Every 16,000 km or 12 months.

General information

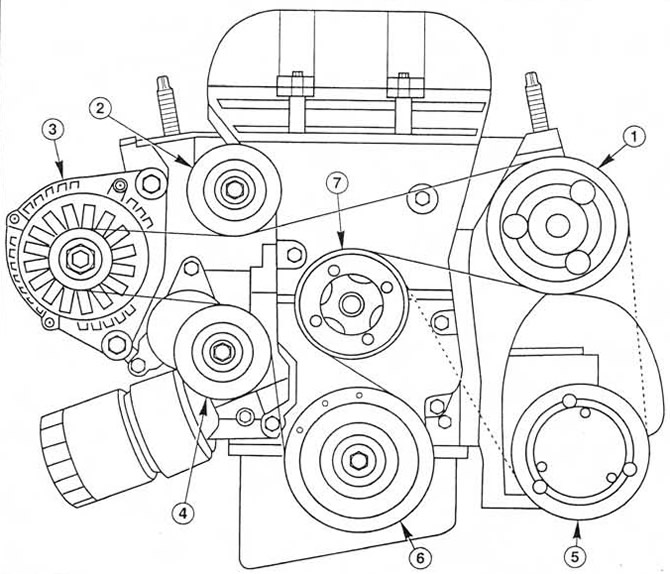

1. Auxiliary drive belt - flat, multi-ribbed, with a wedge-shaped section of the streams is located on the right side of the engine. It drives the generator, the cooling system pump (on 4-cylinder engines), hydraulic steering pump and (depending on performance) air conditioning compressor. The belt itself is driven by the crankshaft pulley (see fig. 5.1. a,b).

Pic. 5.1, a Route of the auxiliary drive belt - models manufactured before June 1998 with 4-cylinder engines.

Pic. 5.1, a Route of the auxiliary drive belt - models manufactured before June 1998 with 4-cylinder engines.

1. Steering hydraulic pump

2. Stray pulley

3. Generator

4. Automatic tensioner

5. Air conditioning compressor (in the presence of)

6. Crankshaft pulley

7. Coolant pump

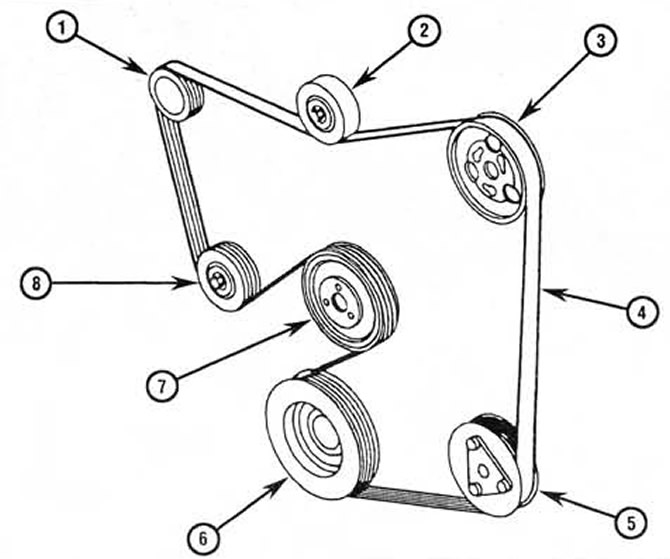

Pic. 5.1.6 Accessory Drive Belt Route - Models from June 1998 with 4-cylinder engines and air conditioning system (on models without this system, pulley 5 is missing)

Pic. 5.1.6 Accessory Drive Belt Route - Models from June 1998 with 4-cylinder engines and air conditioning system (on models without this system, pulley 5 is missing)

