General information

Due to differences in design, the repair of plastic elements involves different repair methods:

- Thermoplastic dressing

- Plastic welding (PC, PP/EPDM, etc.)

- Plastic bonding (all plastic parts)

- Plastic lamination (only GRP elements with polyester resin)

When performing repairs, the characteristics of the plastic are of great importance. Two main groups can be distinguished:

- thermoplastics (plastomers or thermoplastics)

- duroplasty (thermoset plastic)

Thermoplastics (plastomers)

- Heat causes thermoplastics to change from a solid state to a thermoelastic state and then to a thermoplastic state.

- After the thermoplastics are cooled, they return to a solid state.

Duroplasty

Duroplastics are much heavier and more brittle than thermoplastics.

- When heated, their strength remains largely unchanged.

- When the critical temperature is exceeded, duroplastics are destroyed.

- Cooling will not return them to their original state.

Plastics used by Ford

| Abbreviation | Name |

| ABS. | Acrylonitrile butadiene styrene (polymer) |

| PA | Polyamide |

| PC | Polycarbonate |

| PP | Polypropylene |

| PP/EPDM | Polypropylene / ethylene propylene rubber |

| PC/PBT | Polycarbonate/polybutylene terephthalate |

| PBT/PC | Polybutylene terephthalate / polycarbonate |

| PUR | Polyurethane |

| GF | fiberglass reinforced |

Plastic identification

If the plastic does not have any marking, its type can be determined using two different procedures/techniques:

- visual inspection

- Mechanical check

Identification of the type of plastic is required to perform plastic welding in order to determine the correct use of the appropriate welding electrode.

Visual inspection

Visual inspections mainly serve to identify PUR and GRP materials. Thermoplastic elements (e.g. bumpers) often stained and therefore their identification is difficult.

Identification characteristics:

- PUR: If cracks form or similar damage occurs, visible pores in the foam.

- GRP: recognizable fiberglass structure on the inside.

Mechanical check

- Degree of hardness; the higher the tone, the harder the plastic.

- Elasticity (elasticity); the more subdued the tone, the higher the elasticity of the plastic.

NOTE: Mechanical checks may identify the plastic group, but not the type of plastic.

In accordance with the statistics of damage, plastic bumpers are most often repaired.

NOTE: If polyurethane (foam) bonded to the outer shell of the bumper on the inside, this PUR foam should not be removed for repairs. If there is severe damage such as cracking or splitting of the outer shell, do not make any repairs to the foam area. The rule for this case is: replace the element.

The outer shell of plastic bumpers mainly consists of thermoplastic materials. Depending on the extent of damage and accessibility, the following repair procedures can be applied:

- Thermoelastic dressing

- Gluing

- Welding

Thermoelastic dressing

Bumpers often have deformations that occur in the elastic zone. They usually take the form of dents, indentations, and bends. Many of these deformations (e.g. in the bumper) either immediately or after some time disappear. This self-repair depends on the extent of the damage and the temperature. Most plane deformations in the elastic zone are eliminated (the shape of the element returns to its original shape) when heated with a jet of hot air (technical hot air gun).

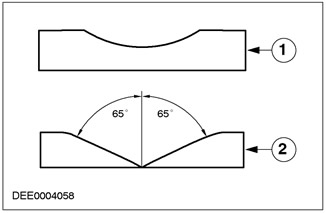

Elastic deformations of planes

NOTE: Required exposure to heat depends on the type of plastic. Heating should not be carried out outside the elastic zone. Plastic deformation cannot be reversed. Never use open fire!

Indentations or indentations in the plane should be heated evenly to approximately 200°C using a technical hot air gun and, if possible, applying heat alternately from both sides. If you do not overdo it with heat, the deformation will be eliminated and the surface of the element will return to its original shape.

To a certain extent, dressing can be supported using mechanical tools such as a hammer handle, a plastic wedge, etc.

Extended cracks and twisting

If there are extended cracks or even twisting in the damage zone, the possibilities of thermoelastic straightening are limited. For this type of damage, repair by gluing is most suitable.

- To prevent tension in the material, cut off cracked or twisted areas (using a hacksaw).

- Heat the notch to approximately 200°C (evenly, inside and out) and correct the shape to its original shape using a narrow spatula or hammer handle.

