Special tool

| Wheel Bearing Cone/Seal Installer 205-296 (15-085) |

| Valve Spring Compressor 303-060 (21-024) |

| Adapter for 303-060 303-060-02 (21-024-02) |

| Adapter for 303-060 303-060-07 (21-024-07) |

| Stand 303-435 (21-187) |

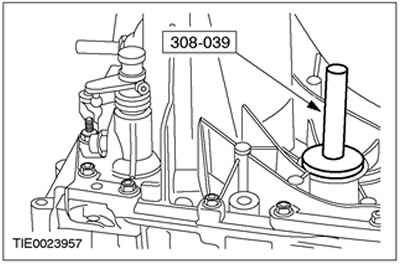

| Axle Seal Installer 308-039 (16018) |

| Input shaft bearing inner ring installation tool 308-041 (16-020) |

| Crankcase Bushing/Seal Installer 308-045 (16-015) |

| 308-076 Input Shaft Retaining Ring Installation Tool (16-031) |

General equipment:

- Press

- Dial indicator

- Magnetic Stand for Dial Indicator

- Technological plugs

| Name | Specification |

| sealant | ESEE-M4G1008-A |

| sealant | WSE-M4G323-A4 |

| sealant | WSK-M2G348-A5 |

| Transmission fluid for manual transmission | WSD-M2C200-C |

| High temperature grease | ESDM-1C220-A |

1. Carefully clean and check all parts before assembly.

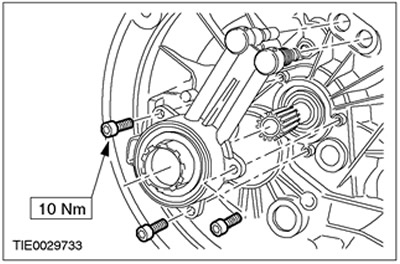

- Apply clean manual transmission fluid to all work surfaces.

2. Using the special tool, install the mainshaft tapered roller bearing and mainshaft bearing outer race.

- 1. Install the oil funnel.

- 2. Install the tapered roller bearing.

3. Using the special tool, install the differential bearing outer race.

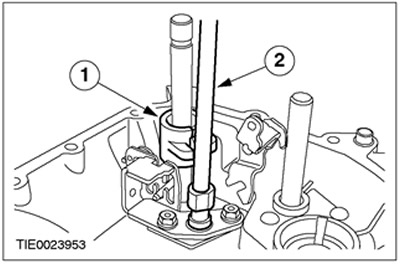

4. Install the 5th and reverse select shaft and shift lock bushing.

- 1. Install bushing.

- 2. Establish a shaft of a choice of transfers.

5. Install the reverse idle gear.

6. Install differential assembly and permanent magnet.

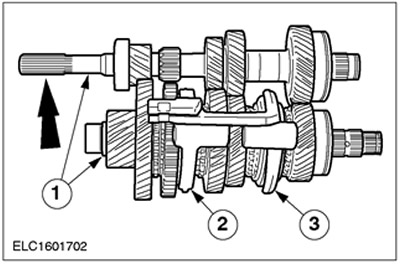

7. Prepare input and output shaft for installation.

- 1. Engage the input and output shafts.

- 2. Move the 1st and 2nd shift forks to the installation position.

- 3. Move the 3rd and 4th shift forks to the installation position.

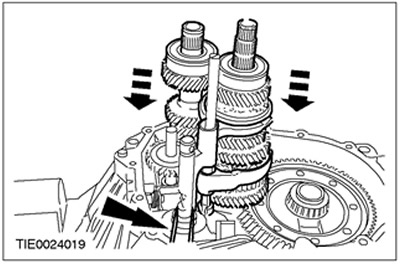

8.

NOTE: For ease of assembly, install a rubber band on the second selector shaft.

