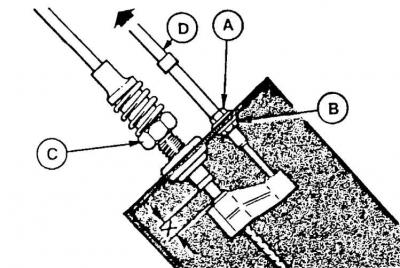

Adjustment of the kick-down cable in version 1

X \u003d 8 mm - control dimension A - kick-down cable tension adjustment nut, B - lock nut, C - accelerator pedal cable tension adjustment nut, D - cable sheath

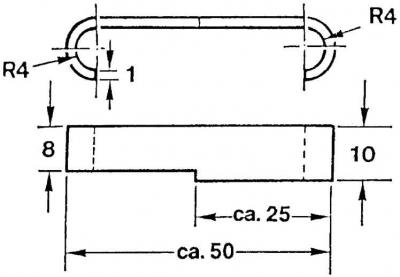

Kick-down Cable Adjustment Template Dimensions

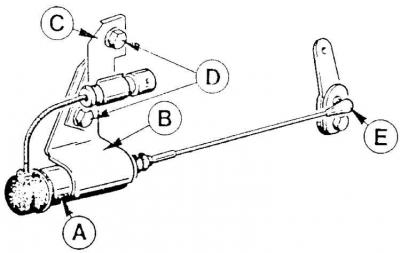

Adjustment of the kick-down cable in version 2

A - solenoid valve, B - housing, C - holder, D - fastening bolt, E - ball pin of cable connection

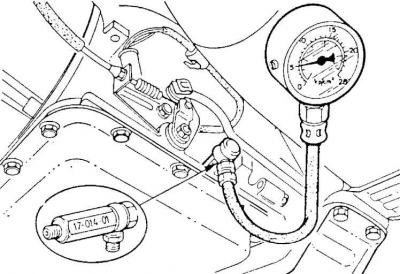

Checking the oil pressure in an automatic transmission

Removal and installation of a transmission

The method for removing and installing the gearbox is given in subsection 6.3.9.

Removal and installation of a cable of a reduction of transfers (rick-down mechanism)

The method for removing and installing the gear reduction cable is given in subsection 6.3.10.

Kick-down cable adjustment (1st execution version)

1. loosen the nut (A) (see fig. Adjustment of the kick-down cable in version 1) adjusting the cable tension of the kick-down mechanism and its locknut (IN).

2. Move the nut and locknut to the end of the thread.

3. Press the accelerator pedal all the way down and lock it in this position.

4. turn the nut (WITH) adjustment of the accelerator pedal cable tension until X = 10 mm (see fig. Adjustment of the kick-down cable in version 1).

5. For size check (X) it is recommended to use a template according to fig. Dimensions of the template for adjusting the kick-down cable.

6. While turning the nut (WITH) the spring resting on it and the sleeve cannot be rotated, as this would cause a change in size (X) while the car is moving.

7. Remove the template after adjustment.

8. Between sized elements (X), place the second side of the template according to fig. Kick-down Cable Adjustment Template Dimensions (8 mm wide) and release the accelerator pedal. The template should remain clamped by these elements.

9. Pull the shell by hand (D) kick-down cable in the direction of the arrow (see fig. Adjustment of the kick-down cable in version 1) in order to eliminate the play of the cable and hold the sheath in this position.

10. Screw the adjusting nut (A) until it stops against the casing plate, and then tighten its lock nut (IN).

Kick-down cable adjustment (2nd execution version)

1. With the gear lever in any position, turn on the ignition and depress the accelerator pedal all the way.

2. Hold the pedal in this position.

Attention! The engine cannot be started.

3. Turn the kick-down lever in the gearbox fully counterclockwise.

4. Move the solenoid valve forward until its cable is slightly taut.

5. Tighten the bottom of the two mounting bolts first (D) (see fig. Adjustment of the kick-down cable in version 2) to fix the solenoid valve, and then the top bolt; both bolts are tightened to a torque of 29–41 Nm.

6. Release the accelerator pedal.

7. Check adjustment - The kick-down lever should be able to turn fully counterclockwise when the accelerator pedal is fully depressed and the ignition is on. The control cable should be slightly taut.

Front planetary brake band adjustment

The method for adjusting the front planetary brake band is given in subsection 6.3.8.

Checking the oil level

The method for checking the oil level in an automatic transmission is given in subsection 6.3.3.

Checking the oil pressure while the gearbox is running

1. Connect a pressure gauge to the hole in the crankcase (see fig. Checking the oil pressure in an automatic transmission) after removing the cork.

2. Warm up the transmission to operating temperature. Measure the oil pressure while the engine is idling (correct values - see subsection 6.3.1).

3. If the oil pressure is too low, then check the oil level and the tightness of the hydraulic control housing, hydrokinetic transmission housing and oil pump.

4. If the oil pressure is too high, then check the idle speed, the tightness of the vacuum line of the gearbox regulator and its connection to the engine fuel system, the vacuum regulator of the gearbox and the hydraulic control unit in the gearbox.

5. Measure oil pressure during engine overload test via hydrokinetic transmission (with the vehicle stationary - the correct values are given in subsection 6.3.1).

6. If the pressure is too low, then check the vacuum lines, the acceleration valve, the hydraulic control unit, the front multi-plate clutch and the rear gearbox vacuum regulator.

7. If the pressure is too high, check the hydraulic control unit in the gearbox.

Engine overload test via hydrokinetic transmission

1. Connect a speed meter.

2. Tighten the hand brake lever and depress the service brake pedal.

3. Set the gearshift lever of the automatic transmission to the selected position (see subsection 6.3.1) and depress the accelerator pedal all the way.

4. Hold the pedal in this position until the readings of the engine speed meter stabilize (but not more than 2 seconds).

5. Number of turns in positions "DE"; "D" And "R" should be 2000-2900 rpm.

6. Move the gear lever to position "N".

7. Leave the engine idling for at least 15 seconds to allow the transmission to cool down and repeat the measurement at the next position of the gear lever.

Visitor comments