2. Supports can be removed and installed individually. If you need to disassemble several supports, such as when removing a power unit, then this removal and installation procedure must be performed in a clear sequence (chapter 2B).

Inspection

3. For access to the right support of the engine turn out screws of fastening of a reserve tank of system of cooling to the internal panel of the right forward fender. Move the tank to the side. To access the left engine mount, remove the battery (chapter 5A) and air cleaner (chapter 4A). To access the front and rear engine mounts, apply the parking brake, raise the front of the vehicle and place it on the stands. Use a mirror.

4. Inspect the supports for rubber cracks, hardening, or separation of the rubber from the metal backing. If any of these symptoms are found, replace the support.

5. Check the tightness of all nuts and bolts of the supports, if necessary using a torque wrench.

6. Check the possibility of relative displacement of the bracket of each support and the power unit or body. To do this, move the supports with a power screwdriver or pry bar. If mixing is noticeable, check tightness (torque wrench) support fasteners. If the play persists, then you need to find and replace worn components.

Replacement

Right support

7. Turn out bolts of a cover of a pulley of the pump of the cooling system on top of the engine.

8. Turn out screws and move a reserve tank of the cooling system aside.

9. Hang the engine with a lift. If you need to remove only the right support, then it is allowed to carefully support the engine with a jack through a wooden gasket placed under the pallet.

10. Mark the position of the support bracket. Loosen the nuts and remove the bracket. Note the position of the ground wire (see fig.20.10.a-c). Note: These nuts are self-locking and must be replaced.

11. Turn out bolts of a support from the body panel.

12. Establish a new support on the body panel and tighten bolts the demanded moment.

13. Install the bracket on the mount and motor in the position marked during removal. Tighten the new nuts to the required torque. Install the ground wire correctly.

14. Lower the vehicle and remove the lift.

15. Install the reserve tank and tighten its screws.

16. Install the water pump pulley cover on top of the engine. Screw in the bolts.

Left support

17. Remove the battery (chapter 5A).

18. Remove the air cleaner (chapter 4A).

19. Turn out bolts of a cover of a pulley of the pump of the cooling system on top of the engine.

20. Hang the transmission with a hoist. If you need to remove only the left support, then it is possible to carefully support the transmission with a jack through a wooden spacer.

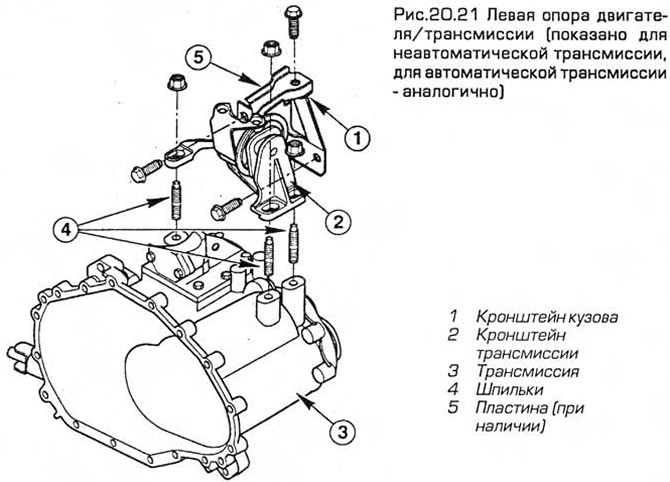

21. Mark the position of the support bracket. Remove the nuts from the transmission studs (see fig.20.21).

Note: These nuts are self-locking and must be replaced.

22. Turn out bolts of a support from the panel of a body (see fig.20.22).

23. Establish a new support on the body panel and tighten bolts the demanded moment.

24. Install the bracket on the support and transmission in the position marked during removal. Tighten the new nuts to the required torque.

25. Lower the vehicle and remove the lift.

26. Install the coolant pump pulley cover on top of the engine. Screw in the bolts.

27. Install the battery (chapter 5A) and air cleaner (chapter 4A).

28. Connect the negative battery cable (chapter 5, paragraph 1).

Note: To restore the settings of the engine management system due to battery disconnection, a mileage of about 16 km is required. In this case, the engine may not work normally.

Front support (roll limiter)

29. Apply the parking brake. Raise the front end and place it on stands.

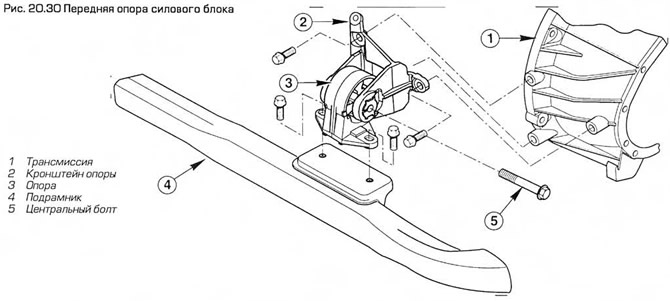

30. Turn out bolts of fastening of a forward support to a stretcher, attacks the central bolt. Remove support (see fig.20.30).

31. If necessary, remove the bracket bolts from the transmission and remove it.

32. Install the bracket on the transmission and tighten the bolts to the required torque.

33. Install the new front support on the bracket and insert its center bolt.

34. Screw in bolts of fastening of a forward support to a stretcher and tighten them the demanded moment.

35. Tighten the central bolt to the required torque.

36. Lower the car to the ground.

Rear support (roll limiter)

37. Apply the parking brake. Raise the front end and place it on stands.

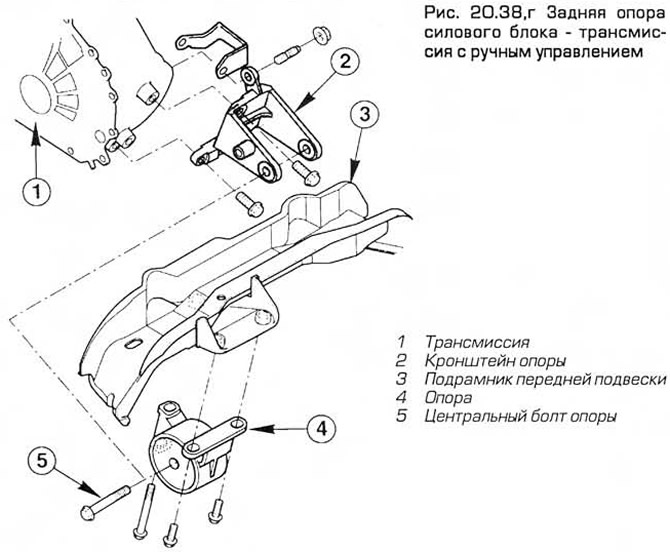

38. Turn out bolts/nuts of fastening of a back support, and also the central bolt. Remove support (see fig. 20.38, a-d). If necessary, jack up the transmission a little through the wood shim. Please note that on some models with automatic transmission, an additional rubber damper is installed under the subframe.

39. If necessary, unscrew the bracket bolts from the transmission and remove it (see fig.20.39).

40. Install the bracket on the transmission and tighten the bolts to the required torque.

41. Install a new rear support on the bracket and tighten the bolts / nuts to the required torque. On models with automatic transmission, install the additional rubber damper on the subframe bracket and tighten the nuts to the specified torque.

42. Insert the central bolt and tighten it to the required torque.

Visitor comments