Note: A new or remanufactured cylinder head can be purchased from manufacturers or remanufacturers. Please note that special tools will be required for disassembly and inspection, and new parts are not always easy to obtain. Thus, a more convenient and profitable option for you is to purchase a remanufactured head, rather than disassembling, inspecting and restoring a used head.

1. Remove camshafts and hydraulic lifters (chapter 2A or 2B). Carefully fold the expansion joints as described above (see fig. 7.1).

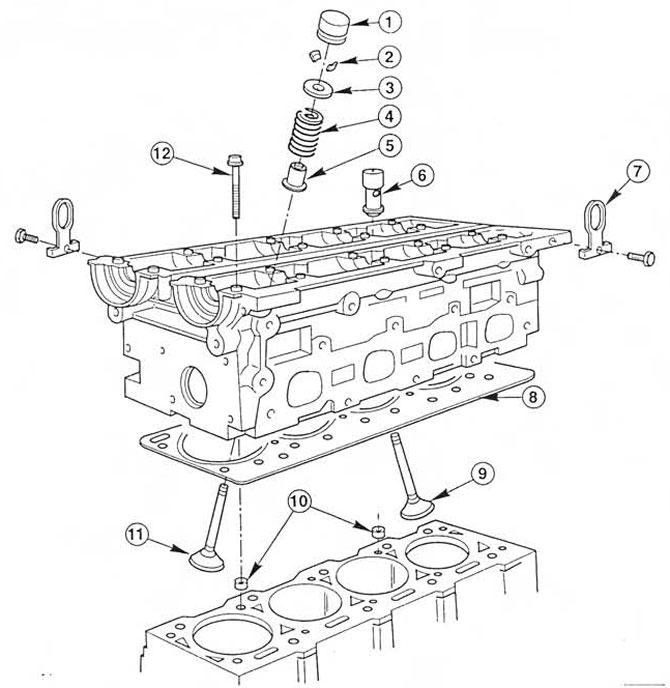

Pic. 7.1 Cylinder head components (4-cylinder engine, early production models)

Pic. 7.1 Cylinder head components (4-cylinder engine, early production models)

1. Hydraulic lifters

2. Valve cotters

3. Upper valve spring seat

4. Valve spring

5. Lower spring seat/valve stem seal

6. Lubrication valve

7. Engine load eye

8. Head gasket

9. Inlet valve

10. Locating pins

11. Exhaust valve

12. Block head bolt

2. Remove the head (-And) block (chapter 2A or 2B).

3. Using a compressor to compress the valve springs, compress the spring of each valve one by one so. so that you can take out the crackers. You will need a special compressor to compress the springs, which can be inserted deep into the head of the block without risking damage to the holes for the hydraulic lifters. These compressors are sold in auto supply stores. Release the compressor and remove the upper spring seat and the spring itself (see fig. 7.3, a-c).

4. If, after compression of the spring by the compressor, the upper seat of the spring does not move away and does not allow the crackers to be removed, lightly tap the top of the compressor with a light hammer so that the blow falls on the upper seat of the spring. After that, the saddle will move.

5. Pull the valve through the combustion chamber. If it gets stuck in the guide, drive it back in and deburr the cracker groove with a needle file or polishing stone. Be careful not to damage the hydraulic lifter hole.

6. Ford tool 21-160 is recommended to remove the lower valve spring seat/valve stem seal. If you do not have it, then you can use a homemade (see fig. 7.6, a, b). Get a stiff spring of the right size. Screw that spring (or fixture) into the cuff, and then pull the cuff out of the valve guide. It is almost impossible to remove the cuff without the help of a device, without risking damage to the block head.

7. Valves should be stored with the appropriate cotters, spring seats and springs so that they can be reinstalled when installed. To do this, use small plastic bags with tags (see fig. 7.7).

8. If you need to remove the valve of the lubrication system (for thorough flushing of the oil channels of the block head), consult your dealer about this. It is possible that the valve will have to be broken and then replaced with a new one. To do this, screw a self-tapping screw into the valve vent and pull out the valve. When assembling, the new valve must be pressed into place (see fig. 7.8).

Visitor comments