Warning: Gasoline is highly flammable. Use extreme caution when working on the fuel system. Work in a well ventilated area - open all windows and doors to create an exhaust hood. Do not smoke or allow naked flames or incandescent lamps without protective covers near the work area. Please note that the fuel used in household appliances (heaters, boilers, dehumidifiers), also poses a risk. Keep this in mind when working near such equipment. Near the working area, it is always necessary to have a fire extinguisher suitable for extinguishing burning oil products, and before starting work, you must read the instructions for its use. If fuel comes in contact with skin, wash immediately with soap and water. Please note that fuel vapors are just as dangerous as liquid fuels.

Note: Please read this entire paragraph as well as the previous paragraph before performing this procedure. The engine and transmission must be removed as a unit, lowering it to the ground and removing it from under the car, and then the engine and transmission must be separated.

4 cylinder engines (release models before 05.1998)

Withdrawal

1. Place the vehicle on a firm level ground, apply the parking brake. Loosen the front wheel nuts.

2. Eliminate residual pressure in the fuel system (chapter 4).

3. Disconnect the negative battery cable (chapter 5, paragraph 1). Battery can be removed for better access (chapter 5).

4. Cover the wings and the front cross member of the engine compartment, and then remove the hood (chapter 11).

5. In any case, when you disconnect vacuum hoses, coolant hoses, ventilation hoses, electrical wire connectors, earth wires, fuel lines, which is provided for by the following procedure, mark the detached elements with labels so that they can be fixed in place during installation.

6. Disconnect the two electrical wiring connectors, disconnect the vacuum hose (in the presence of), disconnect the crankcase breather hose from the head cover. Remove the air cleaner assembly along with the air mass meter, resonator and prechamber (chapter 4).

7. Equalize the pressure in the fuel tank with atmospheric pressure by removing the tank cap. Then unfasten the inlet and outlet fuel lines attached to the chassis (chapter 4A) and plug or cover any openings (see fig. 4.7).

8. Disconnect the accelerator cable from the throttle linkage (chapter 4A). Disconnect also the speed control cable (if available) (chapter 12). Fix the rope (s) away from the engine/transmission.

9. Release the wire clamp and disconnect the electrical connector of the wires of the steering hydraulic pressure switch. Remove the steering pressure pipe bolts and ground bolt from the engine load lug/rear head base plate (see fig. 4.9, a-c).

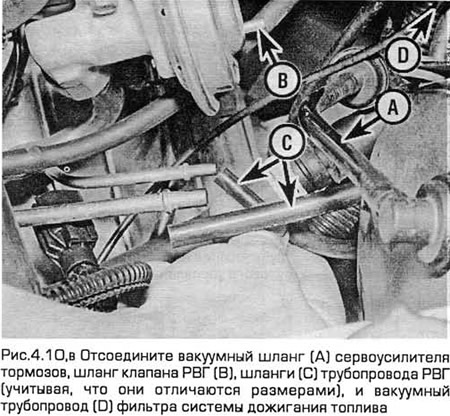

10. When marking, disconnect the vacuum hoses in the following sequence:

- A) One is from the rear of the throttle body. (Disconnect only one hose. The second hose going to the fuel pressure regulator does not need to be disconnected.) (see fig. 4.10,a).

- b) One - from the fitting on the left edge of the intake manifold (see fig. 4.10.6).

- V) Vacuum hose for brake booster (chapter 9).

- G) Disconnect all vacuum hoses from the EGR system components - one from the EGR valve and two from the EGR pipeline. Please note that the last two hoses differ in the size of the nozzles and therefore cannot be confused.

- d) The vacuum line coming from the afterburner filter housing and passing over the transmission must be disconnected. To do this, pull out the plastic pipe from the rubber hose located under the solenoid valve of the fuel afterburning system installed on the bulkhead of the engine compartment (see fig.4.10,c).

- e) Secure all of these hoses so that they are not damaged when removing the power unit.

11. Turn out a bolt of connection of the power block with a mass wire. This bolt is located on top of the transmission (see fig. 4.11). Disconnect the speedometer cable (chapter 12) and fix it away from the power box.

12. On manual transmission models, disconnect the clutch cable (chapter 6). On models with automatic transmission, disconnect the selector cable (chapter 7B) and fix it away from the power box.

