Introduction

This chapter gives a brief overview of how noise, vibration and harshness parameters (NVH) appear in the vehicle and what corrective measures are possible.

What is meant by the term NVH in the automotive industry

- N = Noise - Sound can be heard

- V = Vibration - Vibration, can be felt

- H = Rigidity, its effect can be heard and felt

Types of noise in NVH technology

- Noises in cars are classified according to their tone:

- Low pitch - roar, buzz

- Medium tonality - buzzing, crackling

- High pitch - howl, whistle, squeak

- Loud howls and whistles hurt the ears.

How various noise enters the car:

- Low-pitched noise is mainly produced by the engine.

- Low-pitched noise is also caused by the road surface, especially if the road surface is uneven. This is the form (a hum that can be felt by people in the car as a vibration.

- However, high-pitched noise that is perceived as howling or whistling is often airflow noise (wind noise) or comes from items such as an alternator, power steering pump, or drive belt.

- There is also a rattling noise that can occur when driving on rough roads. «twitching» noises are produced, for example, by shock absorbers, chassis elements or loose elements inside the vehicle.

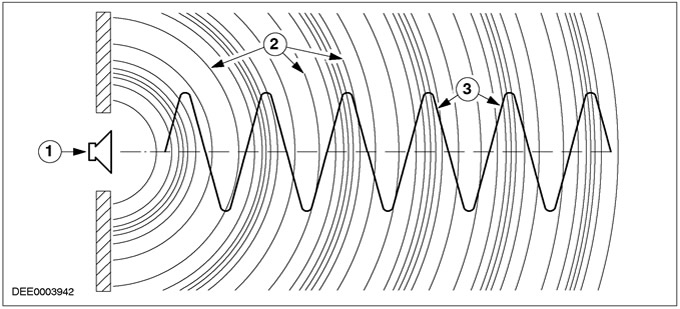

Propagation of sound waves in air

| Pos. | Spare Part No | Name |

| 1 | - | Sound source such as engine |

| 2 | - | Sound wave |

| 3 | - | Amplitude |

Sound is the propagation of longitudinal waves in the form of pressure changes in the air.

Sound transmission through the body

Sound is transmitted by liquids or solids, such as the body of a car.

Transmission speed (sound speed) in liquids or solids depends on the material, but generally faster than the speed in air (about 5 times faster).

Combination of transmission by air and solids

NOTE: The transmission of sound through air and solids is of prime importance in automotive technology.

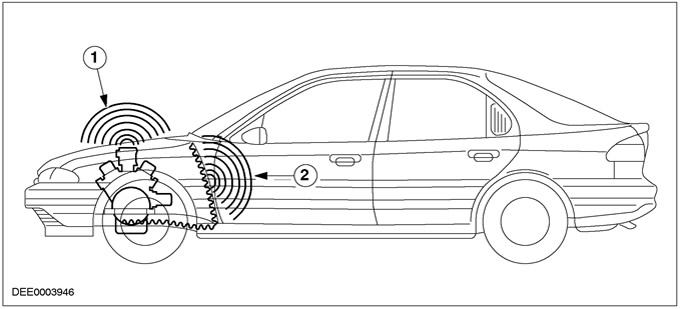

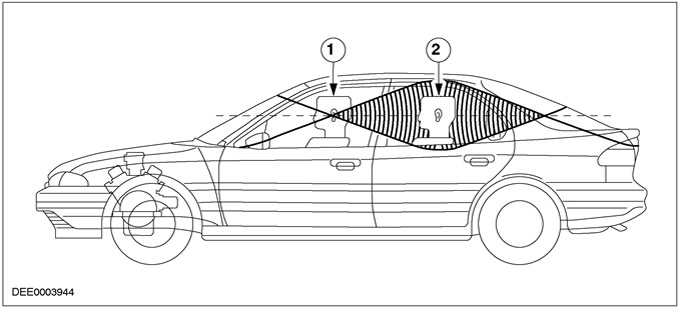

Noise transmission in the car

| Pos. | Spare Part No | Name |

| 1 | - | The passage of sound through air |

| 2 | - | Sound vibrations |

Example:

- The source of the noise is the engine. Engine Noises:

- go straight through the air

- transmitted as vibrations from the engine to the body and «radiated» into the car interior by air, for example, by a partition.

vibrations

- Frequencies below 20 Hz (low frequencies) and exceeding 20 kHz (high frequencies) are not perceived by the human ear.

- The engine is installed in such a way that, due to the roughness of the road, it oscillates vertically on its elastic supports.

- Untuned engine mounts will transmit vibrations to the bodywork and therefore to the occupants of the vehicle.

- The following basic rules apply:

- In the automotive industry, not only audio frequencies must be considered, but also inaudible (low) frequencies.

- Low frequency vibrations can usually be seen (large amplitudes).

- High-frequency vibrations can be heard, but they will also be perceived as vibrations of the floor, steering wheel or seat.

Resonance

- Each body has its own vibration frequency.

- If a vibrating system is excited at its own frequency of vibration, it will begin to resonate.