Plastic welding

NOTE: Do not weld plastic in the foam area.

Plastic welding is the most suitable way to repair cracks in plastic bumpers where the back of the damaged area is not suitable for bonding repair. Examples: Ribbed section, box section, narrow rounded sections in reinforced areas.

Required tools and materials

In addition to the tools available at the service station (such as scrapers, grinders, etc.) The following tools are required for plastic welding:

- Technical hot air gun (approximately 1500 W)

- welding nozzles

- Various welding electrodes

- Milling cutter W 5.5 mm for welding grooves.

- Heart-shaped scraper.

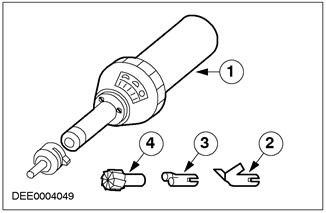

Plastic Welding Gun

| Pos. | Spare Part No | Name |

| 1 | - | Plastic Welding Gun |

| 2 | - | Nozzle for fast welding |

| 3 | - | wedge nozzle (fixed nozzle) |

| 4 | - | end mill |

Preparation of the repair site (crack)

Prepare the crack site for V-groove welding.

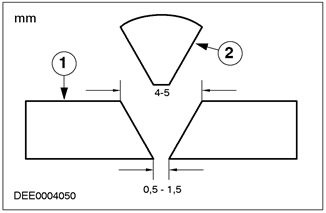

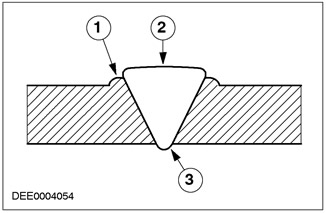

Welded seam with V-shaped cutting edges

| Pos. | Spare Part No | Name |

| 1 | - | Part to be repaired |

| 2 | - | welding filler (certain form) |

Preparing a V-Groove Weld:

- Make a groove for welding using a scraper (end mill).

- Maintain a connection angle of 60°- 70°.

NOTE: Drill out the end of the crack (drill with a diameter of 3 mm), which prevents further cracking. Before starting welding in a place where the alignment of the edges is uneven, fix the beginning of the crack using pliers.

- Drill out the end of the crack.

Preparation of technical hot air gun and welding electrode

Convert a hot air gun into a plastic welding gun (extended nozzle and fast welding nozzle).

Adjust welding temperature (200°C -700°C) in accordance with the prescribed values.

Welding temperature

Welding temperature is determined by two factors:

- Plastic type

- Welding electrode thickness

Values for the most important materials and the thickness of a conventional welding electrode (5.7mm x 3.7mm)

|

Thermoplastic |

Welding temperature in °C ( prescribed value) |

Setting the control potentiometer for the plastic welding gun |

|

|

Wedge nozzle |

5.7mm Fast Welding Nozzle |

||

|

ABS. |

350 |

4,5 |

5,3 |

|

PP |

300 |

3,8 |

4,5 |

|

PP/EPDM |

300 |

3,8 |

4,5 |

|

PBT/PC |

300 |

3,8 |

4,5 |

|

PA |

400 |

5,1 |

5,6 |

|

PC |

350 |

4,5 |

5,3 |

|

PC/PBTP |

350 |

4,5 |

5,3 |

- Weld PBT/PC plastic using only PP welding electrode.

- Glass fiber reinforced plastic cannot be welded.

- Ford Ka blue painted plastic components cannot be painted and are therefore not suitable for repairing plastic components.

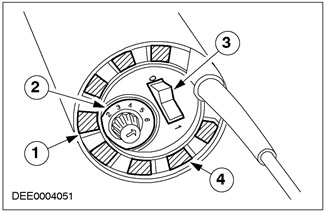

Rear side of the plastic welding gun

| Pos. | Spare Part No | Name |

| 1 | - | Air intake hole |

| 2 | - | Temperature control unit |

| 3 | - | Switch |

| 4 | - | Air flow switch |

- These temperatures are the air temperature for the plastic welding gun. The temperature of the material is much lower.

- Follow the manufacturer's instructions when adjusting the temperature.

- Preliminarily, within 3-4 minutes, warm up the welding equipment to the desired welding temperature.

- Make a front bevel on the welding electrode to ensure gradual filling at the beginning of the groove (cracks).