13. Marking all detachable components, disconnect the engine wiring harness from the body as follows:

- A) Starting at the left side of the engine compartment, unplug the three large electrical connectors attached to the suspension mount. (Please note that some connectors are secured with wire retainers (see fig. 4.13.a).

- b) Disconnect and/or disconnect the wiring from the battery to the starter by disconnecting one electrical connector.

- V) Disconnect the wiring connectors to disconnect the engine speed sensor, oxygen sensor and (in the presence of) oil level sensor wiring. Release the connectors from the retainers where necessary to free the wiring.

- G) Disconnect the wiring harness from the clamps and disconnect various components from it (disconnecting connectors), installed on the partition. Work in the engine compartment in the direction from left to right along the entire length of the harness (see fig. 4.13.6).

- d) Carefully pull the steering fluid reservoir up from its clips securing the reservoir to the suspension mount. Then unscrew the fixing bolt of the electrical connector of the electronic control device and pull out the plug of this connector (see fig. 4.13, in).

- e) Turn out a bolt of a mass wire from the internal panel of the right wing. Release the engine wiring harness and install the steering fluid reservoir.

- and) Fix the engine wiring harness so as not to damage it when removing the power unit from the vehicle.

14. Turn out bolts of both parts of a heat-insulating casing of a final collector. Detach the coolant hose to remove the top cover.

15. Remove the accessory drive belt (Chapter 1).

16. Turn out bolts of the pump of a hydrosystem of a steering (chapter 10). Fix it as far as possible from the power block without disconnecting the hoses.

17. Raise the car and place it on supports. Then remove the front wheels. Drain the cooling system and (if you disassemble the engine) drain the engine oil and remove the oil filter (Chapter 1). Drain the transmission fluid as well (chapter 7).

18. Pull out the bottom part of the heat-insulating casing of a final collector.

19. Turn away nuts for a detachment of a reception pipe of an exhaust system from a collector. Then get the whole system out of its rubber mounts and pull it out from under the car (chapter 4A).

20. On manual transmission models, mark the position of the shift lever and transmission support rods on the rear of the transmission. Loosen the fixing nuts and remove the linkage heat shield from the bottom. Unbolt the rear end of the linkage to the bottom, slide the linkage back and tie it to the bottom (chapter 7A).

21. Disconnect both connecting links of the stabilizer of transverse vibrations from the corresponding suspension struts, and the ends of the transverse steering rods from the steering knuckles. Notice the brake hose bracket attached to each link stud. Loosen the clamp bolt securing the ball joint of each lower front suspension arm to the steering knuckle (chapter 10). Make sure both ball joints can be released from the steering knuckles if required and leave them in place with clamp bolts if necessary.

22. On models with an air conditioning system, remove the accumulator/drier bolts from the subframe. Fix this assembly as far as possible from the power block without disconnecting the system hoses.

Warning: Do not disconnect refrigerant hoses.

23. Turn out bolts of the steering mechanism from a stretcher. If the bolts are not accessible from above, then you will need a Ford tool to get to them from under the car (chapter 10).

24. Turn out two bolts of fastening of the pipeline of a hydraulic system of a steering to the right side of a stretcher.

25. Lock the radiator in working position. To do this, insert cotter pins through the holes in the rear of the front cross member of the engine compartment into the elements of the upper radiator supports. Remove the radiator support bracket bolts from the subframe. Please note that they differ in shape, like mirror images, and are marked for correct installation (see fig. 4.25, a, b). Assemble the bottom support rubber pieces, considering which side they are on, and fold them for storage.

26. Turn out bolts of a back support of the power block from a stretcher. On models with automatic transmission, a separate damper can be installed under the subframe, the bolts of which must be unscrewed to access the support fasteners. On manual transmission models, also remove the center mount bolt and remove the mount bracket bolts from the transmission.

27. Turn out the central bolt of a forward support of the power block and turn out bolts of a support from a stretcher, taking into account position of an arm of an electric socket of conducting.

28. White paint or similar (but without scratching the surface) mark the subframe and the bottom for subsequent correct installation. Remove the four support bolts from the subframe (note that they have washers of different sizes, see fig. 4.47A) and release the subframe so that it hangs on the ball joints of the lower suspension arms. Disconnect ball joints (one at a time) from knuckle nodes (chapter 10) and lower the subframe to the ground. Pull it out from under the car.

29. Marking all detachable components (see point 5) and preventing leakage of coolant, disconnect the hoses and pipes of the cooling system as follows (see chapter 3 for details):

- A) Remove the upper radiator hose.

