Attention! This section applies to gearboxes of all types.

Disassembly

1. Remove the release bearing and clutch release forks.

2. Fix the gearbox on the work table.

3. Unscrew the ten mounting bolts and remove the gearbox cover.

4. Rotate the gearbox and drain the oil.

5. Using a screwdriver inserted into the hole for the gear selector shaft, remove the cover located at the end of the rear of the gearbox housing.

6. Unscrew the plug on the side of the crankcase to block the internal gearshift mechanism, remove the spring under it and pull out the stopper using a magnetized rod.

7. Remove the pin from the blocking assembly, as well as the plug in the rear of the crankcase and remove the cotter pin.

8. Remove the reverse gear selector cam pin and pull its shaft back.

9. Remove two pairs of forks and two stoppers.

10. Using tool 17.001 remove the O-ring from the rear of the gearbox housing (the output shaft must be in place).

11. Unscrew the bolts securing the rear of the gearbox housing, disconnect it from the front of the housing and easily turn in both directions to get the intermediate shaft.

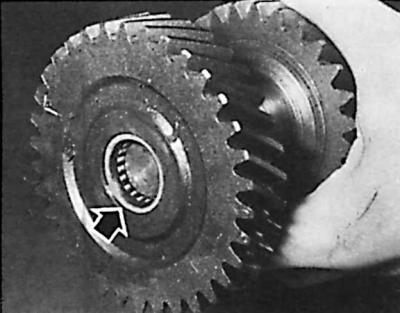

Attention! The intermediate shaft is a block of five gears that form one whole and rotate on bearings located on the axis.

12. Move the intermediate shaft back to release it from the front stop.

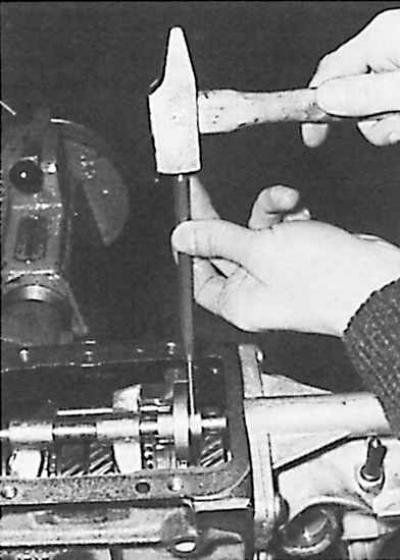

13. Pull out the layshaft using tool 16.002, holding the shaft bearing with an auxiliary tool against the shaft to be taken out so that the bearing remains in place.

14. Remove the rear of the gearbox housing.

15. Unscrew the four bolts securing the input shaft bearing. Remove the input shaft with its needle bearing.

16. Remove the gear cluster from the countershaft axle using an auxiliary tool and remove the two thrust washers from the gearbox housing.

17. Remove the ring from the axis of the reverse gear lever and remove this lever.

18. Remove the speedometer drive gear cover and remove this gear from the rear of the transmission case.

Assembly

1. Thoroughly clean all parts of the gearbox and lubricate them with gearbox oil. The threads of the bolts entering the gearbox housing should be coated with sealing paste.

2. Insert the reverse gear lever onto the axle and secure it with the ring.

3. Install the reverse idle gear on this lever; the forks point backwards; install the pinion against the axle lubricated with grease, and with blows of a copper hammer, fit the pinion.

4. Install the thrust washers of the intermediate shaft gear assembly with grease in the recesses provided for them in the crankcase.

5. Carefully insert the countershaft gear assembly into the gearbox housing. Install the thrust washers with the projections in the corresponding recesses.

6. Install the input shaft and its bearing in the gearbox housing. Rest the snap ring against the crankcase wall.

7. Install the precision input shaft bearing with a new O-ring and screw in the four mounting bolts, the threads of which should be coated with sealing paste.

8. Install a needle bearing lubricated with oil on the input shaft and install the 3rd-4th gear synchronizer sleeve.

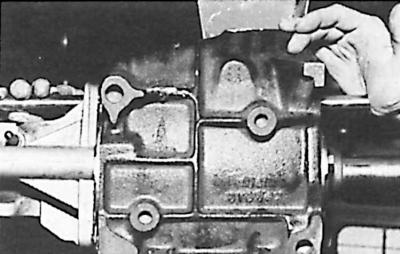

9. Install the rear of the gearbox housing and output shaft. Rotate the crankcase so that the intermediate shaft shaft can be inserted (a gasket should be glued with grease on the surface of the crankcase connection to protect it from damage).

10. Tilt the gearbox so that the intermediate shaft gears engage the input shaft gear and output shaft gears. Check that the two thrust washers are in place. Insert, with blows of a copper hammer, the axle of the intermediate shaft at the rear of the crankcase, keeping it all the time in contact with the pin, which facilitates installation, until its top is level with the clutch housing. The flat protrusion of the rear part of the intermediate shaft axle must be installed horizontally.

11. Position the rear of the gearbox housing on the extension of the front, lubricate the threads of the mounting bolts with sealing paste and tighten them to the correct torque.

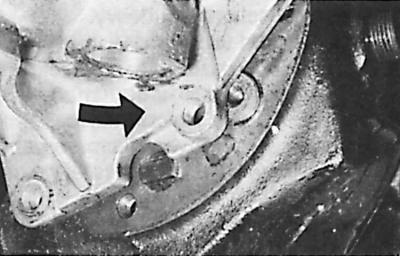

12. Using special tool 16.016, insert the ring into the rear of the crankcase. Check if the oil return port from the rear of the crankcase and the notch in the ring are in line.

13. Fill the O-ring at the rear of the crankcase with grease and insert it with special tool 16.016.

14. Insert the speedometer drive gear and screw on the cover lubricated with sealing paste.

15. Install the locking mechanism plate and secure it with the pin. Insert new plug (covered with sealing paste) behind the front of the gearbox housing.

16. Insert two axles together with the forks, as well as the reverse gear lever. Insert the selector shaft at the rear of the crankcase. Install the ring on the selector axle, as well as its hub.

17. Screw on the selector axis fixing stopper, insert the spring and the plug on the side of the crankcase.

18. Install the cover for the rear of the gearbox housing and fix it in three places around the perimeter of the cover.

19. Install the cover on the front of the gearbox housing.

20. Screw the clutch housing to the front of the gearbox housing (if in this version it appears separately).

21. Remove the gearbox from the work table and insert the release forks and the clutch release bearing into the gearbox housing.

Visitor comments