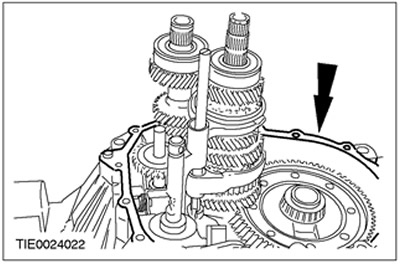

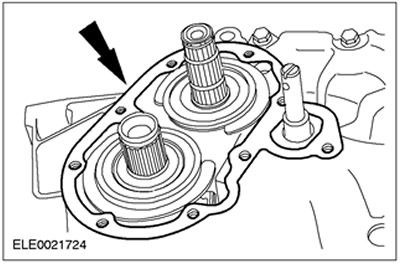

Install the input shaft and output shaft.

- Insert the input shaft to a depth of approximately 50 mm and move it slightly to the side.

- Insert the output shaft up to the level of the input shaft and engage the gears.

- Install the input shaft and output shaft.

9.

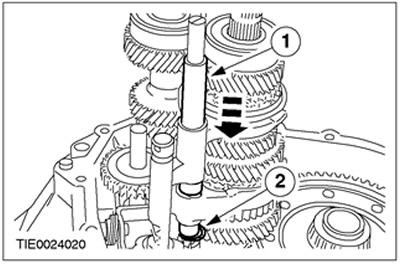

NOTE: Install a new retaining ring.

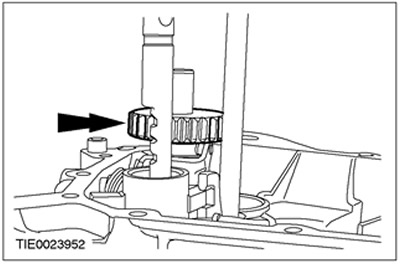

Install the lower circlip of the selector shaft guide bush.

- 1. Install the guide bush.

- 2. Install retaining ring.

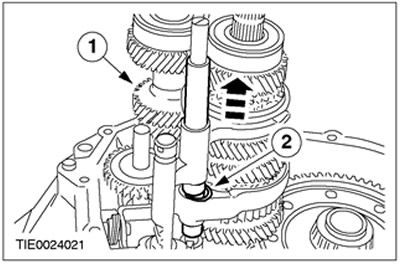

10.

NOTE: Install a new retaining ring.

Install the upper circlip of the selector shaft guide bush.

- 1. Raise the guide bush.

- 2. Install retaining ring.

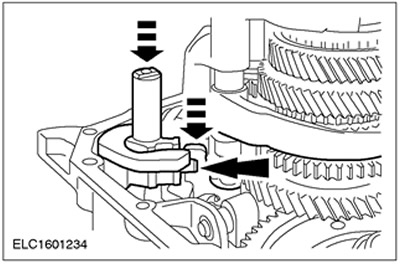

11.

NOTE: The surface of the shift lever pin must face the surface of the reverse idle gear lever.

Move the inner shift linkage towards the 5th gear.

- Before pushing down, turn the selector shaft clockwise until it reaches the reverse gear channel and 5th gear.

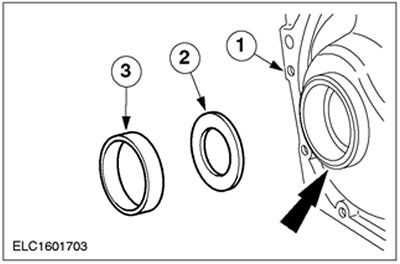

12. Install a 3.8 mm thick shim and lock it with a punch.

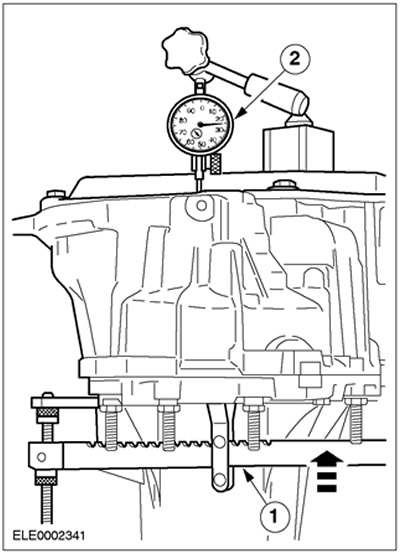

- 1. Transmission housing in a block with a drive axle

- 2. Gauge

- 3. Bearing outer ring

13.

