Withdrawal

Release models prior to 10.1996

Note: This procedure assumes that you are removing the head with the intake and exhaust manifolds attached to it. This simplifies the procedure, however, the assembly being removed is bulky and heavy, so you will need a lift. If you want to remove the manifolds first, follow the instructions paragraph 6 and 7 of this chapter, and then follow the head removal operations described in this paragraph.

1. Relieve pressure in the fuel system (chapter 4).

2. Park the vehicle on a firm level surface, open the hood and disconnect the negative battery cable (chapter 5 paragraph 1).

3. In any case, when you disconnect vacuum hoses, coolant hoses, ventilation hoses, electrical wire connectors, ground wires, fuel lines, which is provided by the following procedure, mark the detached elements with labels in order to install them in their places later.

4. Disconnect the two electrical wiring connectors, disconnect the vacuum hose (in the presence of), disconnect the crankcase breather hose from the head cover. Remove the air cleaner assembly along with the air mass meter, resonator and prechamber (chapter 4).

5. Equalize the pressure in the fuel tank with atmospheric pressure by removing the tank cap. Then disconnect the inlet and outlet fuel lines connecting the engine to the chassis (chapter 4) and plug any openings.

6. Disconnect the accelerator cable from the throttle actuator (chapter 4). Disconnect also the speed control cable (if available) (chapter 12). Fix the rope (s) away from the engine/transmission.

7. Remove the bolts and disconnect the steering hydraulic pressure line from the rear head base plate/engine load eye and from the pump bracket/front base plate. Release the wire clamp and disconnect the electrical connector of the wires of the contact pressure sensor of the hydraulic steering system. Then turn out a bolt and disconnect the tire of weight of a back support plate of a head of the block/engine cargo lug.

8. Turn out three screws of fastening of a trench of conducting from the back side of a collector. Disconnect the engine wiring from the main wiring harness by disconnecting the large electrical connector, (this connector is located next to the fuel pressure regulator) (see fig. 15.8, a). Disconnect the electrical connectors on each side of the ignition coil, as well as the connector located in front under the thermostat housing to disconnect the coil and the wiring of the coolant temperature gauge sensor (see fig. 15.8, b).

9. Disconnect the vacuum hoses in the following sequence (label them as you disconnect):

- A) One is from the rear of the throttle body. (Disconnect only one hose. The second hose going to the fuel pressure regulator does not need to be disconnected.)

- b) One - from the fitting at the sung end of the intake manifold 9, see fig. 14.9).

- V) Vacuum hose for brake booster (chapter 9).

- G) Disconnect all vacuum hoses from the EGR system components - one from the EGR valve and two from the EGR pipeline. Please note that the last two hoses differ in the size of the nozzles and therefore cannot be frightened.

10. Turn out bolts of both parts of the thermal screen of a final collector. Disconnect the coolant hose to remove the upper shroud. Remove the oil level dipstick together with its pipe or take them to the side.

11. Turn out a bolt of fastening of the case of the filter of system of afterburning of fuel to a forward arm of a support of the engine/transmission. Then disconnect the filter vacuum hose.

12. Empty the cooling system (Chapter 1).

13. Disconnect all coolant hoses from the thermostat housing (see fig. 15.13).

14. Turn away two nuts and disconnect a reception pipe of an exhaust system from a collector (chapter 4). Disconnect the oxygen sensor wiring so that it is not stretched by the weight of the exhaust system.

15. Remove the accessory drive belt (Chapter 1).

16. Jack up the engine/transmission with a piece of wood between its platform and the sump to prevent damage to the sump.

17. Turn away six nuts of fastening of the right arm of the engine/transmission, and then remove an arm. Remove the bolt of the parasitic pulley of the accessory drive belt (see fig. 14.17).

18. Turn out bolts of forward and back basic plates of a head of the block (see fig. 15.18, a, b).

19. Remove the toothed belt and camshafts (paragraph 10 and 13). If you disassemble the block head, pull out the hydraulic lifters.

20. Remove the inner casing of the toothed belt (paragraph 9).

21. In the reverse order shown in fig. 14.32, release ten bolts of the head of the block (loosening each bolt one turn at a time). This will require a slotted wrench (TX 55). These bolts must always be replaced with new ones after loosening (due to the complex nature of the workload they experience).

22. Remove the block head with an assistant (if possible), because it is heavy (see fig. 15.22). Remove the gasket paying attention to the dowel pins. The pad can be thrown away.

Release models since 10.1996

23. Disconnect the negative battery cable and empty the cooling system.

24. Apply the parking brake. Raise the front end and place it on stands. Remove the right front wheel.

25. Remove the mudguard from under the engine and the lower radiator shroud. On release models from 05.1998, remove the bolts and remove the accessory belt drive cover.

