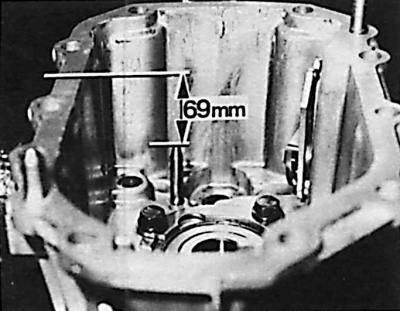

The control dimension of the position of the end face of the selector

Bearing replacement

1. Using an inertial puller, remove the bearing (3) (see fig. Shafts and gears of a mechanical gearbox type MT 75) output shaft from the gearbox housing.

2. Remove the output shaft bearing mounting plate from the gearbox housing.

3. Using a bushing of the appropriate diameter, knock out the ball bearing of the secondary shaft into the gearbox housing.

4. Remove the 1st-2nd gear fork shaft from the gearbox housing.

5. Remove the O-ring from the selector shaft.

6. Using a bushing of the appropriate diameter, remove the selector shaft needle bearing from the gearbox housing.

Attention! In case of replacement of the gearbox housing, position the selector so that the distance between its end face and the plane of the housing (see fig. The control dimension of the position of the end face of the selector) was 69 mm.

7. Using a rod of the appropriate diameter, install a new needle bearing on the selector main shaft from inside the gearbox housing.

8. Install a new O-ring on the main selector shaft in the gearbox housing.

9. Position the selector shaft in the gearbox housing so that its rolled part is directed towards the crankcase sealing plane.

10. Using a suitable pin, press the intermediate shaft needle bearing into the gearbox housing as far as it will go.

11. Using a suitable pin, press the ball bearing of the output shaft into the gearbox housing as far as it will go.

12. In the gearbox housing, install the output shaft bearing mounting plate and tighten the bolts to the appropriate torque.

13. Using a bushing of the appropriate size, remove the ball bearing from the input shaft towards the front of the clutch housing.

14. Remove the needle bearing retaining ring.

15. Using a bushing and a wooden mallet, drive the bearing off the intermediate shaft towards the rear of the clutch housing.

16. Using a puller, remove the selector shaft needle bearing from the clutch housing.

17. Insert the intermediate shaft bearing into the clutch housing using a rod. Do not install the bearing all the way, but leave a distance of 2 mm from the plane of the clutch housing flange.

