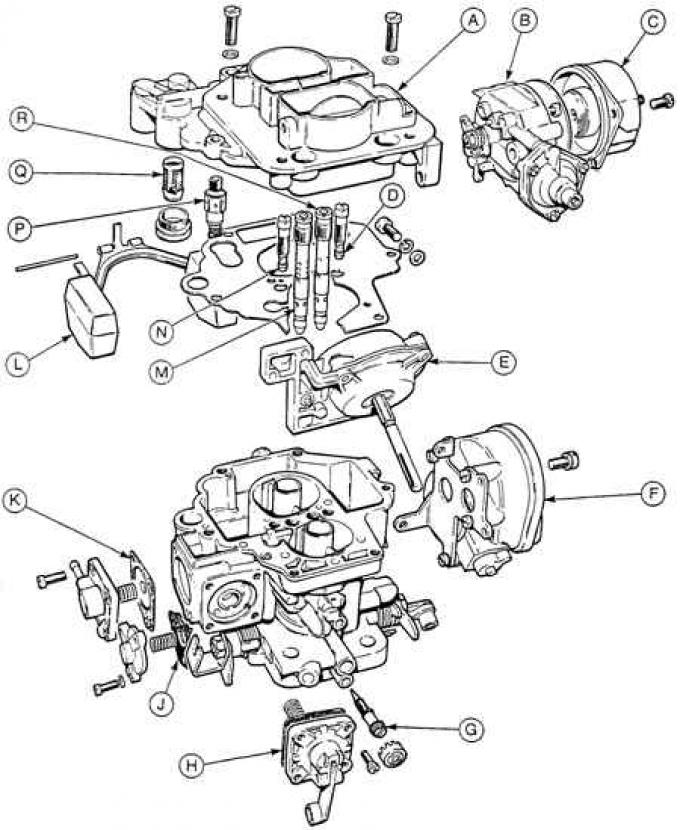

Elements of a two-chamber carburetor Weber 84 HF and 85 HF

A - carburetor cover, B - starter housing, C - starter cover with a bimetallic spring, D - idle jet of chamber II, E - second chamber vacuum regulator, F - idle speed adjustment stepper motor (only Weber 85 HF), G - idle mixture adjustment screw (CO content), H - accelerator pump diaphragm, J - full load enrichment device diaphragm (full power), K - medium-load enrichment diaphragm, L - float, M - emulsion tube of chamber I, N - idle jet of chamber I, P - needle valve, Q - strainer fuel filter, R - emulsion tube of chamber II

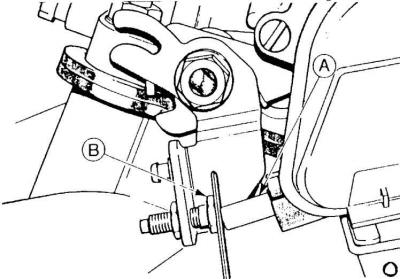

Installing a stepper motor for adjusting the idle speed of a Weber carburetor

A - stepper motor pusher,

B - restrictive bolt of the mixture throttle lever

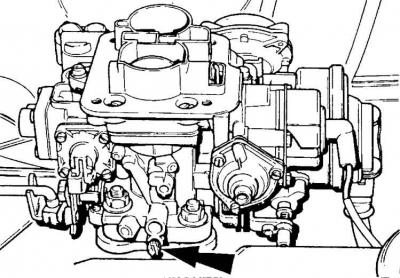

Weber 85 HF idle adjustment

The arrow shows the idle mixture adjustment screw.

The 1.6 dm3 LSD engine uses a two-barrel Weber 84 HF 9510 CA carburetor.

From model year 1985, the 2.0 dm3 NET engine uses a Weber 85 HF 9510 CA carburetor (in vehicles with manual transmission) or Weber 8 HF 9510 DA (in vehicles with automatic transmission). The design of the main elements of these carburetors is identical to the Weber 83 HF carburetors previously used in 2.0 dm3 engines.