NOTE: Make sure all mating surfaces of the transaxle case are clean.

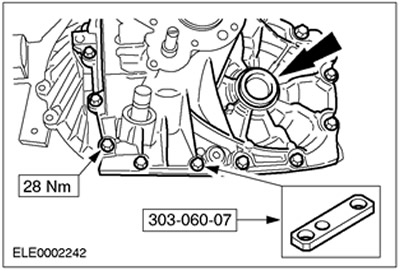

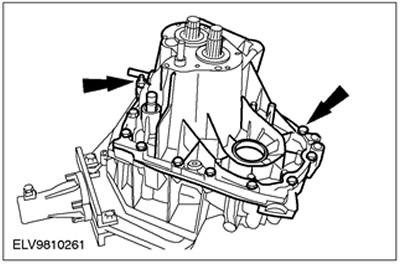

Assemble the gearbox housing in the block with the drive axle.

- Install the special tool.

- Install process plugs.

- Install bolts.

- Rotate the transaxle 180 degrees.

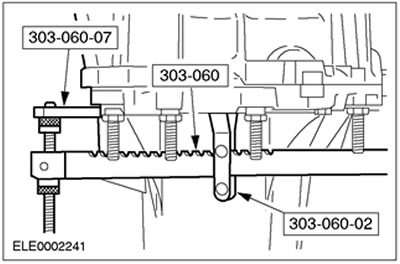

14. Install special tools. Remove technological plugs.

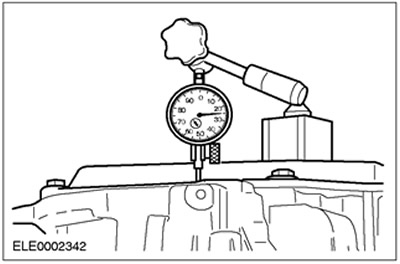

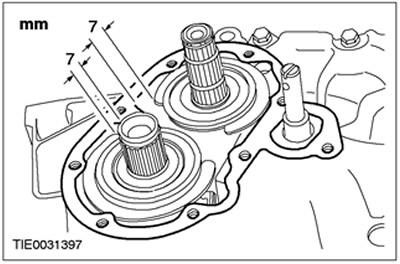

15. Using a suitable dial indicator, take a control measurement on the transaxle case face.

- Rotate the differential assembly approximately ten times to seat the bearings.

- Mount the dial indicator and magnetic stand and adjust the dial indicator to zero.

16.

NOTE: Perform the measurement procedure three times and calculate the average value.

NOTE: Shims are available in thicknesses from 0.1 mm to 1.1 mm in 0.1 mm increments.

Measure the end play of the differential.

- 1. Using the special tool, lift up the differential assembly.

- 2. Write down the measurement result (e.g. 0.73 mm).

- Example: 0.73mm + 0.74mm + 0.72mm divided by three = 0.73mm.

- The shim thickness value should be rounded down to the nearest tenth of a millimeter down if the resulting value is 0.05 mm or less, and rounded up to the nearest tenth of a millimeter up if the resulting value is 0.06 mm or more.

17. Calculate the required shim thickness.

- Shim Thickness = Shim (3.80 mm) + average value (0.73mm) + bearing preload (0.14mm) - thickness of spring washers (4.42 mm)

- Example: Shim = 3.80 mm + 0.73 mm + 0.14 mm - 4.42 mm = 0.25 mm.

- The thickness of the shim is 0.2mm (rounded down from 0.25 mm).

18. Disconnect the gearbox housing in the block with the drive axle.

- Install the top process plugs.

- Rotate the gearbox approximately 180 degrees.

- Remove the dial indicator, magnetic stand and special tools.

19. Using the special tool, remove the differential bearing outer race and shim.

20.

