Withdrawal

1. Disconnect the negative battery cable. For better access, remove the battery and air cleaner.

2. Drain the liquid from the cooling system (Chapter 1).

3. Remove the upper and lower sections of the intake manifold (chapter 6).

4. Drain engine oil (Chapter 1).

5. Remove MGR chains (paragraph 5). Note: If only one of the head covers needs to be removed, remove only the corresponding chain.

6. Temporarily install the right engine mount and remove the hoist.

7. Remove camshafts, hydraulic lash adjusters and rocker arms (paragraph 12).

Rear block head

8. Remove the oxygen sensor from the exhaust manifold of the rear head of the block (chapter 4b). Remove the engine rear load eye bolt and exhaust pressure sensor and bracket (see fig. 13.8).

9. Disconnect the RVG system valve back pressure sensor hoses from the pipe connecting the RVG system valve to the exhaust manifold.

10. Disconnect the wiring from the back pressure sensor of the RVG system valve and the RVG unit.

11. Turn away a nut of the union and disconnect a pipe of the valve of system RVG from a final collector of a back head.

12. Release collars and disconnect hoses from a connecting pipe of the cooling system located from the left edge of heads of the block. Remove the pipe from the front head of the block and remove the O-ring.

14. Now you can remove the exhaust manifold of the rear head of the block. It can also be removed together with the rear head of the block, and then separated from it.

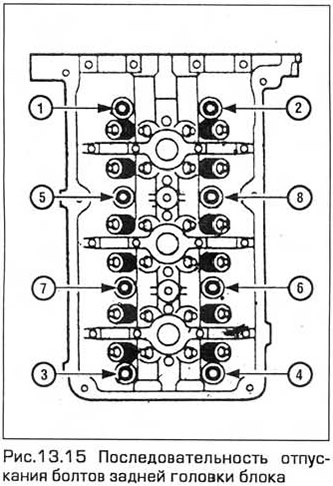

15. Consistently (see fig. 13.15) loosen the head bolts (one turn at a time). Remove them along with the spacers. After removal, it is always recommended to replace the bolts.

16. Remove the block head with an assistant (if possible), because it is heavy. Remove the gasket.

17. Turn out bolts of an inlet collector, remove it and remove a lining.

Front block head

18. Remove the coolant pump (chapter 3). If necessary, remove the thermostat housing and hoses (see fig.13.18,a,b).

19. Release the clamps and disconnect the hoses from the coolant connecting pipe on the left side of the block heads. Disconnect the wiring from the temperature sensors on this pipe (see fig.13.19).

20. Turn out bolts and remove a connecting pipe of a cooling liquid from a back head of the block. Remove the pipe from the front head of the block and remove the o-rings. (see fig. 13.20).

21. Release a collar and disconnect the bottom hose of a radiator from an elbow branch pipe of a forward head of the block. Then turn out bolts of a branch pipe.

22. Pull out the engine oil level dipstick.

23. Now you can remove the exhaust manifold of the front head of the block. It can also be removed together with the front head of the block, and then separated from it. If you will remove the block head together with the manifold, unscrew the air conditioning compressor bolts from the cylinder block and lean the compressor against the bulkhead of the engine compartment. Remove the oil filter as well. This will improve access when removing the exhaust pipe from the engine compartment.

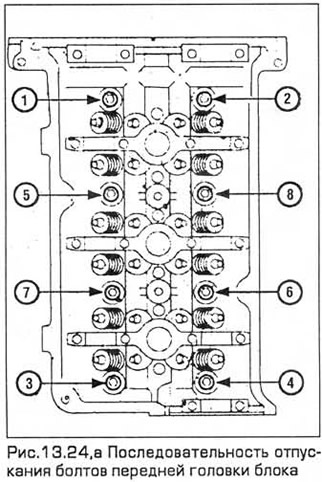

24. Consistently (see fig. 13.24, a) loosen the head bolts (one turn at a time). Remove them along with the gaskets (see fig. 13.24.6, in) After removal, it is always recommended to replace the bolts.

25. Remove the block head with an assistant (if possible), because it is heavy. Remove gasket (see fig. 13.25, a, b).

26. Turn out bolts of an inlet collector, remove it and remove a lining.

Installation

27. Before installation, it is necessary to ensure that the mating surfaces of the block head and cylinder block are perfectly clean. With a hard wooden or plastic scraper, remove the remnants of the old gasket, as well as traces of soot. Also clean the piston bottoms. Don't scratch the soft aluminum alloy head. Follow that. so that carbon deposits do not get into the oil or coolant channels. Use paper and tape to plug the oil, coolant, and bolt holes in the head of the block. Clean all pistons.