26. Place a container under the radiator. Then unscrew the drain plug so that the liquid flows into the container. On release models from 05.1998, disconnect the coolant hose located under the engine on the right. If necessary see chapter 1.

27. Remove the locker of the right front wheel arch.

28. Remove the accessory drive belt (see chapter 1).

29. On release models from 05.1998, remove the bolt and remove the water pump pulley and parasitic pulley. Also remove the crankshaft pulley and the lower timing cover (see paragraph 9).

30. On models with a 1.6 and 1.8 liter engine, remove the catalytic converter (see Chapter 4A).

31. Disconnect the engine wiring and brake booster vacuum hose from the intake manifold. Disconnect from a collector also a hose of compulsory ventilation of a crankcase.

32. Disconnect the oil pressure sensor wiring.

33. Turn out the central bolt of the limiter of a back roll of the engine. Remove the limiter from the subframe.

34. Turn out the central bolt of the limiter of a forward roll of the engine. Turn out nuts of fastening of the limiter to a stretcher. So far, the limiter has not been removed.

35. Remove air duct chamber, air duct and air cleaner cover (chapter 4A).

36. Disconnect the accelerator cable from the segment located on the throttle body.. Then pull off the plastic clip and disconnect the cable from the support bracket. Move the rope to the side.

37. Disconnect all vacuum hoses from the intake manifold,

38. Disconnect the wiring from the intake manifold, noticing its gasket. On release models from 05.1998, disconnect the wiring chute from the intake manifold.

39. Find the vacuum hoses of the RVG system valve and disconnect them.

40. Disconnect the wiring from the ignition coil, radio interference suppression device, and coolant temperature sensor.

41. Disconnect the wiring from the steering hydraulic pressure sensor and disconnect the ground wire from the engine load lug. Turn out bolts and remove an arm of a pipe of system of afterburning of fuel. On release models from 05.1998, unscrew the bolts of the oil level dipstick pipe from the block head.

42. On models with 2.0 liter engines, remove the air conditioning pipe bracket bolts.

43. Remove the bolts and remove the exhaust manifold heat shield and pull out the engine oil level control dipstick.

44. Turn out bolts and disconnect the RVG system valve from a final collector, a pipe of the RVG system from a cargo lug of the engine and the ignition coil.

45. On models with 2.0 liter engines, unscrew the nuts and disconnect the catalytic converter from the exhaust manifold. Then turn away nuts of unions and disconnect pipes of system of afterburning of exhaust gases.

46. Release the clamps and disconnect the cooling system hoses from the thermostat housing.

47. Disconnect the wiring from the coolant temperature gauge sensor.

48. On models with 2.0 liter engines, disconnect the crankshaft position sensor wiring. Then turn out bolts and remove the filter of system of afterburning of exhaust gases.

49. Mark the position of the right engine mount, then jack the engine up with a piece of wood. Turn out bolts of an arm of the right support of the engine.

50. Turn out bolts and nuts and remove an arm of a hydrosystem of a steering from a head of the block. On release models from 05.1998, unscrew the bolts of the expansion tank of the cooling system and move it to the side.

51. Turn out bolts and remove an arm of the generator from a head of the block.

52. Relieve residual pressure in the fuel system (chapter 4A).

53. Disconnect the quick couplings of the fuel inlet and outlet hoses.

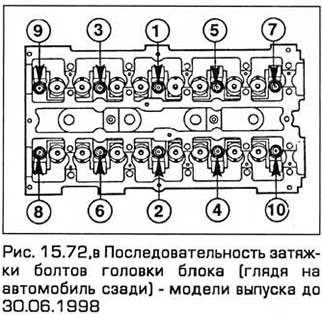

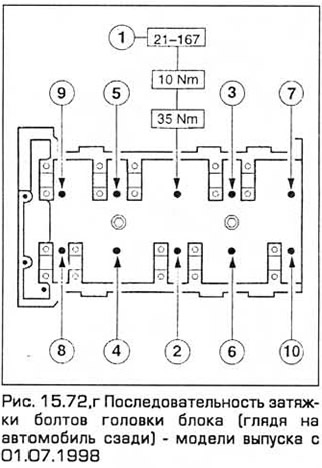

54. Turn out a bolt of a parasitic pulley of a belt drive of auxiliary units. Then remove the top and then the middle timing cover.

55. Disconnect the high voltage wires from the spark plugs. Then turn out bolts and remove a cover of a head of the block.