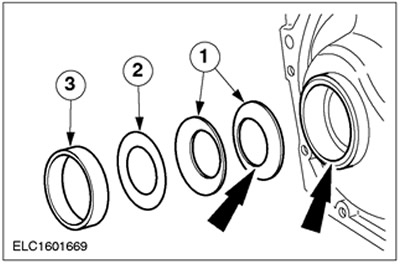

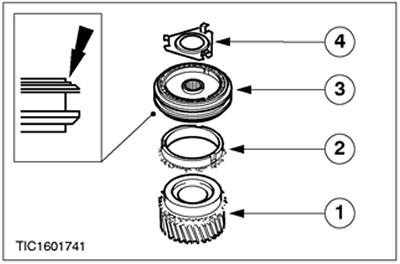

CAUTION: The spring washers must be installed so that the inner raised sections of both washers are in contact.

Install the measured shim.

- 1. Install spring washers.

- 2. Install the required shim.

- 3. Install the bearing inner race.

- Using a suitable center punch, lock the bearing inner race.

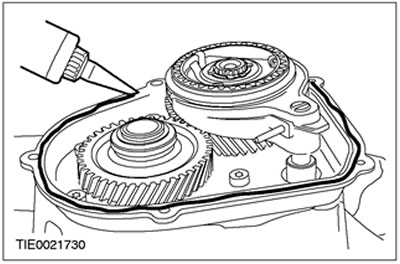

21. Apply sealant to the inner edge of the mating surface of the transaxle housing.

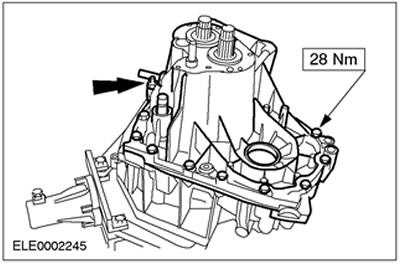

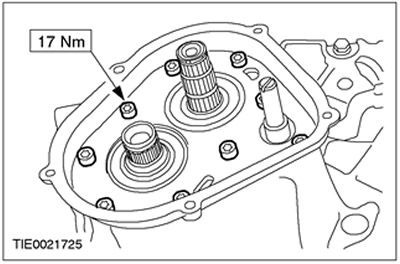

22. Assemble the gearbox housing in the block with the drive axle and tighten the bolts.

23.

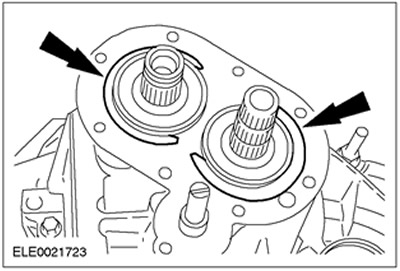

NOTE: Install new circlips for input and output shafts.

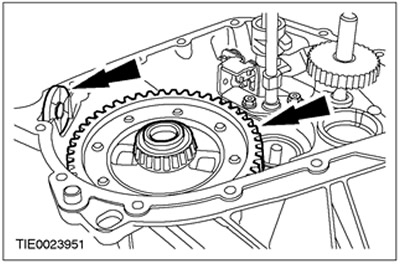

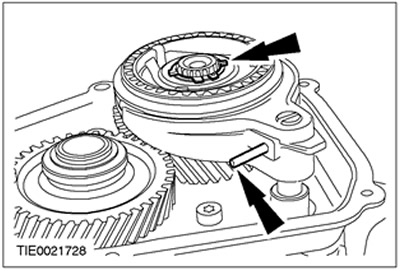

Raise the input and output shafts slightly and install the circlips.

24.

CAUTION: Make sure the circlips are in the correct position. Failure to follow this instruction may result in damage to the 5th gear housing.

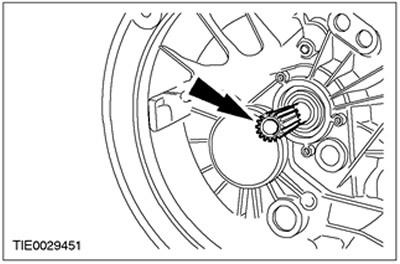

Rotate the circlips to the position shown.

25.

NOTE: Install a new 5th gear housing gasket.