28. Check up interfaced surfaces of a head of the block and the block of cylinders on presence of dents, deep scratches and other traces of damages. Minor defects can be repaired with a file, but for significant damage, the damaged surface must be machined or the damaged component replaced.

29. If you suspect that the surface under the head gasket is warped, check it with the end of a metal ruler. If necessary, see Chap. 2B.

30. Clear interfaced surfaces of a head of the block and the block of cylinders. Make sure that the dowel pins are driven into the cylinder block and that the block head bolt holes are free of grease.

Front block head

31. Install a new gasket on the surface of the cylinder block (see fig.13.31).

32. Clean the mating surfaces of the exhaust manifold and block head. Then install the manifold with a new gasket and tighten the bolts (paragraph 7). You can install the manifold after installing the block head on the cylinder block.

33. Gently lower the head onto the cylinder block gasket, resting it on the dowel pins (see fig. 13.33).

34. Insert the block head bolts with washers and tighten them by hand.

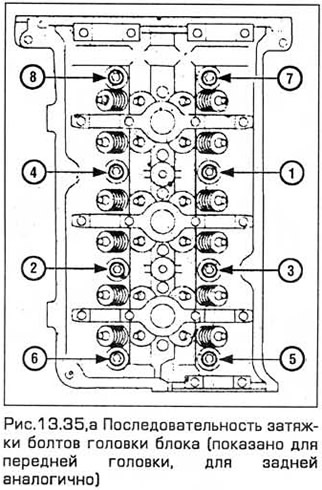

35. Torque wrench in series (see fig. 13.35, a, b) tighten the block head bolts in step 1.

36. Final tighten the bolts (see Technical Requirements). Use tools to turn the bolts to the required angle (see fig.13.36).

37. If necessary, install the exhaust manifold on a new gasket.

38. Insert the engine oil dipstick.

39. Install the elbow with a new gasket on the block head and tighten the bolts. Disconnect the lower radiator hose and tighten the clamp.

40. Install the coolant connecting pipe with new O-rings and new gasket and tighten the bolts. Install hoses and tighten clamps. Connect the wiring to the temperature sensors, and then install the coolant pump (chapter 3).

Rear block head

41. Note: If you were filming (during repair) bracket for the right support of the engines, then it must be installed before installing the rear head of the block, since it will not be possible to do it afterwards (see fig. 13.41).

42. Install a new gasket on the surface of the cylinder block (see fig.13.42).

43. Clean the mating surfaces of the exhaust manifold and block head. Then install the manifold with a new gasket and tighten the bolts (paragraph 7). You can install the manifold after installing the block head on the cylinder block.

44. Gently lower the head onto the cylinder block gasket, resting it on the dowel pins (see fig.13.44).

45. Insert the block head bolts with washers and tighten them by hand.

46. Torque wrench in series (see fig. 13.35 a) tighten the block head bolts in step 1.

47. Final tighten the bolts (see Technical Requirements). Use tools to turn the bolts to the required angle.

48. If necessary, install the exhaust manifold on a new gasket.

49. Install the coolant connecting pipe with new O-rings and a new gasket and tighten the bolts. Install hoses and tighten clamps. Attach wiring to temperature sensors.

50. Install the RVG valve pipe to the rear head exhaust manifold and tighten the union nut.

51. Connect the RVG system back pressure sensor wiring.

52. Attach the hoses of the RVG system back pressure sensor to the pipe connecting the RVG system valve to the exhaust manifold.

53. Install the oxygen sensor on the exhaust manifold (chapter 4b).

46. Torque wrench in series (see fig. 13.35, a) tighten the block head bolts in step 1.

47. Final tighten the bolts (see Technical Requirements). Use tools to turn the bolts to the required angle.

48. If necessary, install the exhaust manifold on a new gasket.

49. Install the coolant connecting pipe with new O-rings and a new gasket and tighten the bolts. Install hoses and tighten clamps. Attach wiring to temperature sensors.

Front and rear block heads

54. Install camshafts, hydraulic lifters and rocker arms (paragraph 12).

56. Hang the engine with a lift. Then remove its right support to install the MHR chains and their covers.

57. Install MGR chains and their covers (paragraph 10). Install the engine mount and remove the lift.

58. Install the upper and lower sections of the intake manifold (paragraph 6).

59. Install the battery and air cleaner if removed. Connect the negative battery cable (chapter 5, paragraph 1). Note: To restore the settings of the engine management system due to battery disconnection, a mileage of about 15 km is required. In this case, the engine may not work quite normally.

60. Refuel the engine with oil (Chapter 1).

61. Drink liquid into the cooling system (Chapter 1).

62. Start the engine and warm it up to normal operating temperature. Check connections for oil or coolant leaks.

Note: Engine operation may not be normal after disconnecting the battery.

Visitor comments