56. Remove the spark plugs. Pull out the engine oil dipstick.

57. Mark the timing belt to indicate the direction of rotation. Then loosen the tensioner nut and turn the tensioner pulley clockwise with a hex wrench. Lock the tensioner in this position by tightening the nut. Remove the belt.

58. Remove the toothed pulleys from the camshafts (paragraph 13).

59. Release bolts of covers of bearings of camshafts in the sequence shown on fig. 15.59. Turn out bolts and remove covers of bearings, camshafts and consolidations.

60. Remove the valve lifters and place them in a container with cells so that their position can be determined. If hydraulic clearance compensators are installed on the engine, they must be immersed in engine oil.

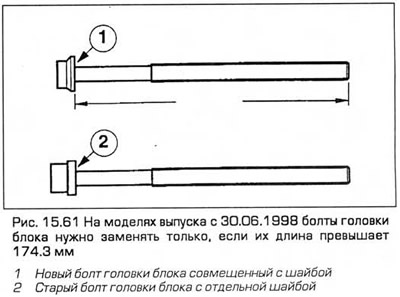

61. In the reverse order shown in fig. 15.72, in, gradually (one turn at a time) Loosen 10 head bolts. This requires a TX 55 wrench. Remove the bolts and inspect them for damage. It is recommended to always replace the block head bolts after they have been loosened. However, on production models from 06/30/1998, the bolts need to be replaced only if their length exceeds 174.3 mm (see fig. 15.61).

62. Remove the block head with an assistant, as it is heavy. Remove the gasket, noting the position of the pins, and discard it.

Installation

64. Check up interfaced surfaces of a head of the block and the block of cylinders on presence of dents, deep scratches and other traces of damages. Minor defects can be repaired with a file, but for significant damage, the damaged surface must be machined or the damaged component replaced.

65. If you suspect that the surface under the head gasket is warped, check it with the end of a metal ruler. See chapter 2B if necessary.

66. Clear interfaced surfaces of a head of the block and the block of cylinders. Make sure that the dowel pins are driven into the cylinder block and that the block head bolt holes are free of grease.

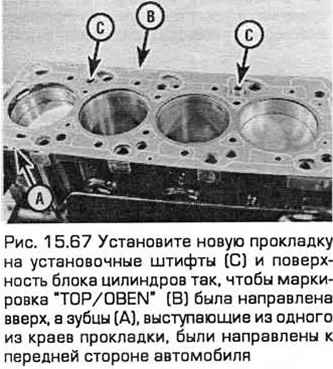

67. Install a new gasket on the locating pins and the surface of the cylinder block so that the marking "TOP/OBEN" pointing upwards, with the teeth protruding from one of the edges of the gasket pointing towards the front of the vehicle (see fig. 15.67).

68. Temporarily install the crankshaft pulley and turn the crankshaft counterclockwise so that the No. 1 cylinder piston is before TDC and about 20 mm below to protect the valves from damage during assembly.

69. The head of the block, together with the manifolds, is a bulky and heavy assembly. Therefore, it is recommended to make guides for mounting the head. Prepare two pins (M10 90 mm long) with a slot on one of the ends for a screwdriver. They can be made from old block head bolts by cutting off the heads. Screw these studs, slot end up, into the bolt holes located at the corners of the cylinder block diagonally to each other (or in holes designed for dowel pins). These studs should protrude approximately 70mm above the gasket.

70. Install the block head on the mounting studs and seat it on the mounting pins (see fig. 15.70). Remove mounting studs.

71. Insert new head bolts (but do not lubricate their threads). Tighten the bolts by hand.

72. In the sequence shown in fig. 15.72, c, d tighten the bolts in two steps indicated in the Technical data, first with a torque wrench, and then tighten them to the required angle using a head and a wrench, as well as a goniometer. (see fig. 15.72, a-g).

Note: Once the bolts have been tightened according to the Technical Data, the bolts should not be re-tightened or checked for tightness.

73. Install hydraulic lifters (if they were removed), camshafts, shaft seals and pulleys. Temporarily install the crankshaft pulley and turn the crankshaft clockwise until the notches on the pulley are in the position indicated in paragraph 10.

74. Install the toothed belt and covers, aligning the position of the camshafts (gas distribution mechanism) and restoring the toothed belt tension as indicated in paragraph 10.

75. The remaining installation operations are performed in the reverse order of removal, taking into account the following:

- A) Tighten all fasteners to the required torque.

- b) When installing the right engine/transmission mount, install the self-locking nuts and do not let the mount wobble when tightening the two in the middle (out of six) nuts.

- V) Drink liquid into the cooling system and top up the engine with oil.

- G) Immediately after starting and warming up the engine to normal operating temperature, inspect the joints and joints that have been disassembled for oil or coolant leaks.

Visitor comments