See Warnings and Notes for paragraph 4.

Duratec engines

Withdrawal

Note: Ford dealers use a special tool to align the power unit with the subframe. Before removing the power block, mark the position of the engine mounts.

1. Park the vehicle on a level surface and apply the parking brake.

2. Disconnect and remove the battery (chapter 5A).

3. Insert pieces of wire into the top heatsink support to secure it in place after detaching from the bottom supports.

4. Turn out bolts and remove the top cover of the engine. Release the coolant hose from the clamp as well.

5. Raise the front (so that you can remove the power unit from under the car after removing it) and place it on stands. Remove both front wheels.

6. Remove the screws from under the car and remove the lower radiator cap.

7. Empty the cooling system (chapter 10).

8. Place a container under the transmission. Then remove the drain plug to drain the oil. Clean the plug and tighten it securely.

Warning: Drain the oil only when the engine is cold!

9. Disconnect the accelerator cable from the throttle body (chapter A). Move the rope to the side.

10. Disconnect the cruise control cable from the throttle body (chapter 12). Move the rope to the side.

11. Release the clamps and disconnect the hoses of the forced crankcase ventilation system on both sides of the air duct connecting the air cleaner and the throttle body.

12. Release the clamps and disconnect the air duct connecting the air cleaner and the throttle body.

13. Release the clamps and disconnect the vacuum hose from the RVG system valve on the left side of the rear block head.

14. Disconnect the wiring from the sensor located on top of the air mass meter. Disconnect the wiring from the intake air temperature sensor located on the rear air cleaner cover.

15. Remove the air cleaner (chapter 4A).

16. Release the clamps and disconnect the brake booster vacuum hose from the top section of the intake manifold.

17. Wrap a rag around the fuel system pressure relief valve. Then, remove the cap screws and use a screwdriver to press the center pin to relieve any residual pressure in the fuel system. Then install the cover.

18. Disconnect the fuel inlet and outlet pipes on the left side of the engine and move them to the side. Their quick couplings must be disassembled with a special tool (chapter 4A).

19. Release collars and disconnect hoses from a distributive pipe of a cooling liquid located from the left edge of heads of the block. Disconnect the top hose from the radiator and thermostat housing.

20. Remove the ground wire bolts from the transmission. Remove the bolt and disconnect the main wiring harness connector in the engine compartment on the left and release the wires from the battery support bracket.

21. On models with non-automatic transmission, disconnect the connecting rods or cables of the gear selector (chapter 7 A). Disconnect the hydraulic clutch line at the top of the transmission (chapter 6). To prevent leaks, pinch the hose directly below the brake fluid reservoir.

22. On automatic transmission models, remove the selector cable bracket bolts on the side of the transmission and disconnect the end of the cable from the lever (chapter 7B).

23. Disconnect the wiring from the starter (chapter 5A). Where necessary, remove the plastic cover to access the terminals.

24. Disconnect the two fan electrical connectors located on the radiator on the left and release the wiring harness.

25. In the right rear corner of the engine compartment, remove the reserve tank of the hydraulic steering system from its supports, move it to the side and set it without tilting it.

26. Turn out a bolt of grounding of conducting of the engine located on the internal panel of a wing at the left, behind a headlight. Disconnect the engine harness from the traction control module. On the latest models, rivets must be drilled to remove the cover. Remove the bolt and disconnect the electrical connector. To prevent dust or dirt from getting into it, wrap the electrical connector and the electronic control device with plastic wrap (see fig.5.26). Pull the wiring harness to the top of the engine.

27. Label the hoses. Then release the clamps and disconnect the three hoses from the reserve tank of the cooling system in the right front corner of the engine compartment. Remove the screws and remove the tank from the inner wing panel.

28. Disconnect the heater vacuum hoses at the rear of the engine.

29. On the rear head of the block on the left rear, disconnect the hose of the fuel evaporation control system from the throttle body.

30. Behind on the engine release conducting from fastenings and disconnect it from the oxygen gauge.

31. Remove the bolts and remove the exhaust fork section and rear catalytic converter from both exhaust manifolds and intermediate section (chapter 4A). Remove the pads.

32. Remove the lockers from under the wheel arches, having previously unscrewed their screws.

33. Remove both drive shafts (chapter 8). To do this, remove the clamp bolts and disconnect the ball joints of the lower arms from the steering knuckles. Tie down the suspension struts to prevent damage to the ball joint rubber boot.

34. Turn out bolts and remove the heat-insulating casing covering the steering mechanism.

35. Turn out bolts of the steering mechanism and tie it to the bulkhead of the engine compartment. Use a special key (chapter 10). If you do not have it, then the bolts can be removed after lowering the subframe (see below). Note that the steering gear remains connected to the bottom of the steering column.

36. Turn out nuts/bolts and the central bolt of a back support of the engine and remove it together with an arm. If necessary, use a jack or lift. Also unscrew the support bolts from the transmission.

37. Turn out bolts of fastening of a forward support to a stretcher, and also turn out the central bolt. Remove the support.

38. On models with an air conditioning system, remove the moisture separator bolts from the subframe on its left side. Slide the water separator to the side and tie it up without disconnecting the piping.

39. On the latest models, release the threaded fasteners of the short struts on both sides of the subframe.

40. On automatic transmission models, remove the transmission line bracket bolts from the front of the subframe.

41. Turn out bolts of an arm of the pipeline of a hydraulic system of a steering from a subframe on its right side.

42. Before removing the subframe, mark its position. Please note that Ford service centers use a special tool to align the subframe during installation.