Welding

When welding plastic, the following requirements must be observed:

- The correct temperature

- Welding speed uniformity

- Working pressure uniformity

Insert the beveled welding electrode into the heated pre-heating chamber of the fast welding nozzle until the tip of the welding electrode emerges from the back.

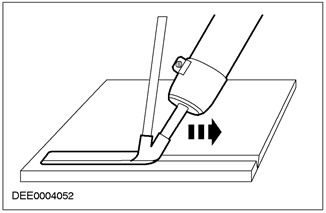

Aligning the Fast Welding Nozzle

The reverse side of the fast welding nozzle should be parallel to the surface to be repaired in the longitudinal direction. Parallel arrangement in the longitudinal direction is achieved by appropriately tilting the welding equipment.

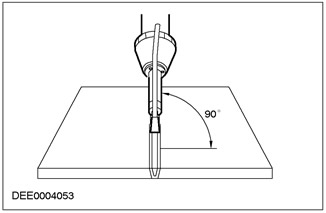

Position of the plastic welding gun

- Move the gun for plastic welding in such a way that the welding electrode is located exactly vertically in relation to the groove.

- The welding procedure can be started when the welding electrode and the plastic to be welded are in a plastic state.

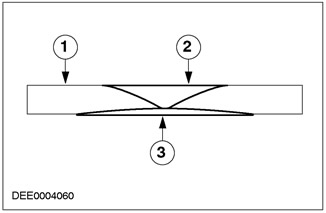

Weld seam

| Pos. | Spare Part No | Name |

| 1 | - | Weld bead |

| 2 | - | Reinforcement of the weld |

| 3 | - | Weld base |

NOTE: Optimum bonding is achieved when a small and even weld bead forms along the edge of the weld. It is very important to weld the crack through. Check the weld seam on the reverse side and repeat welding if necessary.

The working pressure during welding is applied only to the welding electrode.

Welding errors

Deformation:

- The repair area was overheated.

- The presence of tension in the material when welding parts.

- The plastic element is too thin.

Bad weld:

- Too low welding temperature.

- Too high welding speed.

- Welding of various materials.

Weld seam buried:

- Groove too wide along the crack

- Too high welding temperature.

Finishing the weld

- After cooling, the bulge of the weld can be removed using an angle grinder and P80 grit sandpaper.

- Then flat sanding is carried out using a hand sander and P120 - P220 grit sandpaper.

- Clean the machined repaired surface using a plastic cleaning solution.

- Apply a thin layer of plastic primer to the repaired surface.

Reciprocating plastic welding

Reciprocating plastic welding is the preferred method for repairing cracks in hard to reach areas.

- In reciprocating welding, the welding electrode moves freely.

- Groove preparation along a crack is similar.

Welding

- The plastic welding gun is only equipped with an extension nozzle.

- The welding electrode and the groove along the crack come into a plastic state by means of vertical reciprocating movements.

- The welding electrode in the plastic state is vertically inserted into the groove.

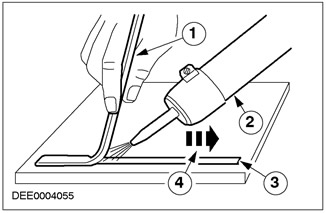

Reciprocating welding

| Pos. | Spare Part No | Name |

| 1 | - | welding electrode |

| 2 | - | Plastic Welding Gun |

| 3 | - | welding groove |

| 4 | - | Direction of welding |

The following requirements must be observed when performing reciprocating welding:

- Uniform heating of the welding electrode and welding groove.

- Uniform welding speed.

- Vertical arrangement and uniform pressure on the welding electrode.

All other repair actions are described in Chap. «Plastic Welding - Weld Finishing».

Plastic bonding

General information

Gluing technology has some advantages over welding technology:

- Within the thermoplastic elastomer group, all semi-rigid auxiliaries (such as bumpers, front grilles, etc.) can be repaired without identification.

- For all thermoplastic elements, a two-component, polyurethane-based adhesive should be used.

- To ensure the original mechanical properties, to the grooves (on cracks, up to a maximum of 100 mm) and kinks, reinforcing tapes can be attached.

Required tools and equipment

To perform bonding of thermoplastic elements, tools and equipment from the paint shop can be used. To clean cracks and scratches, you can use angle grinders and belt grinders. For fine grinding, hand-held surface grinders with suction are used. The infrared heater guarantees fast and effective drying.