The Weber 84 HF and 85 HF carburetors contain the following new elements:

- throttle valve mixture chamber II is controlled by the vacuum formed in the intake manifold;

- automatic starter is electrically heated (only 85 HF - engine 2.0 dm3);

- the idle speed is controlled by an electric stepper motor that drives the throttle valve I of the chamber. This engine receives control signals from the ESC II ignition control module (only 85 HF - engine 2.0 dm3).

Checking and adjusting Weber carburetors

Below is information regarding only checking and adjusting idle, as well as removing and installing a stepper motor for controlling the throttle valve of the mixture of the 1st chamber at idle speed of Weber 85 HF 9510 CA and DA carburetors used in engines 2.0 dm3 of type NET.

Removal and installation of a stepper motor and basic idle adjustment - motor 2.0 dm3 type NET

Removing and installing the idle speed control stepper motor is not particularly difficult.

1. After installation, basic adjustment should be made as follows.

2. Warm up the engine to normal operating temperature, turn off all current consumers and increase the engine speed twice to about 2500 rpm.

3. Insert a 1 mm thick feeler plate between the ends of the pusher (A) (see fig. Installing a stepper motor for adjusting the idle speed of a Weber carburetor) stepper motor idle adjustment and stop bolt (IN) mixture throttle lever. The engine idle speed should be 875±25 rpm.

4. If the number of revolutions is inappropriate, then loosen the locknut of the limit bolt (IN) and, turning this bolt, achieve the required value of the engine idle speed.

5. Remove the feeler plate and increase the engine speed at least twice to about 2500 rpm.

6. Reinstall the dipstick plate in the appropriate place and check that the engine idle speed is correct.

7. Remove the dipstick plate, check and, if necessary, adjust the CO content in the exhaust gases.

Mixture Adjustment (CO content) idling - engine 2.0 dm3 type NET

1. Warm up the engine to normal operating temperature.

2. Connect tachometer and exhaust gas analyzer.

3. Hold the engine speed at 3000 rpm for about 30 seconds and release the accelerator pedal.

4. After stabilization of the readings of both instruments, read the CO content at idle.

5. If necessary, adjust the CO content using the idle mixture adjustment screw (see fig. Weber 85 HF idle adjustment).

6. Place a seal on the idle mixture adjustment screw.

Attention! The idle speed is controlled by the ESC II electronic ignition control module, which controls a stepper motor that turns the throttle valve at idle. This unit is not adjustable.

Adjustment data for Weber carburetors

| Carburetor | 84 HF 9510 SA (1/ 2 camera) | 85 HF 9510 SA (1/ 2 camera) | 85 HF 9510 DA (1/ 2 camera) |

| Chamber diameter (mm) | 28/ 30 | 30/ 34 | 30/ 34 |

| diffuser diameter (mm) | 21/ 23 | 25/ 27 | 25/ 27 |

| Main fuel jet | 97/ 110 | 112/ 135 | 110/ 135 |

| Main air jet | 185/ 190 | 165/ 150 | 160/ 150 |

| emulsion tube | F59/ F22 | F22/ F22 | F22/ F22 |

| Fuel jet idling | 50/ 40 | 45/ 45 | 45/ 45 |

| Float installation - from the top edge (mm) | 6,0 ± 0,5 | 8,0 ± 0,5 | 8,0 ± 0,5 |

| Deviation of the starting air damper during operation of the vacuum regulator (mm) | 6,25 ± 0,25 | 9,0 | 8,0 |

| Fast idle speed (rpm) | 1700 ± 100 | – | – |

| Idle speed (rpm) | 800 ± 25 | 800* | 800* |

| CO content (%) | 1,0 ± 0,25 | 1,0 ± 0,25 | 1,0 ± 0,25 |

* The engine idle speed is controlled by the ESC II electronic ignition control module.

Visitor comments