Install the 5th gear housing gasket.

26.

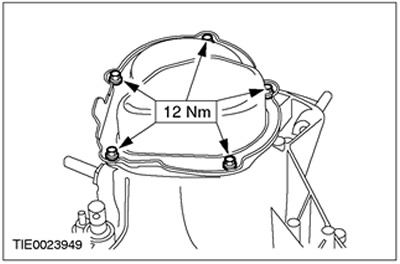

NOTE: Install new 5th gear case mounting bolts.

Install the 5th gear housing.

27. Remove the gearbox in the block with the drive axle from the assembly stand.

28.

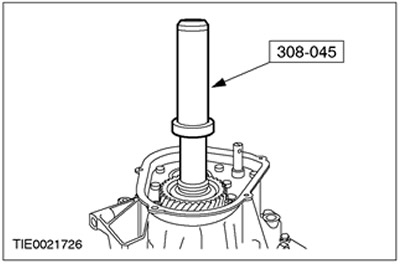

NOTE: The transaxle case must not come into contact with the press table. Support the input shaft splines.

Using the special tool and a suitable press, install the 5th gear

29. Install the gearbox in the block with the drive axle on the assembly stand.

30.

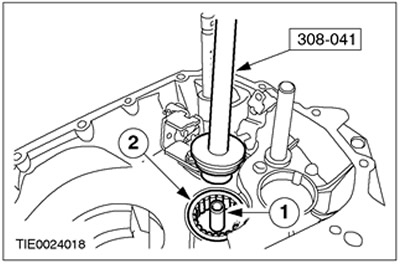

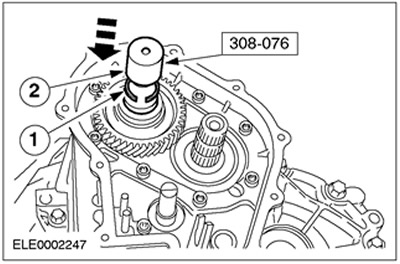

NOTE: Install a new 5th gear retaining ring.

Install the 5th gear snap ring.

- 1. Install the circlip on the special tool.

- 2. Install the special tool and press on the circlip.

31.

NOTE: Align the position of the transfer synchronizer with respect to the marks.

Assemble the 5th gear synchronizer.

- 1. Install the 5th gear.

- 2. Install the synchronizer ring.

- 3. Install the synchronizer assembly.

- 4. Install the mounting plate.

32.

NOTE: Install a new 5th gear synchronizer retaining ring assembly.

NOTE: Use a new selector fork mounting pin.

Install the 5th gear synchromesh assembly and selector fork.

- Install the pin.

- Install retaining ring.

33. Apply sealant evenly to the inner edge of the mating surface of the 5th gear housing.

34. Install the 5th gear housing cover.

35.

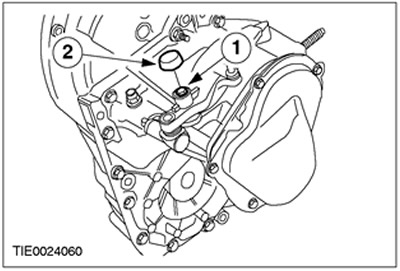

NOTE: Make sure the selector shaft is in the neutral position.

Shown is the correct installation position for the selector shaft lock mechanism.

36.

NOTE: Make sure the selector shaft is in the neutral position.

Establish the mechanism of blocking of a shaft of a choice of transfers. Apply thread sealant.

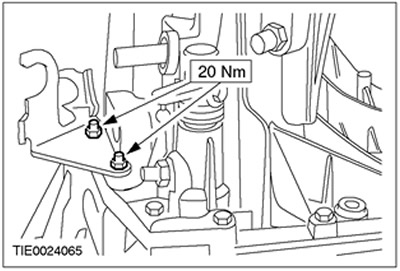

37. Install the select lever. Install the cover.

38. Engage 5th gear.

- Turn the selector shaft clockwise until it stops and push the selector shaft inward.

39.