- Rough running of the motor manifests itself, for example, when the resonant frequency is reached (critical engine speed).

- After increasing the engine speed above this value, the engine starts to run smoothly again very soon.

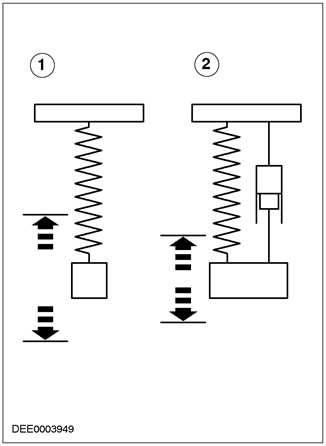

Damping

- If the damper is mounted parallel to the spring, the damping characteristic is designed to reduce body movement.

- The shock absorber on the car also works.

- Damping affects the resonance of an object or system.

- The moving mass is damped by a properly functioning shock absorber, thus immediately stopping the oscillation of the body.

- A shock absorber in a car is a damper (vibration damper), which allows the body to oscillate with gradual damping of vibrations.

Hesitation

| Pos. | Spare Part No | Name |

| 1 | - | Continuous oscillation (undamped) |

| 2 | - | damped oscillation |

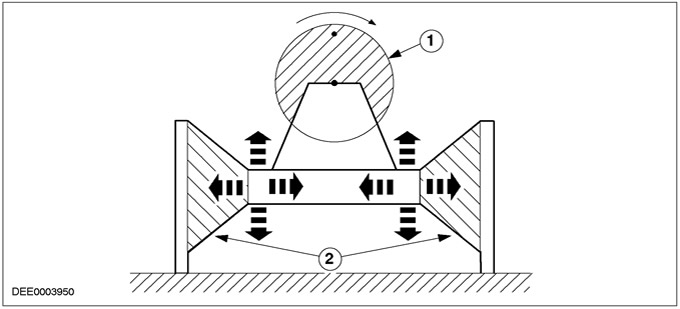

Insulation

In oscillation technology, the term «insulation» means separation of elements and systems. Example:

- The engine is mounted on spring elements so that as little vibrations as possible are transmitted to the car.

- In the automotive industry, rubber pads are almost always used as insulation (support). The elasticity of rubber acts like a spring.

- The effectiveness of this type of separation depends on the design of the element.

Directional loading of the rubber cushion to provide optimum insulation

| Pos. | Spare Part No | Name |

| 1 | - | Engine |

| 2 | - | engine support |

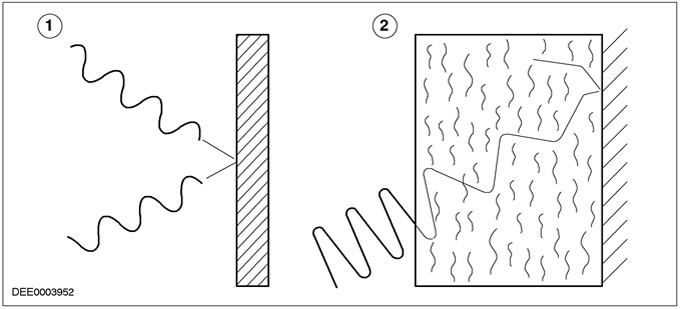

Absorption

- Sound waves bounce off solid surfaces

- If they encounter soft surfaces, they are absorbed. Both the material and the thickness of the material play an important role here.

| Pos. | Spare Part No | Name |

| 1 | - | Reflection of sound waves |

| 2 | - | Sound wave absorption |

Example:

- All sound insulation elements such as door trim, floor mats, headlining, storage shelves and seats are removed from the vehicle.

- The result of this is that the sound is reflected directly (sound level rises), and the effect of a concert hall is created.

The nature of noise and vibrations in the car

Vehicle occupants perceive sounds or noises at different levels depending on where they are.

Sound/noise wave (standing wave) in the car

| Pos. | Spare Part No | Name |

| 1 | - | The driver is in «dead zone» |

| 2 | - | The rear passenger is in the area «wave shaft» |

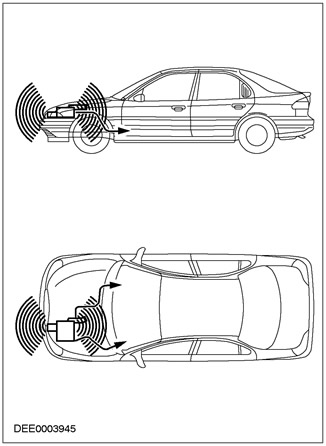

The nature of noise and fluctuations in intake and exhaust systems

Vehicle intake system as a source of airborne sound and solid body sound

Vehicle exhaust system as a source of airborne sound and solid body sound

The ways in which sound is transmitted

- The top drawing shows the paths that sound can take from intake and exhaust systems.

- In addition to airborne sound, solid-borne sound predominates in both systems. To keep this ratio as small as possible, this type of oscillating element needs to be connected to the body using rigid connections.

