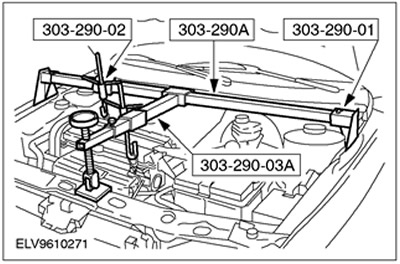

Special tool

| Engine support beam 303-290 (21-140) |

| Adapter for 303-290 303-290-01 (21-140-01) |

| Adapter for 303-290 303-290-02 (21-140-02) |

| Adapter for 303-290 303-290-03 (21-140-03) |

General equipment: Gearbox jack.

| Name | Specification |

| transmission fluid | WSD-M2C200-C |

Installation

1. General notes:

- Use only new self-locking nuts.

2. Move the gearbox to the installation position using a gearbox jack and secure it to the engine.

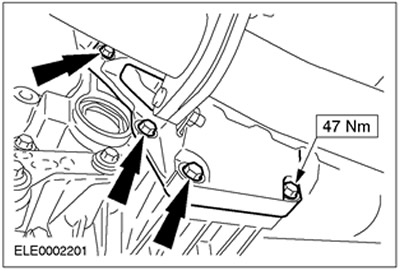

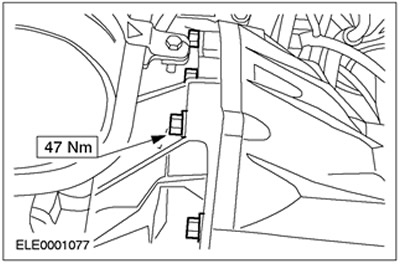

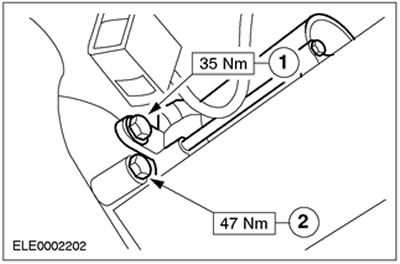

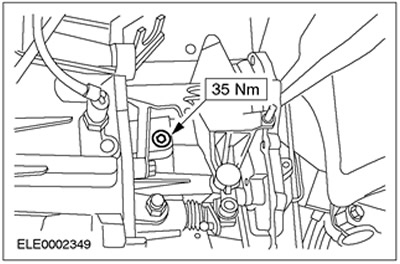

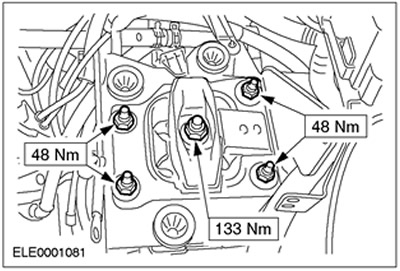

3. Tighten the flange bolts.

4. Tighten the flange bolts.

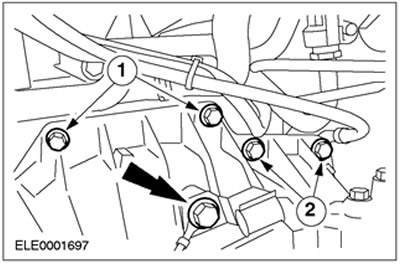

5. Install starter and tighten flange bolts.

- 1. Starter bolt

- 2. Flange bolt

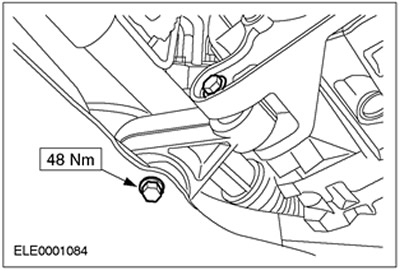

6. Install the roll limiter.

7.

