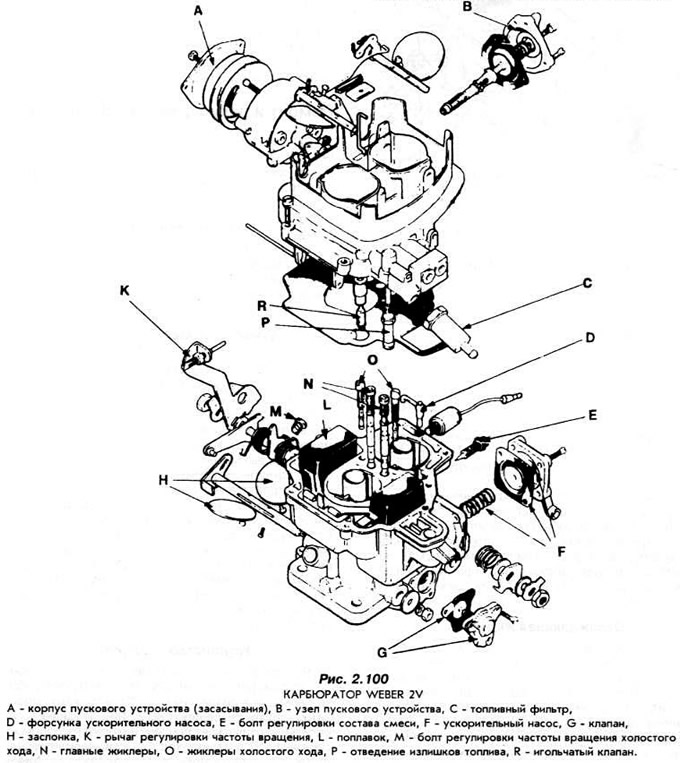

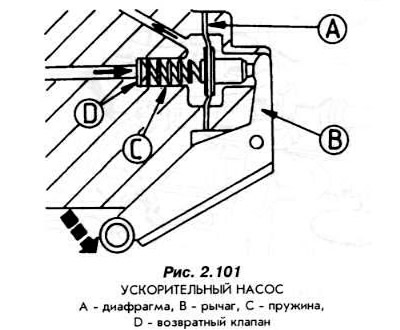

Accelerator pump

The accelerator pump feeds the engine with an additional portion of fuel during a sharp increase in vacuum (in case of quickly pressing the gas pedal to the stop). The pump device is shown in fig. 2.101.

Carburetor Vacuum Device

This device serves to slow down the closing of the damper when the gas pedal is quickly released. Due to the operation of the vacuum device, combustion in the engine under the described conditions proceeds relatively smoothly when an additional portion of fuel is supplied. Damper closing delay is also used to limit the release of harmful substances into the exhaust gases. On fig. 2.102 shows a diagram of a vacuum device.

The device contains a check valve, which is affected by the vacuum created in the intake manifold during engine operation. If the pressure on the gas pedal is released, the above check valve will hold the vacuum for some time, which will increase the time spent in the open state. As the vacuum decreases, the engine gently transitions to idle speed.

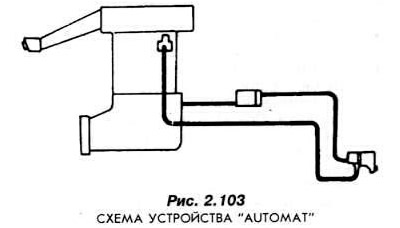

Device "Automat"

In vehicles with automatic transmission, the device "Automat" valid during transmission operation in the ranges "R", "D" And "L" as speed compensator (pic. 2.103). This means that if the automatic transmission is in one of the states "R" - reverse, "D" - moving forward or "L" - driving in urban conditions, and the car stops with the engine running - there is an automatic vacuum adjustment of the engine speed, which should make it impossible to start off spontaneously.

Starting device

The starting device is the so-called manual suction device. With its help, the air damper is covered. The vacuum increases and more fuel is delivered to the engine. The damper position can be changed within a certain range as a result of the action of the vacuum servomotor.

But after the end of the start-up phase, when the engine starts to work steadily, the vacuum established in the suction tube opens the damper, which subsequently remains stationary in this position (pic. 2.104).

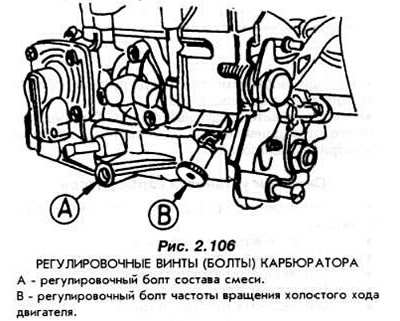

Engine idle speed adjustment

Warm up the engine until the radiator fan turns on.

Short circuit the electric wires of the fan in such a way that it does not turn off. To do this, remove the thermal switch connector and short-circuit both contacts of the connector plug with a piece of electrical wire (pic. 2.105).

Connect a tachometer and a device for measuring CO content in exhaust gases according to the instructions.

Remove the handset from the servomotor "fast" idle move.

Bring the engine speed up to 3000 rpm and let it run at this speed for 30 seconds.

After stabilization of the idling speed of the engine, take the readings of the tachometer and CO meter in the exhaust gases.

If the obtained data differs from the required ones, remove the seal from the adjusting screw (bolt) composition of the mixture. To do this, remove the air filter. Connect vacuum tube, reinstall air filter. The main crankcase ventilation duct must also be connected to the filter.

Turn both screws shown in fig. 2.106 and observe the readings of the tachometer and the device that measures the CO content in the exhaust gases. The adjustment should be completed after the tachometer and the device measuring the CO content show the required values. Place a new seal on the mixture adjustment screw.

Adjustment "fast" idle move

Warm up the engine to a temperature at which the radiator fan turns on.

Short circuit the electrical wires of the fan motor (pic. 2.105).

Connect a tachometer and a device that measures the CO content in the exhaust gases. Compare the obtained values with the required data. Adjust the idle speed and mixture if necessary.

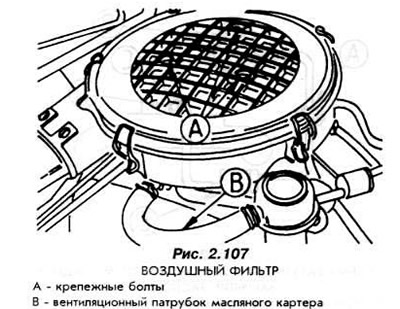

Remove the tube from the air filter (pic. 2.107). Remove the multi-pin connector of the intake air temperature sensor.

Disconnect the electrical wire from the shut-off valve and remove the air filter.

Pull the suction rod fully out and hold the trigger gate in the fully open position. Start the engine and read the engine speed from the tachometer.

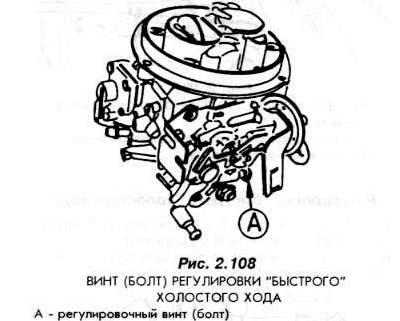

Adjust with screw if necessary (A) rotational speed (pic. 2.108).

Install the air filter. Connect all previously disconnected elastic tubes and electrical wires.

Visitor comments