- The exhaust system is a particularly oscillating element and requires optimal insulation by connecting it to the floor, as well as good wiring and mounting points to reduce solid body sound transmission.

Intake system

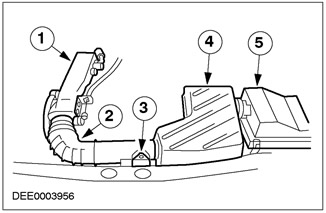

| Pos. | Spare Part No | Name |

| 1 | - | Intake manifold |

| 2 | - | Connecting hose |

| 3 | - | fixing element (fixing with rubber) |

| 4 | - | Air filter |

| 5 | - | Resonator |

- The volume and length of the intake systems match exactly. No changes can be made during maintenance or repair. When connecting elements (hoses and pipelines) pay attention to the airtightness of all connections.

- The surfaces of all elements subject to large changes in pressure in the intake system are particularly subject to strong fluctuations.

- Temperature influences, such as heating of the air filter housing, can cause changes in the hardness of surfaces.

- To prevent the transmission of sound caused by vibrations of the surface of the intake system to the vehicle body, during maintenance, the following points should be considered:

- The entire intake system must be isolated from the body and fixed in rubber bushings without any stress.

- The air ducts of the intake system must not come into contact with body parts.

- Plug-in foam insulation at the point of contact with the body or other elements.

Exhaust system design

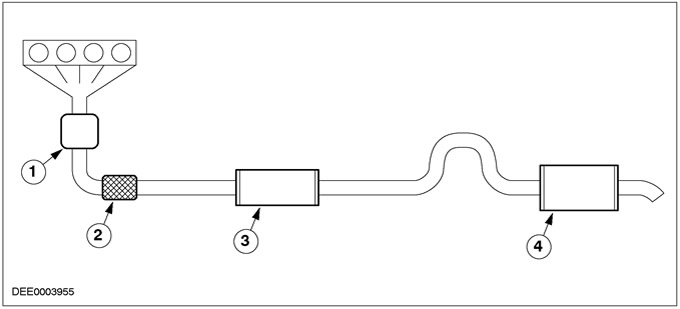

| Pos. | Spare Part No | Name |

| 1 | - | catalytic converter |

| 2 | - | Separating element |

| 3 | - | Front muffler |

| 4 | - | Rear silencer |

- Exhaust systems must be installed without any deformation.

NOTE: The rubber pads that the exhaust system is suspended in also transmit vibrations, and under some conditions can also cause noise problems. For this reason, it is important that the exhaust system is installed without deformation.

- Rubber pads should not be «stretched out».

- Exhaust manifold and catalytic converter (if installed directly on the engine) must be hardwired to the motor (without connectors in brackets).

- Simple problem check:

- Remove all supports on which the exhaust system is suspended.

- Hang the release system with cords in two places, maximum.

- Check the noise level inside the vehicle during a road test.

- If this resolves the problem, the exhaust system mounts are the cause of the noise.

- Reinstall the exhaust system mounts, one at a time, and road test the vehicle after installing each.

- Continuing in this way step by step, you can find the support that causes noise in the car interior.

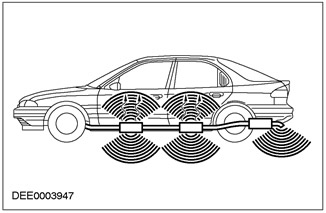

Body assembly

Purpose

- Various requirements are placed on the car body, especially when the car is moving. The predominant vibrations are caused mainly by other elements of the vehicle, such as the engine and mounts. Therefore, the body is one of the most important elements of the car in terms of NVH.

- The described elements of the car, in accordance with their functions, were individual independent sources of noise. But the body connects and accommodates all the elements of the car.

- The body is subjected to vibration from sound carried through the air and carried by solids.

- The body assembly must absorb all vibrations and impulses from all elements and, if possible, not transmit them to the vehicle interior.

- The largest NVH parameters on the body are characterized by steel panels of the roof, sidewalls and floor. They are strongly stimulated by the body structure and act like a loudspeaker transmitting noise.

Additional body requirements

- Good crash behavior

- Large interior space

- Corrosion resistance

- small mass

- Good aerodynamic shape

Between these points, a compromise must be made. One example is between high body rigidity for good NVH performance and good crash energy absorption through the use of deformable zones.

Example:

- Waterproof does not mean soundproof, so the following points should be taken into account:

- Proper window installation.

- Correct installation of seals.

- Additional points

- Holes in the engine compartment

- Door and window seals

- Heater and ventilation openings

- Sunroof drain hoses

- Body spars and cross members are often sound transmission channels. Possible corrective measures:

- Installation of partitions in critical places, such as the joints between the spar and the pillar «A», to provide good sound insulation for airborne sound.

- Installation of foam plugs in problem areas.

- Filling hollow sections with foam.

NOTE: Styrofoam and foam cores are used in vehicle manufacturing to seal airborne sound transmission points. If the problem is wind, tires, engine or road noise, check the position of the foam elements.

Visitor comments