

- 2. 5th gear select lock mechanism

- 3. Mechanism of blocking of a shaft of a choice of transfers.

9. Remove a lock ring and a finger of a choice of transfers.

- 1. Remove the retaining ring from the 5th gear and discard it as no longer needed.

- 2. Remove the retaining ring from the 5th gear synchronizer assembly and discard it as no longer needed.

- 3. Remove the pin and discard it as no longer needed.

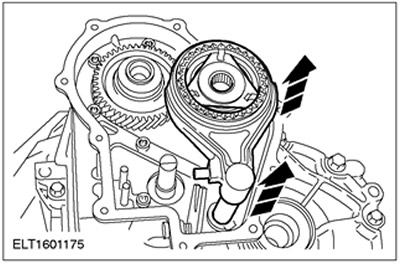

10. Remove the 5th gear synchronizer together with the gear selection fork.

11.

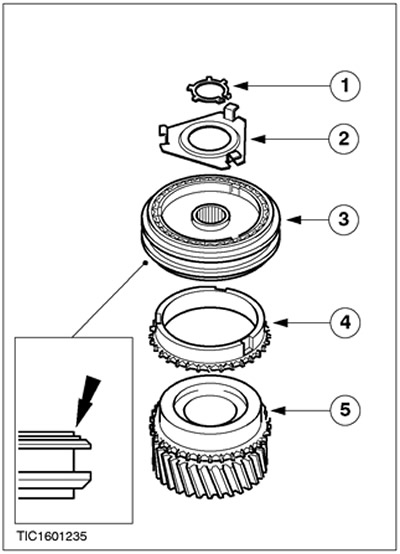

NOTE: Before disassembly, note the installation position of the synchronizer.

Disassemble the 5th gear synchronizer.

- 1. Retaining ring

- 2. Lock bar

- 3. Synchronizer

- 4. Synchronizer ring

- 5. 5th gear

12. Remove the 5th gear.

13.

CAUTION: Do not hit the mating surface directly.

Remove the 5th gear housing.

- 1. Remove the bolts and carefully separate the sections of the 5th gear housing by lightly tapping on them.

- 2. Clean the mating surface.

14.

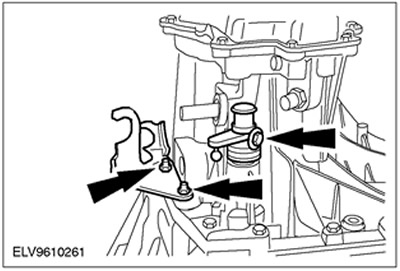

CAUTION: Do not hit the mating surface directly.

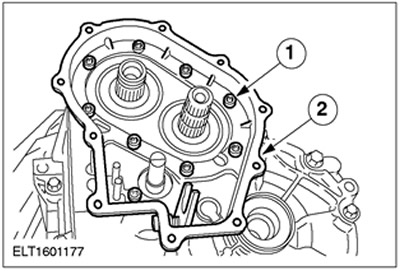

Remove retaining rings.

- 1. Remove seal and discard as no longer needed.

- 2. Remove the output shaft circlip and discard it as no longer needed.

- 3. Remove the input shaft snap ring and discard it as no longer needed.

- 4. Remove the process plug.

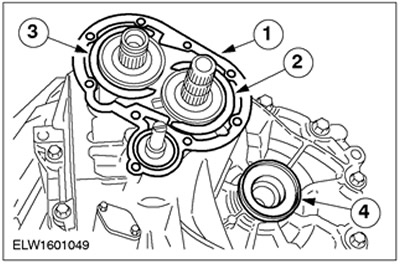

15. Remove both oil seals (left side shown).

- Using the special tool, remove the front axle oil seals.

- The reversing light switch should only be removed for sealing purposes.

16.

NOTE: Rotate the crankcase slightly to raise it (transmission vent pipe attached to input shaft).

Separate the sections of the gearbox housing.

- Remove the bolts and carefully separate the crankcase sections by lightly tapping on them.

- Clean the mating surface.

17. Remove the upper circlip from the gear selector rod guide.

- 1. Remove the top retaining ring and discard it as no longer needed.

- 2. Lower the selector rod guide bushing down.

18. Remove the selector rod guide bush.

- 1. Remove the lower retaining ring of the guide bushing and discard it as no longer needed.

- 2. Remove the selector rod guide bush.