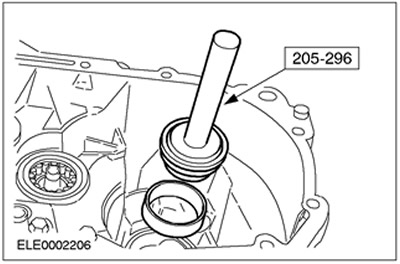

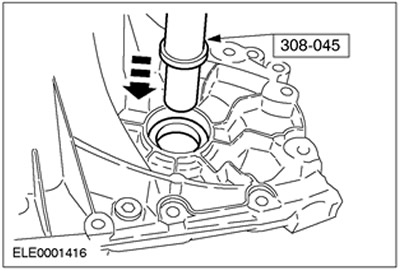

NOTE: Install new axle shaft oil seals.

Using the special tools, install the oil seals on both axle shafts (left side shown).

40. Install the shift cable support bracket.

41.

NOTE: Install a new retaining ring.

Install the shift lever.

- 1. Install retaining ring.

- 2. Install the protective cover.

42. Establish a cover of the mechanism of a choice of transfers.

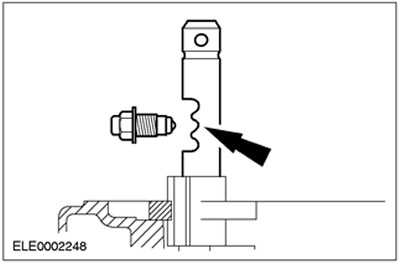

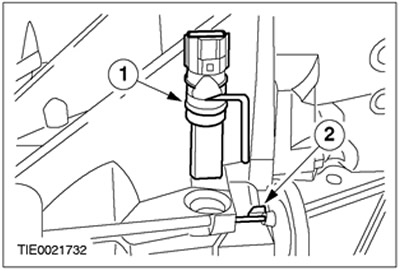

43. Install the vehicle speed sensor (VSS) (in the presence of).

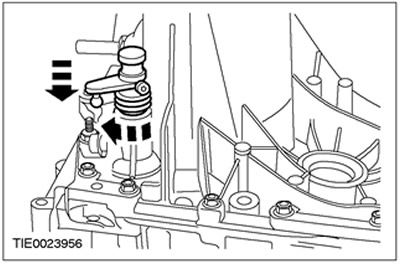

- 1. Press down on the VSS.

- 2. Install the pin.

44.

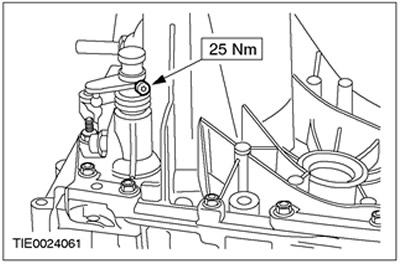

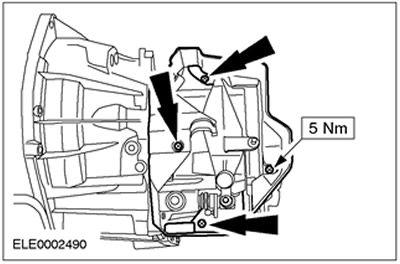

CAUTION: Using suitable adhesive tape, cover the input shaft splines to prevent damage to the input shaft oil seal.

Install the input shaft oil seal.

45.

WARNING: If brake fluid comes into contact with the paintwork, the affected area must be washed immediately with cold water.

CAUTION: Do not apply lubricant to clutch slave cylinder components.

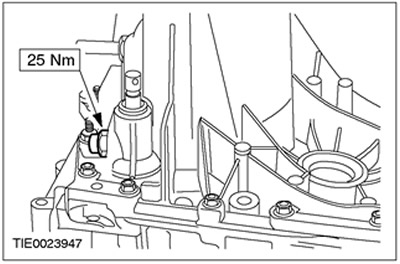

Install the clutch slave cylinder.

46. Remove adhesive tape from input shaft splines.

47. Apply a thin coat of high temperature grease to the input shaft splines.

Visitor comments