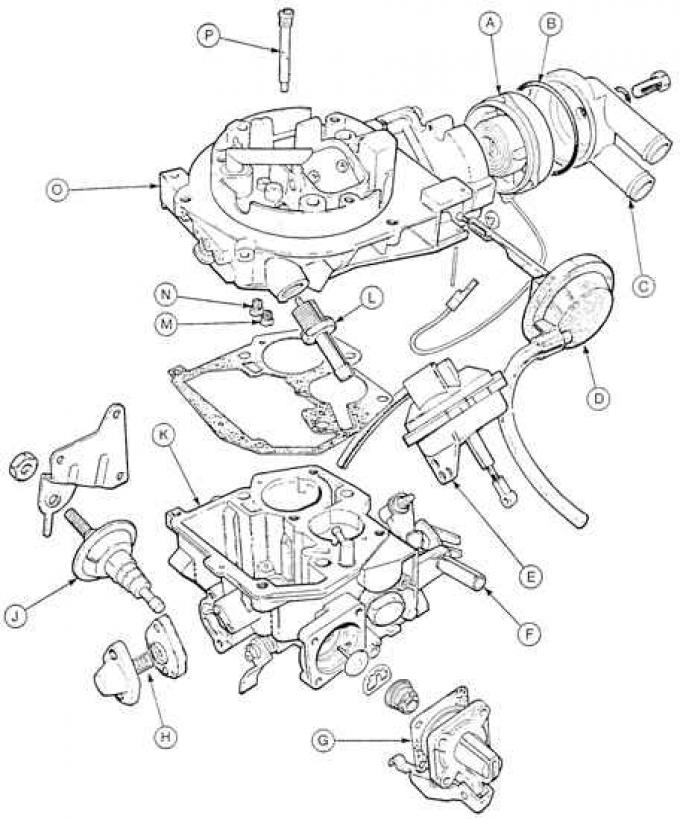

Elements of a two-chamber carburetor Pierburg 85 HF

A - bimetal spring housing, B - O-ring, C - automatic starter cover, D - starting throttle vacuum regulator, E - second chamber vacuum regulator, F - idle speed adjustment screw, G - accelerator pump, H - valve full load enrichment device, J - shock absorber (dash-pot) mixture throttle opening mechanism, K - carburetor body, L - fuel supply fitting, M - main fuel jet of chamber I, N - main fuel jet of chamber II, O - carburetor cover, P - idle jet

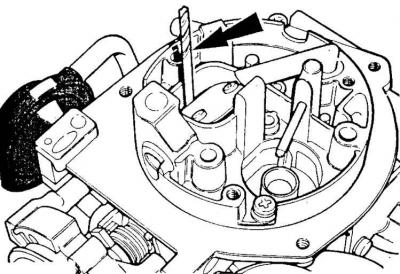

Measuring the choke opening of a Pierburg carburetor

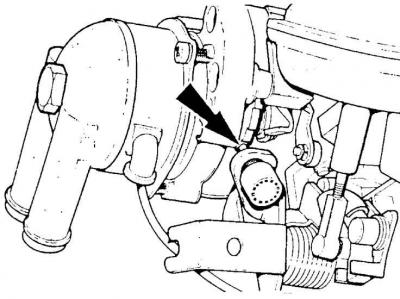

Pierburg carburetor fast idle speed adjustment

The arrow points to the fast idle adjustment bolt.

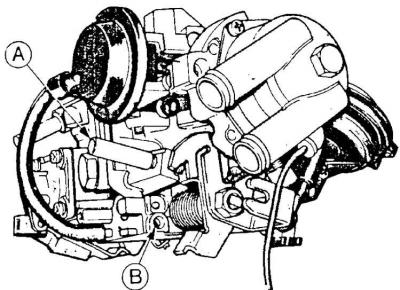

Pierburg carburetor idle adjustment

A - speed adjustment screw,

B - screw for adjusting the composition of the mixture

The 1.8 dm3 REB engine is equipped with a Pierburg 85 HF 9510 AB two-chamber carburetor with independent control of the throttle valves of both chambers, with an automatic starter and an accelerator pump.

Adjusting the opening of the starting air damper

1. Hold the mixture throttle in the partially open position and turn the fast idle cam over so that the fast idle speed adjustment bolt touches the maximum level of the stepped disc.

2. Using a feeler gauge or drill with a diameter of 3 mm, measure the width of the gap between the edge of the starting air damper and the wall of the carburetor chamber (see fig. Measuring the choke opening of a Pierburg carburetor).

3. If necessary, adjust the required clearance using the adjusting screw (socket wrench 2 mm).

Fast idle speed adjustment

1. Bring the engine up to normal operating temperature.

2. Check and, if necessary, adjust the idle speed and CO content.

3. Stop the engine.

4. Remove air filter.

5. Start the engine and leave it at idle.

6. Check whether the installation marks are located opposite each other on the starter cover and on the carburetor body.

7. Set the end of the fast idle speed adjustment bolt to the minimum level of the stepped disc by moving the throttle lever to do this (in the direction of increasing opening), turn the stepped disc accordingly and release the throttle lever.

8. Check the fast idle speed.

9. If necessary, correct it with the fast idle speed adjustment screw (see fig. Pierburg carburetor fast idle speed adjustment).

Idle adjustment

This adjustment is carried out with the engine warmed up to normal operating temperature and the current consumers switched off.

1. Before adjustment, check the tightness of the vacuum lines.

2. Connect the tachometer, check and, if necessary, adjust the idle speed by turning the screw (see fig. Pierburg carburetor idle adjustment).

3. Connect an exhaust gas analyzer.

4. Bring the engine speed up to 3000 rpm and hold it for about 30 seconds.

5. Release the accelerator pedal. The number of revolutions should be set at the previous level. The CO content will initially increase and should stabilize after 5–25 seconds.

6. 30 seconds after setting the speed, determine the CO content.

7. If necessary, adjust the CO content in the exhaust gases with a screw (IN) idle mixture composition.

Carburetor adjustment data Pierburg 85 HF 9510 AB

| diffuser diameter (1/ 2 camera) | 23/ 26 mm |

| Main fuel jet (1/ 2 camera) | 107,5/ 130 |

| Fuel jet idling | 45 |

| Air jet | 115 |

| Start throttle deviation | 3 mm |

| Start throttle bimetal spring adjustment | in accordance with the designations on the cover of the starter |

| Fast idle speed (support bolt at the minimum level of the disc) | 830±30 rpm |

| Idle speed | 800±20 rpm |

| CO content | 1,3 % |

Visitor comments