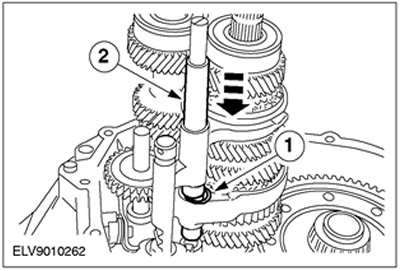

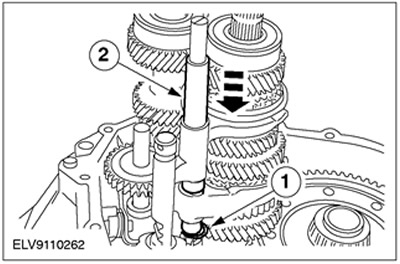

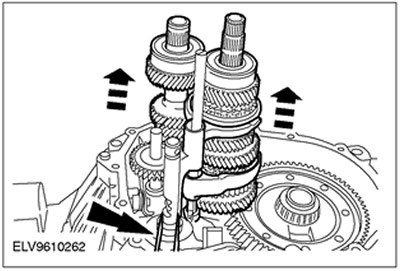

19.

NOTE: To facilitate disassembly, connect a rubber strap to the auxiliary select shaft.

Remove the primary and secondary shafts together with the gear selector forks.

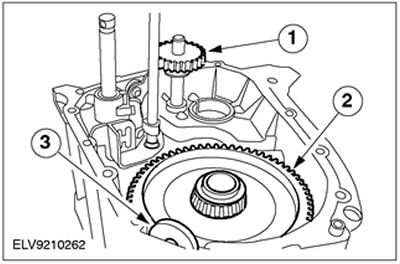

20. Remove the reverse idle gear, differential and permanent magnet.

- 1. Idler reverse gear

- 2. Differential

- 3. Permanent magnet

21. Remove the gear selection rod along with the locking bar.

- 1. Shift stop sleeve

- 2. 5th/reverse selector rod

22. Remove the secondary shaft roller bearing.

- 1. Remove the rollers from the cage.

- 2. Remove separator.

- 3. Remove the axle shaft oil seal.

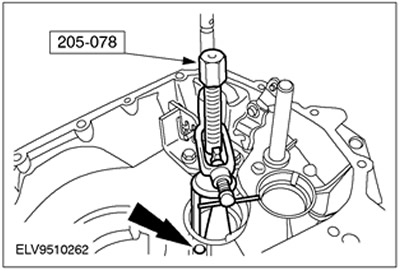

23.

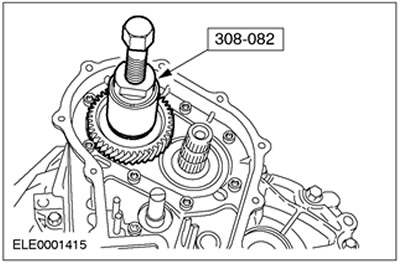

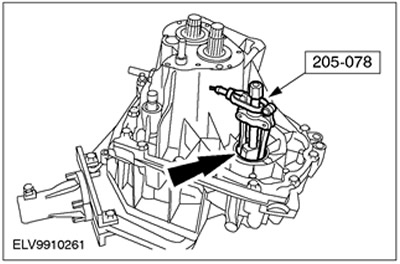

CAUTION: Use the special tool in the indicated position. Otherwise, the plug will be removed from the crankcase.

Remove the secondary shaft bearing inner race. Remove the oil nozzle.

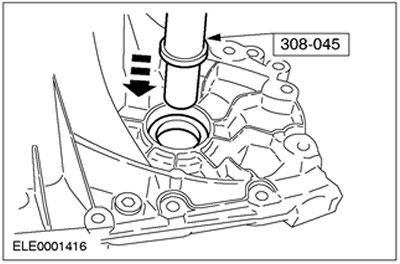

24.

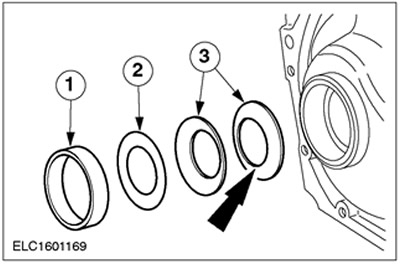

NOTE: Refer to step 25 for disk installation sequence.

Remove the bearing inner race.

25. The sequence of installation of differential discs.

- 1. Bearing inner ring

- 2. Shim

- 3. Cup washers

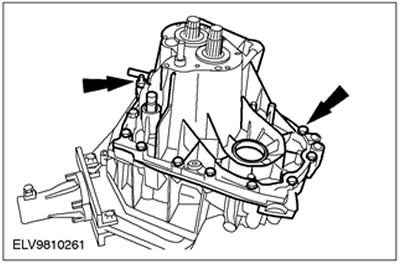

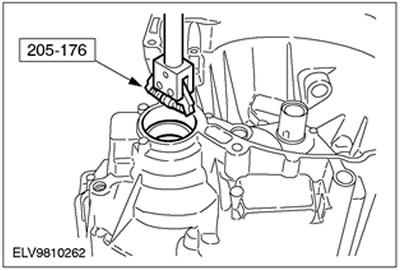

26.

NOTE: Install the special tool in the crankcase recess.

Remove the differential bearing inner race.

Visitor comments