18. Install a new ball bearing retaining ring.

19. Using a bushing, install a new input shaft bearing into the clutch housing.

Checking the reverse gear axle

1. Remove the reverse gear axle dowel pin using a suitable pin.

2. Remove the bearing support sleeve, reverse idler gear and needle bearing from the axle.

3. Check the status of retrieved items.

4. Slide the needle bearing, reverse idler gear and bearing bush onto the axle.

5. Install new dowel pin.

6. Using a screwdriver, remove the O-ring from the release bearing guide.

7. Install a new sealing ring using a rod of the appropriate diameter; The sealing lip must point towards the shaft.

Primary and secondary shafts

Withdrawal

1. Disconnect the input and output shafts.

2. Remove the 4th gear synchronizer ring and bearing.

3. Remove the 5th gear, synchronizer ring and needle bearing from the output shaft.

4. From the other end of the output shaft, remove the 3-4 gear synchronizer set spring ring.

|  |

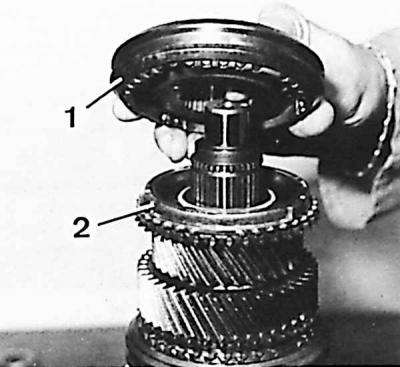

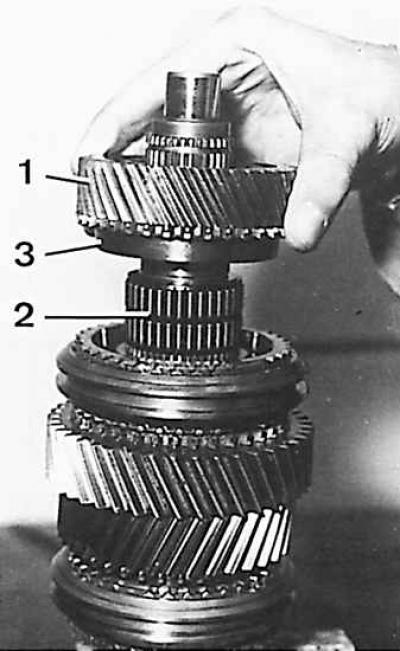

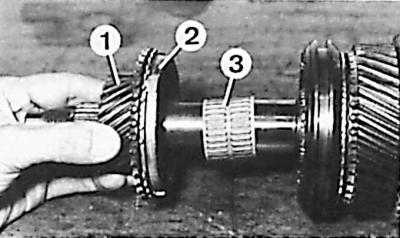

5. Remove the assembly from the output shaft: synchronizer (1) 3rd–4th gear, ring (2) 3rd gear synchronizer, pinion (3) 3rd gear and needle bearing (4).

Attention! Synchronizers should not be disassembled to maintain the correct position of all their parts.

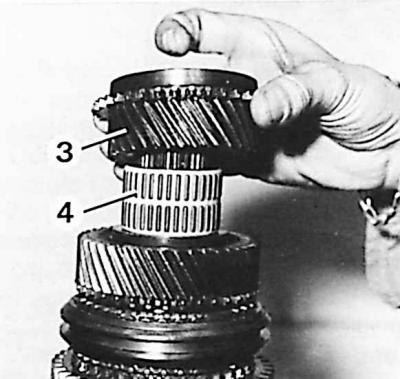

6. Remove gear from output shaft (1) 2nd gear, needle bearing (2) and 2nd gear synchronizer ring (3).

7. Rotate the output shaft and remove the 5th and reverse synchronizer set spring.

8. Remove gears from output shaft (1) 5th gear, synchronizer rings (2) 5th gear and needle bearing (3).

Examination

1. The teeth of the gears and synchronizers must not be chipped or excessively worn, and the surfaces of the teeth must not show signs of scuffing.

2. It should be checked whether the synchronizer hubs are chipped and whether they move without excessive clearances and jamming.

3. The needle bearing should be replaced if there are obvious scratches on the surface, or if there are excessive clearances or signs of wear.

Assembly

Attention! Synchronizers 1-2 gears and 5th and reverse gears are identical, but they must not be interchanged when assembling the gearbox. When assembling, lubricate all elements, especially the synchronizer rings and the needle bearing with the oil used for the gearbox.

1. Install the needle bearing and reverse gear onto the output shaft.

2. Install the synchronizer ring and the 5th and reverse gear synchronizer.

3. Install a new set spring ring.

4. Rotate output shaft and install needle bearing and 1st gear.

5. Install the 1st synchro ring, 1st-2nd synchro, and a new set circlip.

6. Install the 1st synchronizer ring, needle bearing and 2nd gear.

7. Heat 3rd gear needle bearing ring to 100°C.

8. Slide the hot ring onto the output shaft.

Attention! The needle bearing ring must be inserted as far as it will go. A new needle bearing must be used during installation.

9. After the ring has cooled, install the needle bearing and 3rd gear.

10. Insert the 3-4 gear synchronizer assembly (shorter side up) and a new set spring ring.

11. Rotate the shaft and install the 5th synchronizer ring, needle bearing and 5th gear.

12. Install 4th gear synchronizer ring and bearing.

13. Connect the secondary and primary shafts.

14. Lower bolts securing the clutch housing to the cylinder block.

Visitor comments