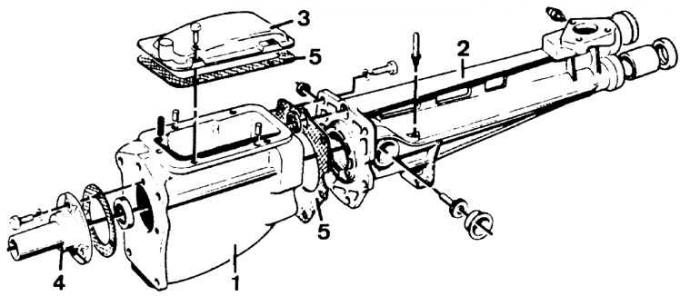

Type C manual gearbox housing

1 - front part of the crankcase; 2 – a back part of a crankcase; 3 - cover; 4 - guide sleeve of the clutch release bearing; 5 - cover gasket

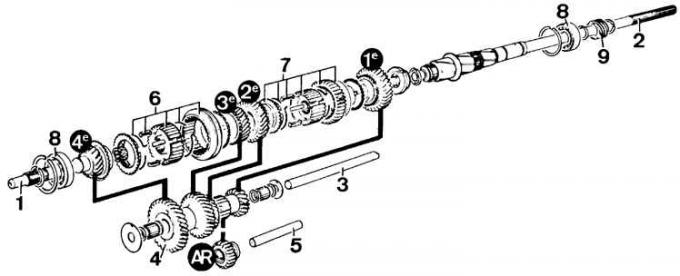

Type C manual transmission gears

1 - input shaft; 2 - secondary shaft; 3 - the axis of the block of gears of the intermediate shaft; 4 - gear wheel of constant engagement of the intermediate shaft; 5 – an axis of an intermediate gear wheel of a reverse gear; 6 - synchronizer of 3rd-4th gears; 7 - synchronizer of 1st-2nd gears; 8 - precision bearing; 9 - speedometer drive gear

The black circles show the gear numbers of the individual gears (AR - reverse gear).

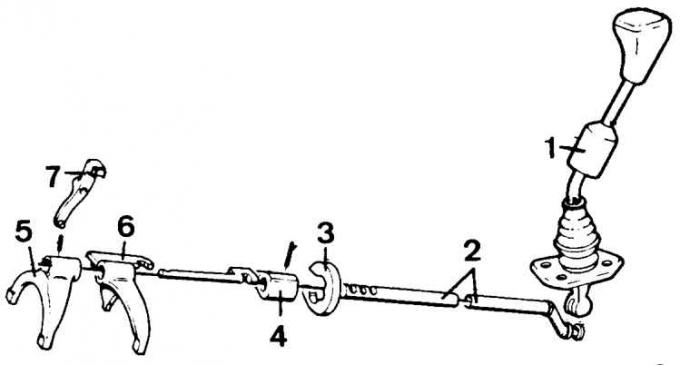

Type C Gear Shift Mechanism

1 – gearshift lever; 2 - control rod; 3 – fixation device ring; 4 - selector; 5 - forks 3rd-4th gears; 6 - forks 1st-2nd gears; 7 - reverse gear forks

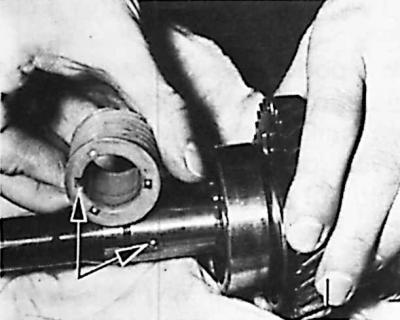

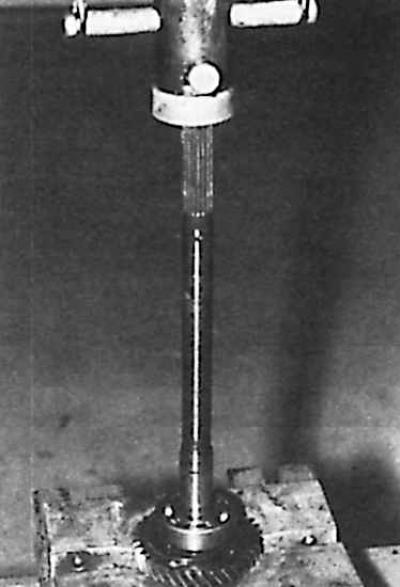

Dismantling the output shaft

1. Remove the circlip from the socket at the rear of the gearbox housing.

2. Remove the complete output shaft (hitting with a hammer).

3. Remove the 3rd-4th gear synchronizer hub circlip, remove the synchronizer hub and 3rd gear (you can use a universal puller with two cheeks).