Repair kit for plastic parts

- Plastic cleaning solution

- plastic primer

- Adhesive repair kit

- Three double cartridges

- Three emulsion tubes

- Metal reinforcing tapes

- amplifying fiber

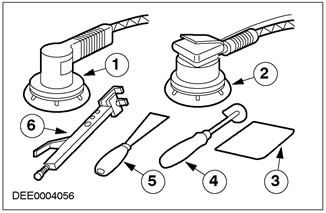

Tools and accessories

| Pos. | Spare Part No | Name |

| 1 | - | Angle grinder with speed change |

| 2 | - | Surface grinder |

| 3 | - | Plastic putty |

| 4 | - | Scraper |

| 5 | - | Spatula for paint |

| 6 | - | pliers |

Preparation of the repair site (scratches)

Before repair, clean the plastic parts on both sides using a high pressure cleaning solution and then dry.

Clean the surface to be repaired using a plastic cleaning solution.

Sanding a scratch

| Pos. | Spare Part No | Name |

| 1 | - | Scratch preparation |

| 2 | - | Crack preparation |

- Grinding scratches should be carefully, ensuring the plane and using a hand-held surface grinder. Sandpaper, grit P80 - P120

- Fine sanding with hand sander: sandpaper, grit P120

NOTE: Wear protective gloves when cleaning. Thoroughly clean the repair area using a plastic cleaner and paper towels.

- Spray the plastic primer evenly over the repair area.

Preparation of the repair site (cracks)

- Sand the crack on the front so that it is flat using an angle grinder or a belt grinder. Grinding surface 40-60 mm wide

- Sand with a hand sander. Sandpaper: grit P120.

- Ream end of crack (diameter 3 mm), to prevent further cracking.

- Wipe the reverse side along the crack.

- Clean the repair area on both sides using a plastic cleaner and paper towels.

- Spray the plastic primer evenly over the repair area.

Bonding preparation

- The two-component adhesive is applied to the cleaned and primed repair area using a hand gun.

- Actuating the gun lever forces the resin and hardener from the dual cartridge into the attached emulsion tube.

Bonding crack

Even minor depressions such as cracks require preparation. To ensure sufficient priming for the use of the adhesive, the area to be repaired must also be surface treated. It also prevents the repair area from subsequent settling.

- After cleaning and priming with excess, fill the scratch cavity with adhesive.

- During the application process, the end of the emulsion tube must be dipped into the adhesive to prevent air from entering.

- Spread and level the adhesive using a flexible plastic spatula.

- Practice the adhesive curing procedure using an infrared heater or drying oven.

Bonding a crack using reinforcement

The repair site is reinforced to increase torsional resistance in case of cracking and rupture of great extent. For this purpose, appropriate reinforcing materials are fixed on the back side (metal strips, reinforcing fibers).

- Close the crack on the front side with PE sheet and adhesive tape.

- On the back side, fill the groove made along the crack with plastic glue.

- A wide band of reinforcing fiber is fixed over the groove in the adhesive bead.

- The ends of the crack are strengthened by securing a metal strip, which is attached to the plastic element using pliers.

- Then level the reinforcing material over the entire surface.

- Dry using an infrared heater or drying oven.

- The PE sheet prevents excess adhesive from the front of the crack.

- Remove the PE sheet after the glue has dried.

- Smear the adhesive over the repair area on the front side.

- Work through the curing procedure using an infrared heater or drying oven.

- Cool the adhesive to room temperature to prevent the adhesive from peeling off when sanding and to prevent wear on the sandpaper.

Grinding

NOTE: If dry sanding, use suction and dust mask.

- Sand off the exposed adhesive using a hand sander. Sandpaper: grit P120 - P220.

- Manually refine skews and curved sections.

- Use an abrasive pad to roughen painted surfaces.

- Thoroughly clean the plastic element using plastic cleaner and paper towels.

NOTE: Dry the plastic primer thoroughly (matte coating).

- Spray a thin layer of plastic primer on the repair area and sanded areas for subsequent application of 2K putty.

Application of two-component putty

To prevent the occurrence of porosity at the edges and to smooth out irregularities, it is advisable to apply a 2K putty (MS, HS) with an additive that increases elasticity.