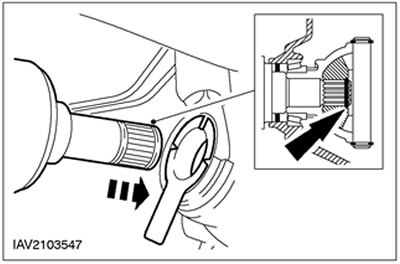

CAUTION: Support axle shaft. The inner hinge should not be tilted more than 18 degrees. External hinge - at an angle exceeding 45 degrees.

CAUTION: To protect the oil seal, use a dowel sleeve when installing the front axle shaft (comes with every new oil seal).

CAUTION: Do not damage the oil seal.

CAUTION: Make sure the snap ring is installed correctly.

NOTE: Attach the tripod joint assembly (continuation).

Establish the left semiaxle on a transmission.

8.

CAUTION: Support axle shaft. The inner hinge should not be tilted more than 18 degrees. External hinge - at an angle exceeding 45 degrees.

CAUTION: To protect the oil seal, use a dowel sleeve when installing the front axle shaft (comes with every new oil seal).

CAUTION: Do not damage the oil seal.

Establish the right semiaxle on a transmission.

9.

NOTE: Install new bracket and new intermediate bearing nuts.

Connect the bracket for fastening the intermediate bearing of the right axle shaft.

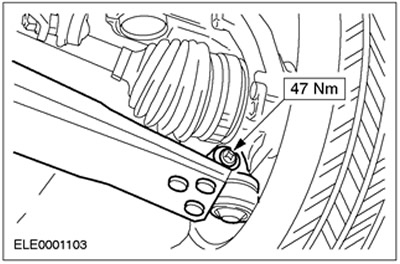

10. Install the lower control arm ball joints on both sides (right side shown).

11. Install selector and shift cables.

- Install the shift and select cables to the bracket by turning the bushing clockwise.

12. Fill in the transmission fluid; transmission fluid should be filled to a level 5-10 mm below the lower edge of the inspection hole.

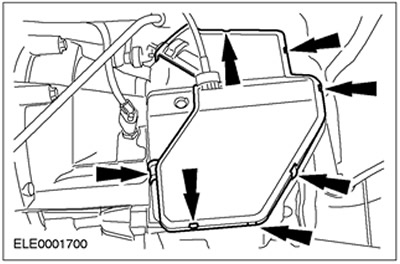

13. Close the cover of the shift cables and gear selection.

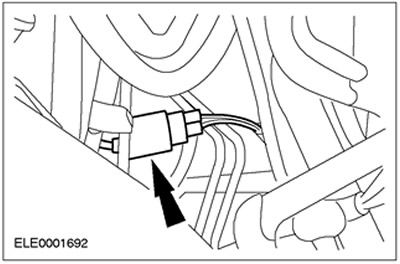

14. Dock the reversing light switch connector.

15. Lower the car.

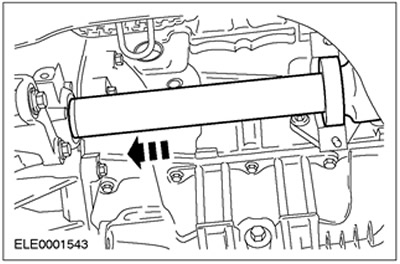

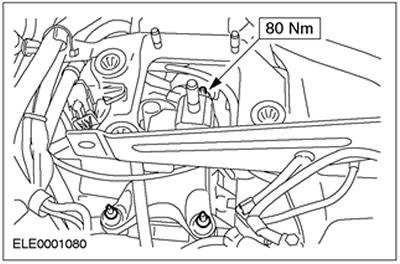

16. Using special tool 308-290 (21-140) Raise the engine and transmission just enough to allow the rear engine mount to be installed.

17. Install the rear engine mount bracket.

18. Install the rear engine mount.

19. Disconnect special tools.

20. Tighten the top flange bolts and starter bolts.

- 1. Flange bolts

- 2. Starter bolts

- Connect the ground wire.

21.

