Remove the stabilizer 2 installed between the gearshift drive and the gearbox. Hang the stabilizer and drive rod to the steering gear housing. Carefully unscrew the selector rod retainer, remove the lock pin and spring. After removing the retainer, almost all the oil will flow out of the gearbox housing (pic. 3.10).

Detach lower control arm ball joints from steering knuckles and move control arms to one side. Using a large screwdriver, pry the front driveshaft inner pivots out of the side gears and replace them with process plastic mandrels or old pivots to hold the side gears in place. Suspend the drive shafts to the body in such a way that the bending angle of the inner joint does not exceed 20°, and the outer joint does not exceed 45°. Unscrew the four bolts securing the gearbox to the bracket and one nut securing the bracket itself. Unscrew the three bolts securing the gearbox to the rear bracket and one bolt securing the bracket (for a five-speed gearbox, move the stabilizer bar on the left side to the side).

Unscrew the two lower bolts securing the clutch housing to the engine, lower the engine so. to be able to remove the gearbox. Before installing, apply a light film of grease to the splined end of the input shaft and to the outer surface of the clutch release bearing sleeve guide bush. that the gasket between the engine and the clutch housing is in the correct position on the dowel sleeves (pic. 3.11), insert the end of the input shaft of the gearbox into the splined hole of the driven disk and move the gearbox forward until the clutch housing comes into contact with the rear mating plane of the engine and tighten the bolts securing the gearbox to the engine to a torque of 3.5-4.5 kgf·m and to the power suspension bracket unit with a moment of 8.0-10.0 kgf·m.

Screw, without tightening, the bolt of the bracket for the rear gearbox support. For a five-speed transmission, reinstall the stabilizer bar on the left side. Next, for all gearboxes, tighten the rear support bolts, install the retainer, retract spring and gearshift linkage. Replace the retaining rings on the inner hinges of the wheel drive shafts with new ones, remove the technological mandrels and install the shafts in the gearbox, pressing hard on the shafts so that the retaining rings enter the grooves of the side gears. Reinstall the lower suspension arms Install the washer between the gearbox housing and stabilizer bar 2 (pic. 3.9) and tighten the bolt to a torque of 1.7-2.0 kgf·m.

Four speed gearbox

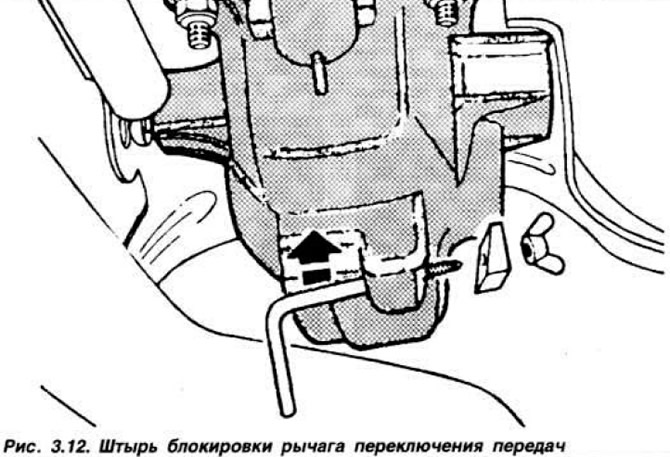

Using a 3.5 mm pin (pic. 3.12) lock the gear lever in the cup of its ball joint, attach the spring to the drive rod and to the body side member.

To evenly distribute the gaps, push the gear selection shaft into the 4th gear position. turn clockwise until it stops.

Five-speed gearbox

After installing the stabilizer, turn on the reverse gear. for this purpose, set the gear selection shaft to the neutral position, then use the pin to turn it clockwise until it stops and sink it completely deep into the gearbox housing.

For all gearboxes

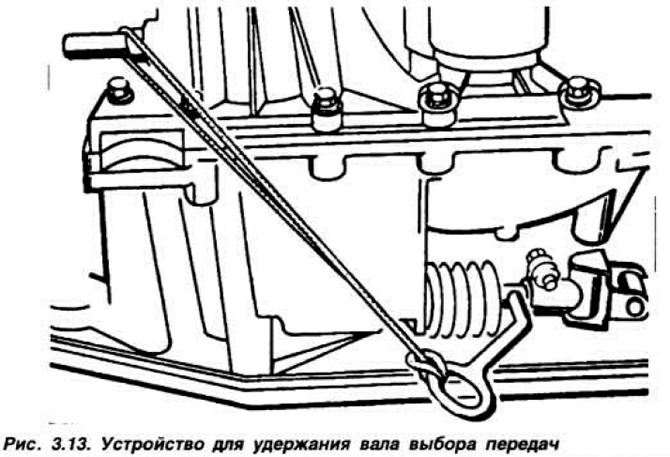

Use a tool to hold the selector shaft in this position. shown in fig. 3.13.

Connect the drive rod to the shaft, while the shrink coupling must be free of grease. Tighten the bolt of the turnbuckle of the drive rod on the rod with a torque of 1.7-2.0 kgf·m and remove the pin. Reinstall the clutch housing cover and lower the vehicle to the floor. Remove the brace to lift the engine. Install the upper gearbox housing bolts. Connect the clutch cable and install the speedometer drive. Fill the gearbox with oil. Connect the hose to the thermostat housing and heater and connect the battery. Insert the crankcase breather hose into the recess in the side member.

Visitor comments