Take out pushers with adjusting washers. Pushers should be stored in such a way that during assembly they fall into the same places from which they were removed during dismantling.

Compress the valve springs with special pliers so that you can remove the lock cotters. Remove the rest of the parts related to the valve subassemblies from the block head.

Remove the vacuum pump drive pusher.

Remove the two engine lifting hooks located on the head of the block.

Remove the oil pressure sensor and disconnect the cooling system hoses.

Remove the valve stem seals and remove the valve spring caps.

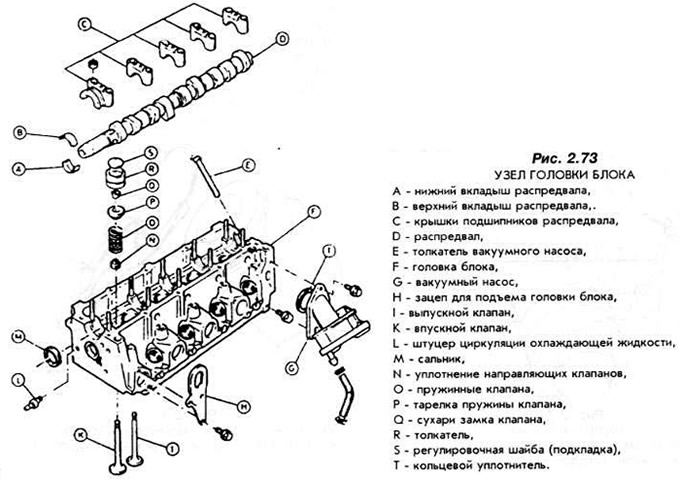

The parts related to the block head assembly are shown in fig. 2.73.

Checking and repairing the block head is carried out in exactly the same way as previously described in the subsection on checking and repairing the 1.4i / 1.6i gasoline engine block head.

The prechamber can project up to 0.06 mm above the seating surface of the block head.

The block head is assembled in the reverse order. The intake valve clearances are 0.30 mm. graduation - 0.50 mm. Matching washers (lining) are included in the spare parts kits. To adjust the valve clearance, the cam is mounted vertically above the tappet.

The gap is measured with a feeler gauge and the results are recorded. Turn the camshaft 1/8 of a turn and use tool 21-106 to press the tappet down. With this installation, the pusher adjusting washer can be replaced. Adjusting washers are marked on the bottom (on the surface adjacent to the pusher). To replace it is necessary to use new washers, laying them on dry pushers.

Note: block head seating surface (in contact with the head gasket) cannot be machined.

Visitor comments