43. Support the subframe with a jack through a wooden spacer. Remove the bolts, then carefully lower the subframe. If necessary, loosen the steering gear bolts when lowering the subframe. When the subframe is down, make sure the radiator is out of its lower rubber bushings and the bracket bolts can be removed from the subframe (see fig.5.43).

44. Disconnect the wiring from the vehicle speed sensor on the rear transmission.

45. On models with an air conditioning system, disconnect the wiring from the compressor and water separator and lay it on top of the engine.

46. Remove the accessory drive belt by turning the tensioner clockwise by its square end (on 3/8'), (see fig.5.46). Before removing, check the position of the lug in relation to the bracket stops. If the protrusion touches the right limiter, then the belt has stretched to the limit and needs to be replaced.

47. On models with an air conditioning system, remove the heat shield bolts from the compressor.

48. Release the clamp and remove the lower radiator hose.

49. Turn away a nut of the union and disconnect the pipeline of an oil radiator from a radiator. Get ready to fix the leaks.

50. On models with automatic transmission, unscrew the nuts of the fittings and disconnect the pipelines for forcing and draining the working fluid of the transmission radiator from the transmission. Plug the resulting holes. Then remove the drain pipe bolts from the transmission.

51. On models with an air conditioning system, remove the bolts securing the condenser to the radiator and tie the condenser to the cross member of the engine compartment. Remove the compressor bolts from the cylinder block and place it on the cross member of the engine compartment, and then tie it to it. Remove the bolts and remove the refrigerant pipe bracket from the coolant pipe. Do not disconnect refrigerant lines.

52. Pull out the pieces of wire inserted earlier to fix the radiator, then lower the radiator into the engine compartment, and then remove it from the car. If necessary, remove the upper rubber radiator mounts from the cross member. The radiator is installed tightly in the supports and must be removed carefully.

53. To improve access, before removing the radiator, remove the impellers of the electric fans and the casing (chapter 3).

54. Using a hoist, hang the power unit from the load eyes located at the front left and rear right.

55. Turn out bolts of the right support of the engine and remove the top bracket of a support. Turn out bolts and remove the bottom bracket of a support from the internal panel of the right wing.

56. Remove the bolt of the steering pump drive pulley (see fig.5.56). Hold the pulley with an oil filter wrench. Turn out bolts/nuts and remove the pump of a hydraulic system of a steering from an arm of the right support of the engine. Lean the pump with its pipelines against the bulkhead of the engine compartment and tie it to the wiper shaft.

57. Turn away nuts of fastening of an arm of the left support of the engine to transmission. If necessary, remove the bolts of this bracket from the inner fender panel.

58. Carefully lower the power block to the floor. Try not to touch the body parts and steering. If possible, lower the power pack onto a low cart that will make it easier to remove the power pack from under the vehicle.

Separation

59. Turn out bolts of an arm of a starter and remove it. Then remove the starter bolts from the transmission case.

60. Disconnect and release the wiring of the following components:

- A) speed sensor

- b) Control socket (automatic transmissions)

- V) Engine Coolant Temperature Sensor

- G) Transmission mode sensor (automatic transmissions)

61. On models with automatic transmission, remove the plastic cover and unscrew the nuts securing the torque converter to the faceplate. In this case, to access the nuts, you will need to turn the engine.

62. Turn out bolts of fastening of transmission to the engine. Some of them are located on the right side of the transmission.

63. Together with an assistant, carefully separate the transmission from the engine (see fig.5.63). On models with non-automatic transmission, ensure that the weight of the transmission does not load the clutch disc. On models with automatic transmission, ensure that the torque converter is connected to the pump on the transmission output shaft.

Installation

64. Verify that the adapter plate is installed on the dowel pins.

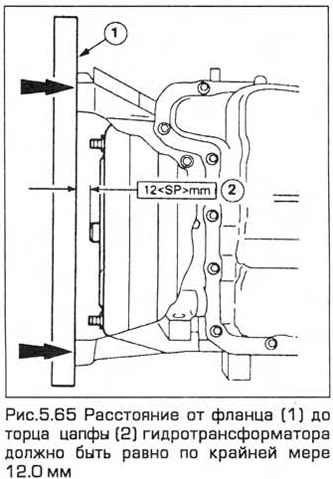

65. On automatic transmission models, make sure the torque converter is fully connected to the pump on the transmission output shaft. To check this with a ruler, measure the distance from the flange to the end face of the torque converter trunnion. It must be at least 12.0 mm (see fig.5.65), set the transmission selector to position "D". Lubricate the pin with refractory grease.

66. Together with an assistant, carefully connect the transmission to the engine. On automatic transmission models, the dowel pins must fit into the faceplate holes.

67. Insert the bolts into the transmission flange and tighten them to the required torque.

68. On models with automatic transmission, turning the engine, tighten the torque converter nuts to the required torque.

69. Perform the remaining installation procedures in the reverse order of removal, taking into account the following:

- A) When installing the subframe, Ford tool 15-097A will be required to align its position before tightening the bolts (see fig. 5.69). If you do not have such a device, set the subframe according to the marks.

- b) Establish support of the engine on marks made before removal. The device in the form of a front engine mount is used to align the engine with the subframe when installing the rest of its mounts. This tool must be installed on the subframe instead of the front engine mount. so that the arrow on it points forward. If you do not have such a device, install the supports according to the marks.

- V) Torque tighten all bolts and nuts

- G) Eliminate air from the clutch hydraulic system (chapter 6)

- d) Adjust the accelerator cable (chapter 4A) and speed control cable (chapter 12)

- e) Refill and bleed the cooling system (Chapter 1)

Visitor comments