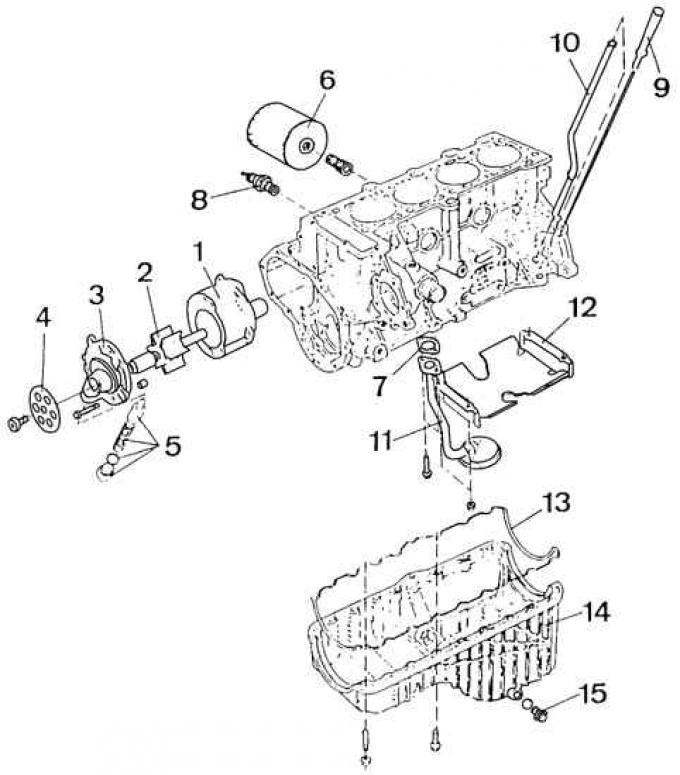

DOHC engine lubrication system

1 - oil pump housing, 2 - oil pump propeller shaft with rotor, 3 - oil pump cover, 4 - oil pump sprocket, 5 - bypass valve, 6 - oil filter, 7 - gasket, 8 - oil pressure sensor, 9 - pointer oil level, 10 - oil level indicator guide, 11 - oil supply pipeline with oil receiver, 12 - oil pan baffle (oil deflector), 13 - oil pan gasket, 14 - oil pan, 15 - oil drain plug

Oil pressure check

1. Warm up the engine to normal operating temperature.

2. Unscrew the oil pressure sensor.

3. Screw the manometer fitting in its place.

4. Start the engine and check the oil pressure at idle and at 2000 rpm. Compare the obtained values with the required values (see section 3.1.4.3.1.5).

5. Disconnect the pressure gauge.

6. Screw in the oil pressure sensor.

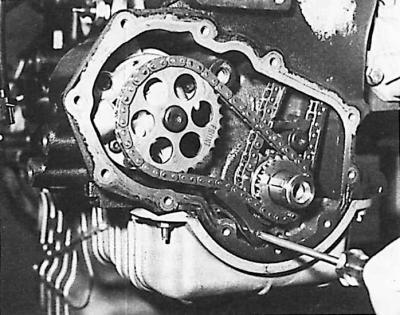

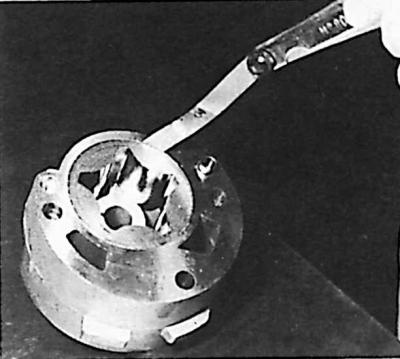

Unscrewing the bolt of the tensioner of the cardan chain of the oil pump of the DOHC engine

Removing the oil pump

1. Disconnect ground wire from battery.

2. Remove the alternator drive and coolant pump V-belt.

3. Unscrew the bolt securing the pulley to the crankshaft.

4. Using a puller, remove the pulley from the crankshaft.

5. Remove the lower casing of the propeller chain of the gas distribution system.

6. Remove the oil pump propeller chain tensioner.

7. Remove the sprocket and chain from the oil pump shaft.

8. Unscrew the Torx bolts securing the oil pump.

9. Remove oil pump.

Oil pump installation

1. Check the condition and, if necessary, replace the oil pump gasket.

2. Install oil pump with gasket.

3. Tighten the oil pump Torx bolts.

4. Rotate the pump shaft several times to suck in the oil.

5. Put on the oil pump sprocket (inscription "FRONT" on the sprocket must be visible from the front of the engine) along with the propeller chain of the pump.

6. Tighten the torx bolt securing the sprocket to the pump shaft.

7. Install the oil pump propeller chain tensioner.

8. Screw with the installed new gasket the lower casing of the cardan chain of the gas distribution system.

9. Put the pulley on the crankshaft.

10. Tighten the crankshaft pulley bolt.

11. Put on the alternator and coolant pump drive V-belt and adjust its tension.

Oil pump check

1. Remove oil pump.

2. Unscrew the Torx bolts securing the oil pump cover.

3. Remove the oil pump cover.

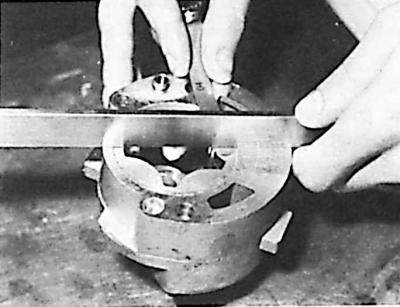

4. Using a feeler gauge and ruler, check the clearances between the oil pump elements.

5. Check the radial clearance between the gears.

6. Check the radial clearance between the rotor and the pump casing.

7. Check axial clearance.

8. Remove the oil pump gears and check their condition.

9. Insert the gears into the pump housing so that their designations are visible.

10. Install the oil pump cover.

11. Tighten the Torx bolts securing the oil pump cover.

12. Install the oil pump on the engine block. Other information regarding the technical characteristics, adjustment and repair of the engine is located in subsection 4.1 and subsection 3.1.3.1.

Visitor comments