- b) Remove the hose (heater), going from the thermostat to the fitting located on the partition of the engine compartment.

- V) Disconnect the hose going to the reserve tank from the thermostat. Secure this hose away from the work area.

- G) Disconnect the hose/pipe that goes to the lower radiator hose from the thermostat.

- d) Disconnect the lower radiator hose from the radiator fitting, from the heater coolant pipe and from the coolant pump fitting. Secure this hose away from the work area.

- e) Turn out bolts of the pipeline of a cooling liquid (heater) from the pallet. Disconnect from pipeline/hose (along its route to the fitting located on the partition of the engine compartment) , hoses from oil cooler fittings (in the presence of), and then remove the coolant pipe.

- and) On models without an air conditioning system, secure the radiator by moving it as far forward as possible from its operating position. On models with an air conditioning system, remove the radiator assembly (chapter 3).

30. On models with an air conditioning system, disconnect the compressor wiring connector and remove the compressor bolts from the engine (see fig. 4.30). Fix the compressor as far as possible from the power unit without disconnecting the system hoses.

Warning: Do not disconnect refrigerant hoses.

31. On models with a manual transmission, disconnect the drive shafts from the transmission as follows (see chapter 8 for details):

- A) Turn away nuts of fastening of the bearing of a support of the right input shaft and remove a heat-insulating shield.

- b) Pull the right drive shaft out of the transmission. Get ready to fix the leaks.

- V) Lock the drive shaft away from the power unit. Remember that the assembly will need to be lowered out of the vehicle and note that the inner joint must not be rotated more than 18°.

- G) Pull the left drive shaft out of the transmission. Get ready to fix the leaks. Lock the shaft away from the transmission and ensure that the inner pivot does not rotate more than 18°.

32. On models with automatic transmission, follow these instructions (if necessary, see chapter 7B and 8):

- A) Remove the center bolt and then remove the power unit rear support bracket bolts from the transmission.

- b) Disconnect the transmission radiator line from the rear of the transmission and secure it away from the transmission.

- V) Pull the left drive shaft out of the transmission. Get ready to fix the leaks.

- G) Lock the drive shaft away from the power unit. Remember that the assembly will need to be lowered out of the vehicle and note that the inner joint must not be rotated more than 18°.

- A) Turn away nuts of fastening of the bearing of a support of the right input shaft and remove a heat-insulating shield.

- e) Pull the right drive shaft out of the transmission. Get ready to fix the leaks. Lock the shaft away from the transmission and ensure that the inner pivot does not rotate more than 18°.

- and) Disconnect the transmission radiator line from the front of the transmission and secure the line away from the transmission.

33. Now the power block rests only on the left and right supports along with all the components that normally connect it to other vehicle systems and which are now disconnected or removed and fixed away from the power block. Check again and make sure everything is done correctly. Then make sure that the body is securely supported, sufficient to perform the operation of extracting the power unit through the bottom.

34. Hang the power block on the lugs located on the head of the block. Turn out six nuts of fastening of an arm of the right support, and then three nuts of fastening of an arm of the left support.

Warning: If the vehicle or power unit is supported only by a jack or other lifting device, do not work under the power unit or vehicle!

35. Lower the power block to the ground and pull it out from under the car (see fig. 4.35).

Separation

36. Separate the transmission from the engine, taking into account the instructions in chapter 7.

37. After removing the power unit, check its supports and replace them if damaged or worn. Also check the condition of all coolant hoses as well as vacuum hoses and lines (Chapter 1). All components that are normally hidden can now be carefully inspected and replaced if found to be faulty. On models with a manual transmission, it makes sense to disassemble the clutch components (chapter 6). When performing an overhaul of the engine, it makes sense to replace the entire clutch assembly. Check the status of all components (such as transmission sleeves), that were dislodged when removed, and replace any that are damaged or worn.

Installation

38. Installation - in the reverse order of removal, taking into account the following. Tighten all fasteners to the required torque. If in the Technical requirements of the chapters 2A and 2B torque requirement for any connection is not specified, refer to the Specifications in the relevant chapter of this book.

39. In addition to the instructions in #37, always replace any o-rings and self-locking nuts removed during removal.

40. If the wiring is fixed with ties that need to be untied when removed, then new ties must be prepared for installation.