1. Generator

2. Stray pulley

3. Steering hydraulic pump

4. Belt

5. Air conditioning compressor (in the presence of)

6. Crankshaft pulley

7. Coolant pump

8. Automatic tensioner

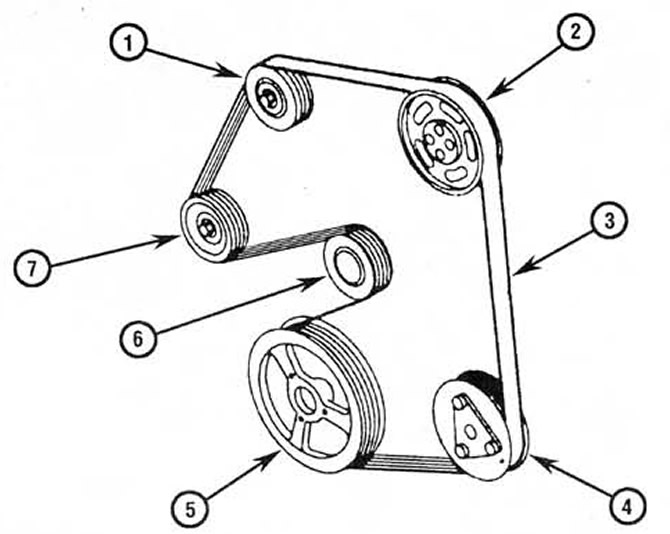

Pic. 5.1,c Accessory Drive Belt Route - V6 Models with Air Conditioning (on models without this system, pulley 4 is missing)

Pic. 5.1,c Accessory Drive Belt Route - V6 Models with Air Conditioning (on models without this system, pulley 4 is missing)

1. Stray pulley

2. Steering hydraulic pump

3. Belt

4. Air conditioning compressor (in the presence of)

5. Crankshaft pulley

6. Automatic tensioner

7. Generator

2. On 6-cylinder engines, the coolant pump is driven by a separate belt of the same type from the front intake camshaft.

3. The condition and tension of the accessory drive belt is very important for engine operation. The belt experiences heavy loads during operation and eventually stretches and wears out. Therefore, it must be checked regularly.

Examination

4. With the ignition off, open and lock the hood. The accessory drive belt is located on the right side of the engine, under the right engine mount bracket. Be careful and wear gloves to protect your hands from hot parts if the engine has just been turned off. To improve access, jack up the front of the car on the right side, place it on supports, remove the wheel, and then remove the accessory drive belt cover from under the wheel arch (secured with two clasps). If necessary, also remove the back of the locker, which is attached with two bolts.

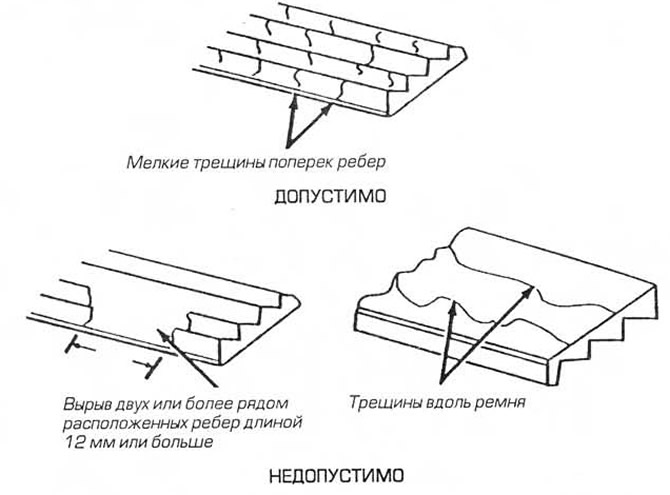

5. Using a flashlight or portable lamp for illumination, and turning the engine by the crankshaft pulley bolt, inspect the belt along its entire length for cracks, rubber peeling and worn streams (see fig. 5.5). Also make sure there are no shiny areas on the belt.

Pic. 5.5. Inspect the accessory drive belt for these signs of wear. Small cracks located across the walls of the stream are acceptable. If they are deep, or if the belt is worn or damaged, replace it.

Pic. 5.5. Inspect the accessory drive belt for these signs of wear. Small cracks located across the walls of the stream are acceptable. If they are deep, or if the belt is worn or damaged, replace it.

6. Inspect the belt on both sides. To do this, turn it with your fingers. If you are in doubt about the condition of the belt, replace it (see point 7).

7. On 6-cylinder models, remove the water pump drive belt cover from the top and front of the engine. Inspect the belt as indicated in p.p. 5, 6.

Belt tension

8. The accessory drive belt is tensioned by the automatic tensioner. Therefore regular checks and manual adjustments are not possible.

9. If you feel that the belt is slipping and/or loose or that the tensioner is faulty, then the tensioner needs to be replaced.

