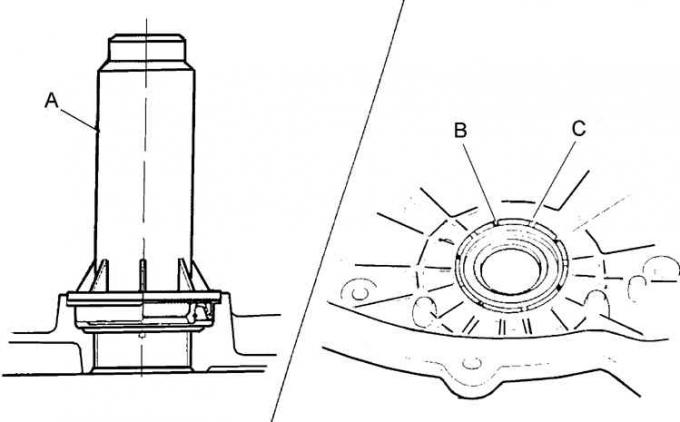

Caulking of the hydrokinetic transmission housing when installing the sealing ring

A - caulking rod, B - traces of factory caulking, C - caulking points of a new sealing ring

Since May 1986, the oil pump O-ring has been fixed by caulking the hydrokinetic transmission housing.

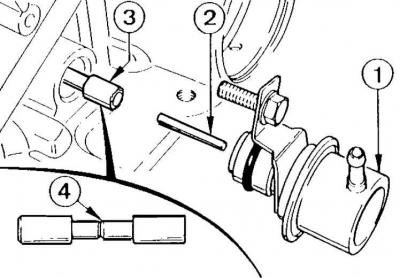

Shift Vacuum Control Assembly

1 - vacuum regulator, 2 - pusher, 3 - valve, 4 - valve identification groove

Since June 1988, a new vacuum shift control valve has been used with the designation: 84 GT 7D 080 BA. It can be identified by the groove in the middle part (4).

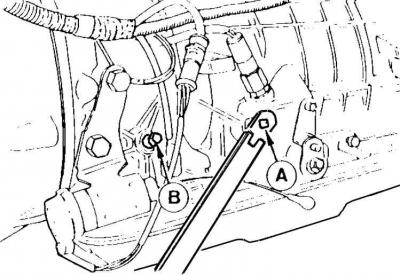

Automatic transmission brake band adjustment bolts

A - a bolt for adjusting the middle brake band,

B - front brake band adjustment bolt

Since August 1988, the method for adjusting the automatic transmission brake bands has changed:

- bolt (A) adjusting the middle brake band must be unscrewed (after complete screwing) 2.5 turns;

- bolt (IN) front brake band adjustment must be unscrewed (after complete screwing) for 2 turns.

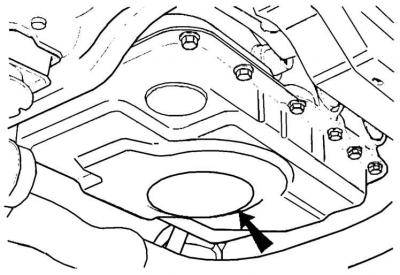

Reshaped automatic transmission oil pan

The arrow indicates the modified shape of the pallet.

Since 1989, automatic transmissions have been fitted with reshaped oil pans and oil pumps with a longer oil receiver.

From the factory code 8 K 24 automatic transmissions have oil pans with a magnet.

Automatic transmission Ford A 4 LD

In April 1989, electro-hydraulic control of the gearbox was introduced with blocking of the hydrokinetic transmission by a system for engaging 3rd and 4th gears.

The blocking of the hydrokinetic transmission clutch is provided by the electronic control device EEC IV. This clutch is released each time the brake pedal is pressed.

The transition from 3rd to 4th gear is provided by an additional solenoid valve controlled by the EEC IV electronic control unit.

The moment of switching from 4th to 3rd gear (transmission reduction) optimized based on vehicle speed, engine load and accelerator pedal position.

After depressing the accelerator pedal all the way (kick-down) the electronic device controlling the automatic transmission causes:

- blocking the hydrokinetic transmission while driving in 3rd gear at a speed of 130 km / h;

- shifting gear from 3rd to 4th at a speed of more than 6100 rpm;

- gear reduction from 4th to 3rd at an engine speed of less than 4200 rpm.

Gear reduction cable adjustment (kick-down mechanism)

1. Switch on the ignition, press the accelerator pedal all the way down and hold it in this position.

2. Turn the automatic transmission kick-down lever fully counterclockwise.

3. Install tool Ford 17.031 on the cable to prevent excessive tension.

4. Loosen the solenoid valve mounting bolts.

5. Move the solenoid valve to the forward position where you feel a lot of resistance.

Attention! If the solenoid valve is moved too far, the cable will be loose. In this case, move the valve back and repeat the previous operations.

6. Tighten the lower mounting bolt to the appropriate torque, then the upper bolt.

7. If the adjustment is correct, the solenoid valve should hold the kick-down lever at a distance of 0.3-0.8 mm clockwise from the end position.

8. If the cable is too tight, the solenoid valve will not reach the correct position and the lever will return to its previous position after passing through the magnet. The cable tension should be re-adjusted.

Other information regarding the technical characteristics, adjustment and repair of an automatic transmission is given in subsection 6.3 (Ford C3 gearbox) and in subsection 3.1.3.15 (transmission Ford A 4 LD).

Visitor comments