41. After completing the repair, install the transmission on the engine (chapter 7).

42. Move the power unit under the car, connect it to the lifting device and lift the unit to the installation site so that the right and left supports of the unit can be restored. Then lightly tighten the nuts. Keep the power block supported by the lifting device. Its weight should not be transferred to the supports until they are all properly installed.

43. Install drive shafts (chapter 8) using new elastic rings, as well as preventing the rotation of the internal hinges at an angle greater than the maximum. On models with manual transmission, perform this procedure in the reverse order of step 31. On models with automatic transmission, follow these instructions (chapter 7B and 8):

- A) Install the left drive shaft.

- b) Attach the transmission radiator lines first to the rear and then to the front side, fastening the clamps accordingly and tightening the couplings to the required torque.

- V) Install the right drive shaft to the transmission. Install the heat shield. Tighten the support bearing nuts to the required torque.

- G) Install the power unit rear support bracket to the transmission. Torque tighten the bolts, then install the support and lightly tighten the center bolt.

44. On models with an air conditioning system, do not forget to install a compressor. Tighten the bolts to the required torque and connect its electrical connector.

45. Given the observations and marks made during removal, install the cooling system hoses. Where they have been disconnected or released from their latches, be sure to secure them at the appropriate time in the installation procedure. Install the radiator (if it was taken) and fix it with cotter pins in working position.

46. Bring the stretcher (each side in turn) and connect it with the ball joints of the lower suspension arms to the steering knuckles. Install the subframe bolts, making sure the washers are installed correctly, and lightly tighten the bolts.

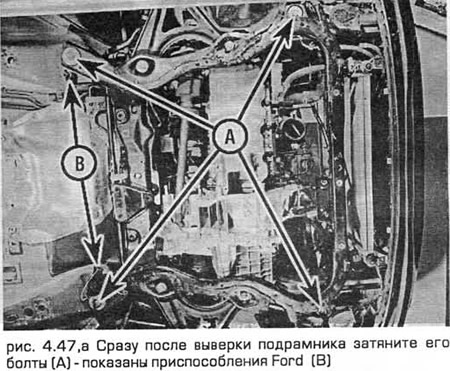

47. Now the subframe must be placed on the body. For this, the Ford 15-097 fixture is intended, which is a pair of conical guides with places for fixing them to the subframe during its installation. But in view of the fact that the working diameter of such devices is 20.4 mm, and the corresponding holes in the subframe and body are 21 and 22 mm, respectively, when aligning the subframe, a significant gap is possible even when using regulated devices. If you do not have them, then the subframe can be exposed by eye, centering its hole relative to the body and using the marks made during removal. Another way to align the subframe is to use a tapered rod (such as a clutch centering tool) or even a high key head (right size) (see fig. 4.47, a, b).

48. Immediately after alignment of the subframe, tighten its bolts to the required torque, do not mix it. After tightening the bolts, immediately repeat the check of the position of the subframe.

49. After alignment and secure fastening of the subframe, it is necessary to accurately set the power unit for the subsequent assembly of its supports. For this, the Ford 21-172 fixture is intended. This device is bolted to the subframe instead of the power unit front support so that when the central support bolt is installed, it is held in position: 60 mm above the upper surface of the subframe with an offset of 20 mm back relative to the axes of the subframe support bolt holes. If you do not have such a device, then to perform this operation, you must make a copy of it (see fig. 4.49).

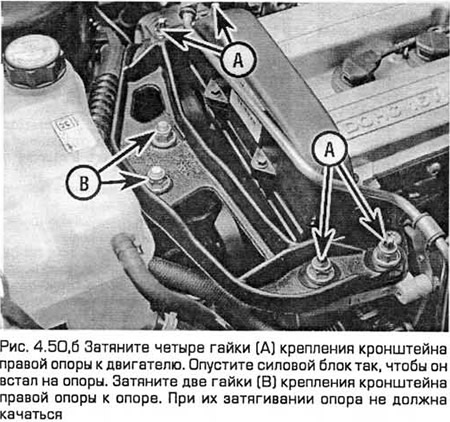

50. Attach the fixture to the subframe in place of the power unit front support and lightly tighten the center bolt. Install the power block supports in the following sequence:

- A) Tighten nuts of the left support the demanded moment. When tightening them, the support should not swing (see fig. 4.50 a).

- b) Tighten the four nuts securing the right support bracket to the engine to the required torque.

- V) Using the lifting gear, slowly lower the power unit until it rests on its supports.