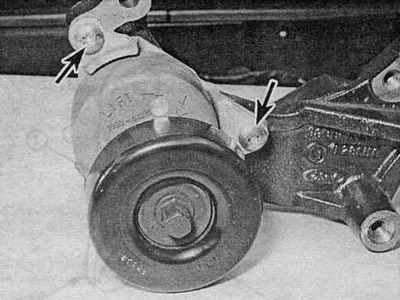

10. To do this, remove the belt (see below), remove the tensioner mounting bolts (two slotted head bolts are accessible from underneath the wheel arch) from generator support bracket (see fig. 5.10). The new tensioner must be properly installed on its supports and the bolts must be tightened to the required torque.

Pic. 5.10 The accessory drive belt is tensioned by an automatic tensioner. It is secured with two screws (shown by arrows) spline head on generator support bracket.

Pic. 5.10 The accessory drive belt is tensioned by an automatic tensioner. It is secured with two screws (shown by arrows) spline head on generator support bracket.

Replacement

11. Open the hood. Raise the front of the car on the right side, place it on a support, remove the wheel, and then remove the belt cover (secured with two clasps) from under the wheel arch.

12. If you reinstall a removed belt, mark it or note which side of the belt has the manufacturer's mark on a flat surface so that you can install the belt with the correct side.

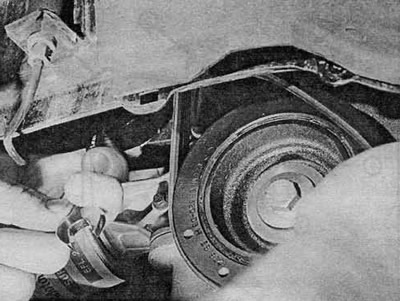

13. Turn the tensioner pulley clockwise so that it does not put pressure on the belt (see fig. 5.13). Depending on the model, the tensioner has either a hex wrench or a square hole into which a socket wrench can be inserted.

Pic. 5.13 Turn the tensioner pulley clockwise so that the pulley does not put pressure on the belt. Then remove the belt from the crankshaft pulley.

Pic. 5.13 Turn the tensioner pulley clockwise so that the pulley does not put pressure on the belt. Then remove the belt from the crankshaft pulley.

14. Remove the belt from the crankshaft pulley and release the tensioner. Then remove the belt from the remaining pulleys, remembering its original position.

15. Inspect all pulleys and remove all traces of oil from the grooves. Make sure the tensioner is working properly. When turning its pulley clockwise, you should feel the force of the spring, and when released, the pulley should smoothly return to its original position.

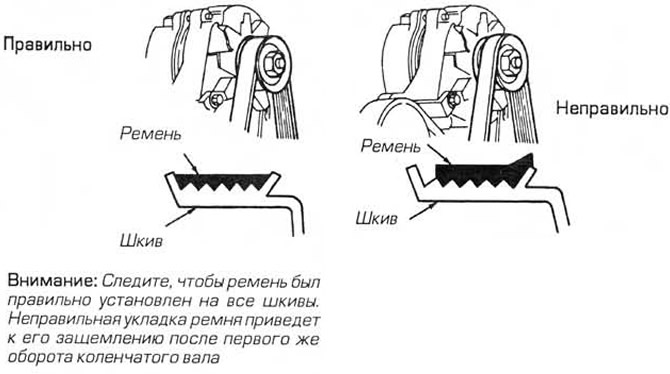

16. If you are reinstalling the removed belt, install it so that it rotates in the same direction. Control its position by the marks made during removal. When installing the belt, ensure that it fits into the grooves of the pulleys as shown in fig. 5.16. Make sure the belt is correctly positioned on the pulleys. Start putting on the belt from above, then put it on the lower pulleys, ending this procedure on the crankshaft pulley. Turn the tensioner pulley clockwise, tighten the belt onto the crankshaft pulley, and then release the tensioner again.

Pic. 5.16 When installing the belt, make sure that all of its ribs are in the grooves of the pulleys.

Pic. 5.16 When installing the belt, make sure that all of its ribs are in the grooves of the pulleys.

17. Rotate the crankshaft clockwise at least two full turns (turning it with a key on the pulley bolt) so that the belt settles on the pulleys. Then check the correct installation of the belt on the pulleys.

18. Install the removed components, then lower the vehicle to the ground.

Visitor comments