The CFJ has an intake air temperature sensor (pic. 2.117).

This sensor is an electrical device and a change in ambient temperature causes a change in its electrical resistance. A coolant temperature sensor is installed in the engine cooling system (pic. 2.118).

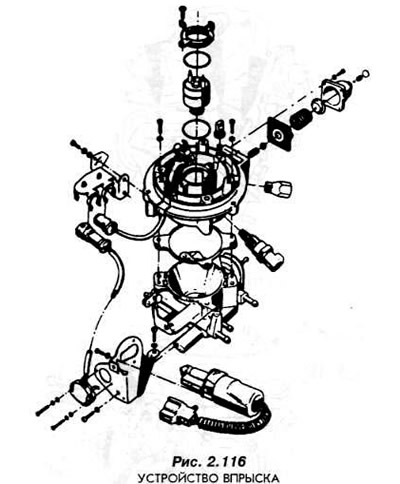

A heated lambda probe placed in the exhaust system detects the composition of the exhaust gases and transmits the corresponding signals processed in the microprocessor of the fuel injection control device. The vacuum gauge is located on the intake manifold (pic. 2.119).

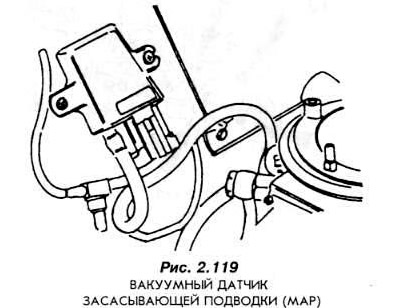

It is connected to the collector with an elastic hose. The injection control system also receives signals about the current driving speed. Speed sensor mounted on gearbox (pic. 2.120).

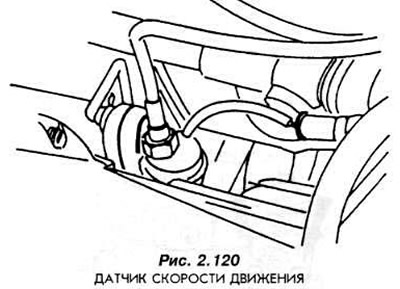

The current damper position is monitored by a potentiometer (pic. 2.121), that sends signals to the CFJ device.

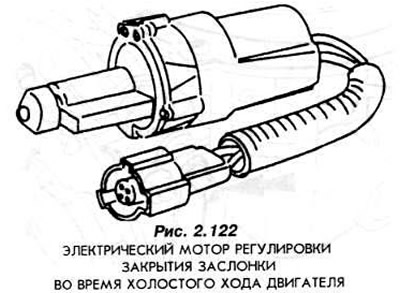

The idling speed is regulated by changing the position of the stop, rearranged by the electric motor (pic. 2.122).

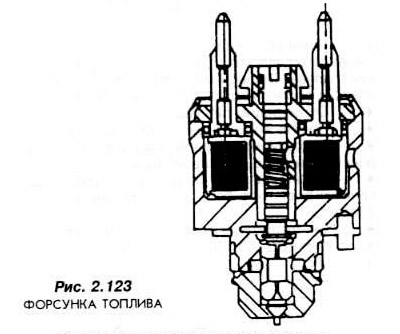

On fig. 2.123 A fuel injector is shown in section.

Visitor comments