- G) Tighten the two nuts securing the right support bracket to the support to the required torque. When tightening them, the support should not swing (see fig. 4.50.6).

- d) Assemble the rear support of the power block and tighten the fasteners to the required torque. Finally, tighten the center bolt.

- e) Install the steering gear to the subframe. If you are using a Ford underbody bolt tightener (chapter 10), please note that you will need a torque wrench that can be used to tighten counterclockwise.

- and) Remove the special tool bolts from the front support. Then install the front support. Don't forget the wiring harness bracket. Torque tighten first the support bolts/nuts and then the central bolt (see fig. 4.50, c, d).

51. Install the lower rubber supports under the radiator with the corresponding side. Then install the radiator support brackets on the subframe (to the required position - by marks). Tighten the bolts to the required torque. Remove cotter pins and secure coolant hose connections (if necessary).

52. Install the air conditioning battery/drier (if available) on the stretcher.

53. Tighten two bolts of fastening of pipelines of a hydraulic system of a steering located on the right side of a subframe.

54. Attach the ball joint of each lower front suspension arm, as well as each end of the tie rod to the corresponding steering knuckle, and both connecting links of the stabilizer bar to the respective suspension struts. Notice the brake hose bracket attached to each link stud (chapter 10).

55. On manual transmission models, move the linkage forward, tighten its rear fasteners, and then install the linkage heat shield. Connect linkage (gear shift) with the transmission support rods and adjust the linkage to the marks made during removal (chapter 7A).

56. Install the remaining components and fasteners in the reverse order of removal.

57. Top up the engine with coolant and oil, and the transmission with working fluid (Chapter 1).

58. Start the engine and check if it runs reliably and for leaks. Stop engine and recheck fluid levels.

59. Remember that if the front suspension subframe and steering gear have been removed and installed, then it is necessary to check the alignment of the wheels and steering as soon as possible and make any necessary adjustments. This job is best left to the experts (dealers).

4 cylinder engines (release models from 05.1998)

Note: This procedure is for manual transmission models. For models with automatic transmission, the procedure is the same as for models produced before 05.1998.

Withdrawal

60. Remove the battery. (chapter 5A). Set transmission to neutral (manual transmission) or in position "R" (automatic transmission).

61. Remove the hood (chapter 11).

62. Alternately unscrew the nuts of the upper supports of both front suspension struts (loosening the nut about 5 turns at a time and holding the damper rod with a wrench).

63. Apply the parking brake. Raise the front end and place it on stands. Remove both front wheels.

64. Remove the lower radiator cap. Drain the liquid from the cooling system.

65. Disconnect the wiring from the mass air flow meter and air temperature sensor.

66. Remove the air cleaner assembly (chapter 4A), then remove the air intake plenum.

67. Disconnect battery wiring (including ground wire) from the battery tray.

68. In the right front corner of the engine compartment, unscrew the bolts of the wire connection box and move it to the side.

69. Remove the bolts and remove the battery tray, taking into account the position of the wires.

70. In the right rear corner of the engine compartment, remove the reserve tank of the hydraulic steering system from its support and move it to the side. Remove the traction control module wire bracket bolts. Disconnect the two ground wires, then disconnect the wiring connector of this module.

71. Disconnect the ground wire from the engine load lug.

72. Disconnect the steering hydraulic pressure sensor wiring and release the wiring from its mountings on the pipe.

73. In the engine compartment on the left, disconnect the main engine wiring connector, and also disconnect the ground wire. Release wiring from connections.

74. On models with cruise control, disconnect its wiring from the throttle body. Then disconnect and remove the cable of this device. See chapter 12 if necessary.

75. Disconnect and remove the accelerator cable from the throttle body. See chapter 4A if necessary.

76. Disconnect the vacuum hoses from the intake manifold and remember their position.

77. Pull out the dipstick at the front of the engine. Then turn out bolts and remove the heat-insulating casing of a final collector. Remove the coolant pipe bracket at the same time.

78. Remove the coolant pipe and disconnect the hose from the coolant pipe and the cooling system pump.

79. Remove the nuts securing the catalytic converter to the exhaust manifold and move the converter to the side.

80. On models with an air conditioning system, disconnect the compressor wiring on the right side of the engine.

81. Disconnect the wiring from the coolant temperature sensor near the engine lifting eye.

82. At the front of the engine, release the wiring from the front cross member of the engine compartment.

83. Release the clamps and remove the hoses from the radiator and thermostat housing.

84. Disconnect the wiring from the electric fan.

85. Disconnect the hoses from the reserve tank in the right front corner of the engine compartment.

86. Turn out bolts and remove the top cover of a belt drive located on the engine on the right.

87. Place a container under the clutch hydraulic power cylinder. Then release the clamp and disconnect the pipe (if necessary, see chapter 6). Remove the tube from the transmission and tie it aside.