- After drying, cool the 2K putty to room temperature and sand using a hand sander and fine sandpaper.

- Manually (wet way) refine skews and curved areas using fine-grained sandpaper.

- Check the relief of the repair site and correct if the relief is uneven.

- Carry out staining according to the manufacturer's instructions.

GRP repairs

General information

GRP material is hard and brittle in its mechanical properties. Due to these mechanical properties, cracks and breaks often result in serious damage. The stability and safety of GRP elements is degraded if the glass fiber reinforcement cracks. In the event of serious damage that affects the design of the element, such elements should be replaced. minor damage (type of abrasion, cracks up to 80 mm, holes up to approximately 60 mm in diameter, etc.) can be repaired in accordance with technical and appearance standards, provided that the damage is not located in heavily used or hard-to-reach places. To ensure excellent repair quality, observe the following points:

- Room temperature should be at least 15°C and the air should be as dry as possible.

NOTE: Fingerprints remain on the film preventing a proper connection.

- The repair site must be thoroughly dried and cleaned.

- Before repair, the GRP element to be repaired must be dried using an infrared heater or drying oven.

- In case of large cracks and breaks, the strength of the outer shell can be restored by using reinforcing material on the reverse side.

Required Tools and Accessories

- Hacksaw (bodywork saw) to separate cracks.

- Axial grinder, angle grinder or belt grinder for grinding the repair area.

- Surface grinder for grinding and polishing the repair surface.

- Hand sander for sanding small surfaces.

Repair site sanding

- Finish the edge of the hole into a V-shaped and flat shape using an angle grinder and P80 - P120 grit sandpaper.

- Remove layers of putty and paint.

- If cracks have formed, they are polished at the base of the crack by 3 mm. This eliminates any internal stress.

- Careful, flat grinding is essential to ensure subsequent adhesion of the repair material.

NOTE: The surface must be sanded by hand.

- Grinding with an angle grinder is accompanied by the release of heat, which causes a change in the surface structure of the resin. This leads to poor adhesion.

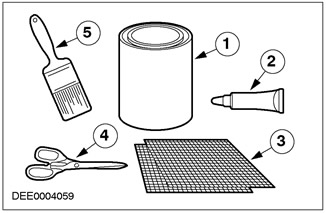

GRP Repair Components

| Pos. | Spare Part No | Name |

| 1 | - | polyester resin |

| 2 | - | Hardener |

| 3 | - | Fiberglass mats |

| 4 | - | Scissors |

| 5 | - | Brush |

Application of polyester resin

The polyester resin is mixed with a hardener and, using a brush, a thin layer is applied to the clean repair area.

Insert fiberglass mat

- Cut the fiberglass mat to the required size and insert it into the polyester resin to be applied.

- Apply more polyester resin over the fiberglass mat and add a second or third mat if necessary.

NOTE: Completely immerse the fiberglass mat in the polyester resin. Air cannot be present in the repair area.

- Apply polyester resin using a brush.

- Let the polyester resin dry at room temperature.

- From the back, reinforce large cracks and tears with reinforcing material to restore the strength of the outer shell.

Putty application

- The depressions on the front side are filled with polyester filler to provide a smooth, flat surface.

- Repeat if necessary.

Apply putty

| Pos. | Spare Part No | Name |

| 1 | - | Repairable GRP element |

| 2 | - | Polyester putty |

| 3 | - | fiberglass insert |

Final putty application

Restore the surface relief by applying a polyester putty.

Sanding with a hand sander

- Remove the protruding polyester material using a hand sander. Sandpaper grit P120 - P220.

- The repaired surface can be painted after sanding.

Precautionary measures

- Polyester resin, adhesives, solvents and thinners are flammable and should be kept away from open flames or flames.

- Cutting and grinding operations should only be carried out in rooms equipped with exhaust ventilation (suckers).

- If rooms with suction systems are not available, use only tools with suction systems.

- The use of protective equipment such as gloves, goggles, aprons and respirators is very important.

See Section 501-25A / 501-25B / 501-25C / 501-25D / 501-25E / 501-25F / 501-25G for more information. It is also important to follow all relevant regulations, health and safety laws, information sheets, safety notices, and recommendations for handling adhesives containing isocyanate ester, polyester resin, solvents, and thinners.

Visitor comments