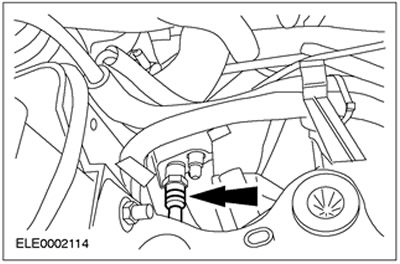

CAUTION: Brake fluid leakage. Observe precautions for handling brake fluid.

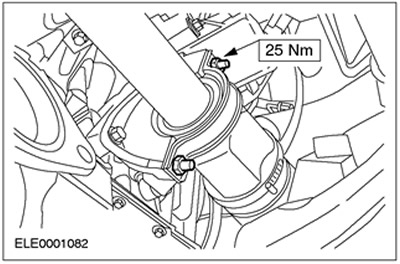

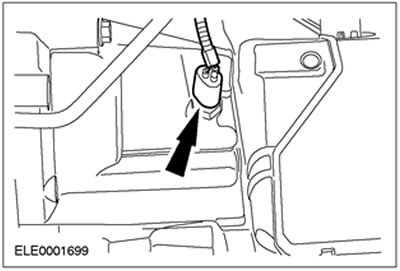

Install the high pressure line for the clutch slave cylinder.

22. Insert the clutch hydraulic line into the locking element.

23. Remove air from the hydraulic clutch. See Section 308-00 for more information.

24. Connect the vehicle speed sensor connector (VSS).

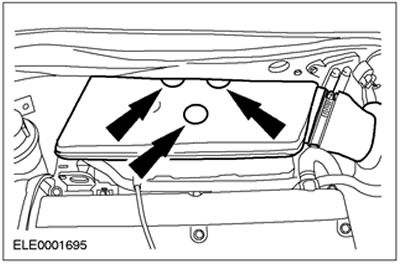

25. Install the air filter.

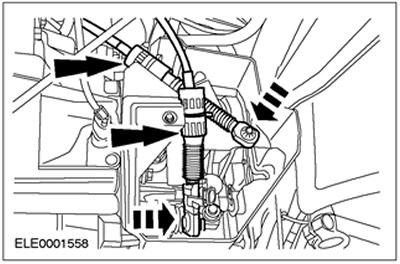

- Insert the air filter with inlet hose and air chamber and tighten the screws.

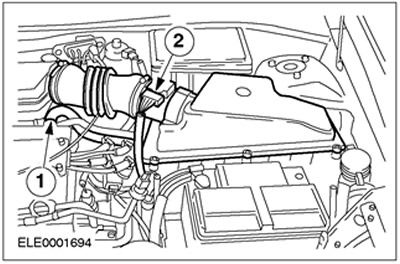

26. Install the air filter.

- 1. Install the crankcase ventilation hose.

- 2. Dock the MAF sensor connector (MAF sensor).

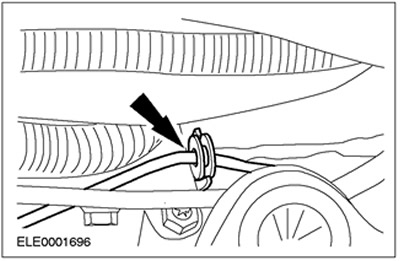

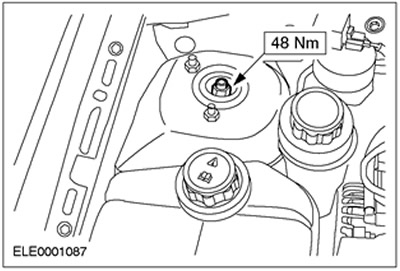

27. Tighten the left and right suspension strut nuts.

- Stop the piston rod from turning with an Allen wrench.

- Tighten by hand with a ring wrench.

- Tighten to the prescribed torque using a torque wrench.

28. Adjust the gearshift mechanism. See Section 308-06A / 308-06B / 308-06C for more information.

29. Standard final operations:

- Check the wiring of the vacuum hoses and electrical wiring and fix them with clamps.

- Enter the radio key code.

- Reprogram preset radios.

- Set your clock.

- Carry out a road test to give PCM a chance to collect data.

- Recheck fluid levels and correct if necessary.

Visitor comments