88. Disconnect the transmission ground wire.

89. Turn out bolts and remove poker of the right forward wheel.

90. Turn the accessory drive belt tensioner clockwise and remove the belt.

91. Release the quick coupling and disconnect the vacuum brake booster pipe from the intake manifold.

92. Locate the oxygen sensor wiring connector on the side of the bulkhead at the bottom and disconnect it. Release wiring from connections.

93. Turn out bolts of fastening of a flange of forward section of an exhaust system to intermediate section. Remove the pipe from the rubber supports and remove it, as well as the gasket.

94. Turn out bolts of clips of spherical hinges of the lower arms of a forward suspension bracket and pull out the lower arms from naves. If necessary, see chapter 10. Also remove the ABS wiring brackets from the suspension struts. Be careful not to damage the rubber boots of the ball joints and the ABS sensor disk.

95. Remove both drive shafts (chapter 8).

96. Turn out bolts and remove a back support of the engine. Remove the support bracket from the transmission.

97. Slightly raise the transmission with a jack, then remove the nuts and center bolt of the front engine mount. Remove the support.

98. Remove the clamp bolt and remove the catalytic converter.

99. On models with air conditioning, disconnect the water separator, move it to the side and tie it.

100. Release the clamps and disconnect the lower coolant hoses.

101. Release the clamp and disconnect the heater hose from the engine bulkhead.

102. On models with an air conditioning system, remove the compressor bolts, move it to the side without disconnecting the pipelines, and tie it.

103. Disconnect the shift linkage cable from the lever on the transmission. Rotate the bracket counterclockwise to pre-tension, then remove the cable. Disconnect the other cable from the lever on the transmission. Rotate the other bracket counterclockwise to pre-tension, then remove the cable. Push the adjuster inward to release it.

104. Eliminate the residual pressure of the fuel system (chapter 4A).

105. Disconnect the fuel inlet and outlet hoses.

106. Turn out bolts of a reserve tank of system of cooling and move a tank aside. Disconnect the cruise control cable from the reservoir (in the presence of).

107. Hang the power block on the lift.

108. Mark position of the right support of the engine. Turn away nuts of a support, and release bolts only on two turns.

109. Mark the position of the left engine mount. Turn away nuts and bolts of a support.

110. Together with an assistant, carefully lift the power unit so that the steering hydraulic pump becomes visible. Remove the pump bolts from the engine, move the pump to the side and tie it down.

111. Carefully remove the power block from the engine compartment so as not to damage adjacent components.

Separation

112. Disconnect the wiring from the reverse indicator and engine speed sensor.

113. Disconnect wiring from starter main terminal and solenoid terminal.

114. Turn out the top bolts of fastening of a starter and the top bolts of fastening of the engine to transmission.

115. Remove the ground wire bolt from the transmission.

116. Turn out the lower bolt and remove a starter. Remove wiring.

117. Turn out other bolts of fastening of transmission to the engine.

118. Together with an assistant, separate the transmission from the engine without warping it so that the input shaft comes out of the clutch assembly.

Installation

119. On automatic transmission models, make sure the torque converter is fully connected to the pump on the transmission output shaft. To do this, use a ruler to measure the distance from the flange to the trunnion on the torque converter. It must be at least 12 mm. Move the transmission selector to position "D". Lubricate the pin with refractory grease.

120. Together with an assistant, connect the transmission to the engine so that the studs enter the holes in the faceplate. On models with automatic transmission, align the torque converter with the faceplate.

121. Insert bolts and sequentially tighten them to the required torque.

122. On models with automatic transmission, rotate the engine as needed and tighten the torque converter nuts to the required torque.

123. Follow the rest of the procedures in the reverse order of removal, considering the following:

- A) Install the engine mounts in the same position as before removal.

- b) Tighten all nuts and bolts to the specified torque.

- V) Bleed air from clutch hydraulic system (chapter 6).

- G) Adjust the accelerator cable (chapter 4A) and speed control cable (chapter 15).

- d) Fill the cooling system (Chapter 1).

Visitor comments