4. Remove the retaining ring and remove the speedometer drive gear, as well as the latch ball, from the secondary shaft.

5. Remove the circlip, precision bearing, and O-ring from the output shaft; in the process of performing this operation, rest the 1st gear on a steel stand in the form of the letter U of the appropriate dimensions.

6. Remove the 1st-2nd gear synchronizer hub retaining ring, and then remove the 1st-2nd gear synchronizer completely.

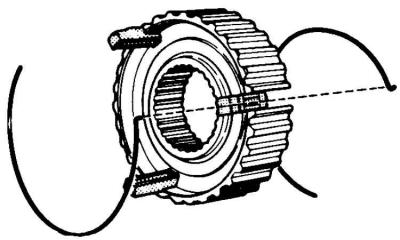

7. Remove the two synchronizer hubs, sliding sleeves, remove crackers and springs.

8. Raise the car.

9. Clutch shield.

10. Lower bolts securing the clutch housing to the cylinder block.

Output shaft assembly

1. Thoroughly clean all parts and check their technical condition, and lubricate with gearbox oil before assembly.

2. In the case of installing new factory parts, their working surfaces, as well as the interacting surfaces of the output shaft, should be coated with special grease S-MIC-4505 A.

3. "Glue" with the help of lubrication of the crackers of the clamps to the hubs of the synchronizers of the 1st–2nd and 3rd–4th gears. Insert the sliding sleeves of the synchronizers on the hubs and install in accordance with their designations.

4. Insert the hub with the 1st-2nd gear synchronizer sleeve onto the output shaft, pointing back the groove of the sleeve intended for the forks. Install retaining ring.

5. Insert synchronizer ring and 1st gear. Insert the sealing ring so that its larger diameter is on the side of the gear.

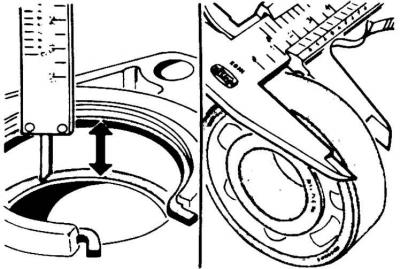

6. Determine the thickness of the required spring ring fixing the bearing on the secondary shaft. To do this, proceed in the same way as in the case of gearbox type A (see subsection 6.1.4).

7. Install a ball bearing on the output shaft, as well as a retaining ring of the required thickness.

8. Coat the surface of the ball bearing with a multipurpose grease for precision bearings.

9. Press the ball bearing into place on the output shaft using an appropriately sized bushing or other suitable multipurpose tool.

10. Install the speedometer drive gear on the output shaft and install the output shaft so that the recess on the retainer ball is on top. Install the retainer ball in the socket, correctly install the speedometer drive gear on the shaft and fix it with a retaining ring.

11. Install the 3rd-4th gear synchronizer on the output shaft with the annular thickening forward. Install retaining ring.

12. Warm up the rear of the gearbox housing by immersing it in hot water and installing the output shaft in it.

13. Insert the retaining ring in the desired location. This ring should be in the slot at the rear of the gearbox housing.

Disassembly and assembly of the primary and intermediate shaft

1. Remove the circlip and bearing from the input shaft.

Attention! To facilitate the subsequent installation of the bearing, install a large diameter retaining ring in its place.

2. Coat the input shaft precision bearings with multipurpose grease, press in the bearing and remove the large diameter circlip.

3. Extract (inserted during the removal of the intermediate shaft axle) rod from the hole in the gear block of the intermediate shaft. Remove the 29 bearing needles and thrust washers from both sides of the countershaft gear assembly.

4. Re-insert the removed rod into the hole in the gear assembly. Fill the space between the rod and the hole in the intermediate shaft gear assembly on both sides with multipurpose grease.

5. Install in order on both sides: spacer, set of bearing needles and second spacer.

6. Use a screwdriver to remove the O-ring from the outer race of the input shaft bearing.

7. Coat the lip of the sealing ring with multipurpose grease.

8. Using a suitable tool, carefully press a new O-ring into the input shaft bearing.

Visitor comments