Disconnect the speedometer drive from the gearbox.

Disconnect the control cable from the clutch release forks.

Remove the flexible gearbox ventilation hose from the hole in the side member of the body.

Unscrew the upper bolts on the gearbox housing flange.

Disconnect the chassis ground wire.

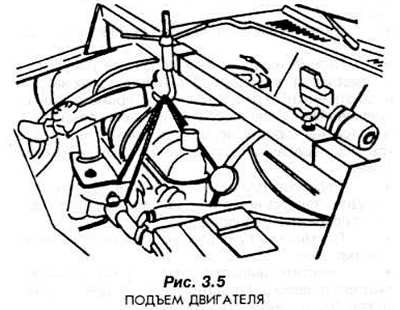

Attach the hoist hook and raise the engine slightly (pic. 3.5).

Raise the vehicle.

Disconnect the reversing lamp wire connector.

Remove the starter.

If necessary, remove the brackets and fasteners of the exhaust system.

Remove the clutch housing cover.

Disconnect the rod (barbell) gear change from the gear selector shaft.

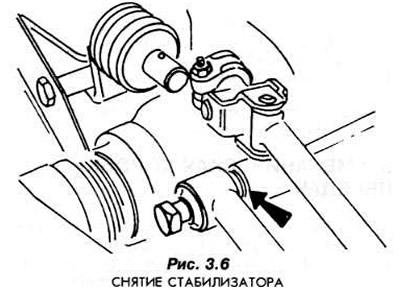

Unscrew the stabilizer from the gearbox (pic. 3.6).

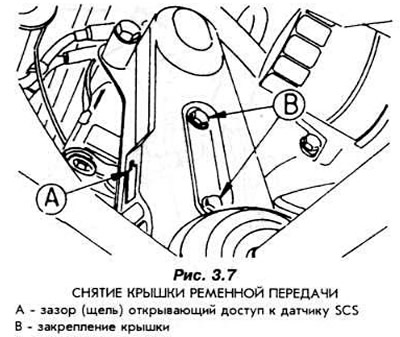

Disassemble the ball joints of the suspension columns on both sides of the vehicle and disconnect the columns from both transverse levers. In vehicles with an anti-skid system in the brake system (SCS - ABS) you must additionally perform the following steps:

Disconnect the electrical connector from the sensor (see fig. 3.7).

Remove the belt drive cover.

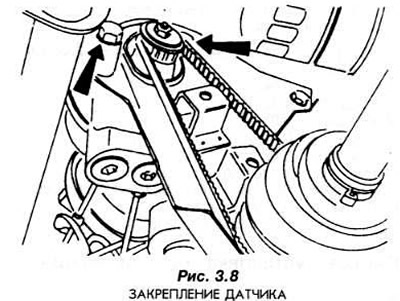

Remove the sensor (SCS) wheel speed (pic. 3.8).

Remove the inner belt drive cover.

Remove the two axle shafts from the gearbox. In a car with a semi-axle consisting of two parts, it is necessary to unscrew the intermediate bearing housing from the engine. Then remove the rubber cover (from the gearbox side) and remove the axle shaft together with the intermediate shaft from the gearbox housing.

Hang the axle shaft on a wire hooked to the body. The axle shaft must not hang down, as this will cause damage to the hinges.

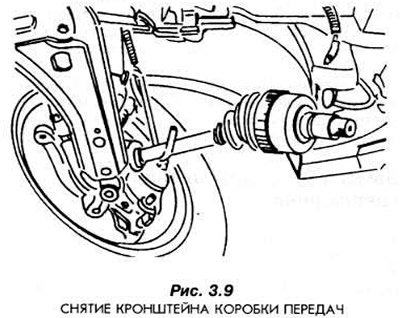

Remove the gearbox bracket from the body (pic. 3.9).

Lower the engine as low as its suspension allows. Unscrew nuts of a back suspension bracket of a transmission (pic. 3.10).

Unscrew the rear mounting studs from the box.

Unscrew the bottom bolts of fastening of a flange of the case of a transmission.

The gearbox is installed in the reverse order. In this case, the recommended tightening torques for bolts and nuts should be strictly adhered to. The method of adjusting the gear connection mechanism has been described in the section 2.1 "Engine replacement".

Visitor comments