Note: Replacing most items requires a complete disassembly of the entire EFI system. To determine what specifically needs to be disassembled, carefully read the section and those paragraphs that pertain to replacement parts.

Intake Duct/Throttle Body Assembly

Note 1: If you are replacing the gasket between the intake duct/throttle body, you will not have to remove the various parts attached to the throttle body. Remove the entire assembly as recommended below.

Note 2: Specific information for 1991 four-cylinder engines is given in paragraphs 15 to 24 in section 14.

Disassembly

1. Unscrew the fuel filler cap.

2. Relieve pressure in the fuel system (see section 2).

3. Disconnect the negative battery cable.

4. Loosen the hose clamps and disconnect the air cleaner connecting tube, which is located between the air cleaner and air throttle bodies.

5. Disconnect the electrical connector from the throttle position sensor (TP) auxiliary air valve, air temperature sensor (ACT) and electronic converter of the exhaust gas afterburning system (EGR).

6. Disconnect the throttle cable from the throttle connection (see section 9).

7. Tag and then disconnect the main vacuum line branch, pressure regulator, and MAP sensor vacuum line from the vacuum line branch. Disconnect the vacuum tube from the EGR valve.

8. Disconnect the PCV hose from the PCV valve (see chapter 1). On four-cylinder engines, remove the pressure and outlet pipes.

9. Unscrew and disconnect the EGR pipe from the EGR valve (see chapter 6). On a four-cylinder engine, remove the upper intake manifold support brackets.

10. On V6 models, remove the alternator support bracket nut from the stud on the far right end of the intake assembly (from the passenger seat), loosen the nut on the other end of the bracket and remove the support bracket (see chapter 5).

11. Unscrew all bolts of an inlet air duct, including also a hairpin mentioned in the previous paragraph (see picture). Remember that on V6 models, bolts of different lengths are used (two long, two medium and two short) Bolts should be screwed into the holes from which they were unscrewed.

12. Remove intake duct/throttle body assembly (see pictures).

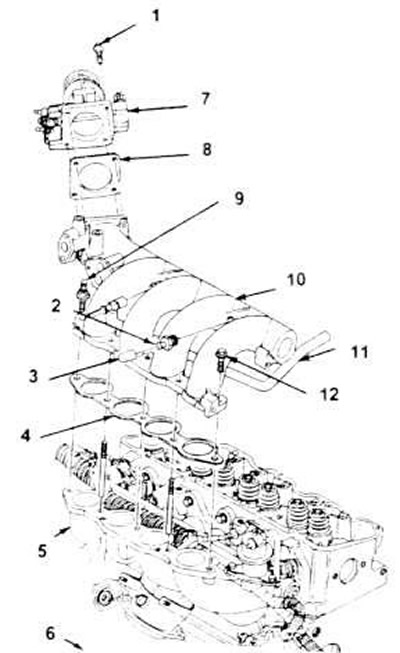

13.12, b. 3D view of upper intake manifold and throttle body (1991 four-cylinder engine).

1. Bolt М6х1х30 (4 pieces).

2. Nipple.

3. Cover.

4. Gasket.

5. Lower intake manifold assembly.

6. Front of the engine.

7. Throttle body assembly.

8. Gasket.

9. Bolt - stud M8x1.25x35x12.

10. Upper intake manifold assembly.

11. PCV hose.

12. Bolt M8x1. 25x35 (4 pieces).

12. Remove intake duct/throttle body assembly (see pictures).

13. Remove and discard the old gasket.

13. Remove and discard the old gasket.

Installation

14. Clean and check the adjacent surfaces of the throttle body and lower intake manifold. Both surfaces must be clean and flat.

15. Clean and oil the threads of the manifold studs.

16. Install a new gasket.

17. Using the guide pins as a guide, secure the throttle body assembly to the lower intake manifold.

18. Screw in six bolts (two long, two medium, two short) each into its own hole and tighten them to the required torque.

19. Assembly is carried out in the reverse order of disassembly.

Secondary air valve assembly

Disassembly

20. Pull out the auxiliary air valve connector (see picture).

21. Loosen the snow shield bolts and detach the snow shield (if he is).

22. Unscrew the two fixing screws.

23. Remove the secondary air valve and gasket. Discard the old gasket.

Installation

24. Make sure that the mating surfaces of both the throttle body and the valve gasket are clean.

25. Install the gasket on the surface of the throttle body and replace the auxiliary air valve. Tighten the fixing screws.

26. Installation is carried out in the reverse order of disassembly.

Throttle position sensor (TR)

Withdrawal

27. Pull out the throttle position sensor connector (see picture).

28. Scratch marks on the throttle body and on the throttle position sensor to accurately align their relative position during installation.

Note: The TP sensor is not adjustable so these marks are very important.

29. Unscrew the two locking screws of the throttle position sensor.

30. Remove the throttle position sensor.

Installation

31. Make sure the sensor's pivot tabs are oriented correctly and the red gasket is inside the connector housing. Set the pivot tabs to position over the throttle shaft vane, then rotate the throttle position sensor (TPS) clockwise until it is in place.

Caution: installing the sensor in any other way may increase the idle speed.

32. Align the marks on the throttle body and the sensor on the throttle body with two set screws.

33. Installation is carried out in the reverse order of disassembly.

Fuel rail

Withdrawal

34. Remove the intake air duct throttle body (see above).

35. Disconnect the vacuum lines from the fuel pressure regulator.

36. Using a small screwdriver, carefully remove the fuel injector electrical connectors (see picture).

37. Using a special Ford spring-lock tool (3/8" front and 1/2" rear) or its equivalent, disconnect the tips of the fuel pipelines, as well as the fuel supply and return pipelines (see section 3).

38. Remove the fuel injector manifold mounting bolts (see picture).

39. While lifting and slightly shaking the fuel guide, carefully separate the guide assembly and fuel injectors.

40. Rules for replacing injectors, O-rings or fuel pressure regulator, see below.

Installation

41. Lubricate all lower O-rings with clean engine oil.

42. Carefully reinstall the fuel rail and injector assembly into the lower intake manifold, alternately on each side. To make sure the O-rings are in place, push down on the top of the guide.

43. While holding the rail assembly in place, hand-tighten the bolts, alternately on each side, then tighten them.

44. Installation is carried out in the reverse order of disassembly.

Fuel injectors

Disassembly

45. Remove the intake air duct throttle body (see above).

46. Remove the fuel manifold assembly (see above).

47. Remove each of the nozzles, while pulling the nozzle at the same time rotate it from side to side (see picture).

48. Carefully pry up with a small screwdriver to remove the O-rings (see picture).

Caution: Handle the injector and fuel manifold with extreme care to prevent damage to sealing surfaces and fuel spray holes, which are very sensitive.

49. Make sure the nozzle caps are clean, not damaged or dirty.

Installation

50. Nozzles are installed by turning and pushing movements.

51. Installation is carried out in the reverse order of disassembly.

Fuel pressure control

Withdrawal

Note: If you have the special tool, it is not necessary to remove the fuel rail assembly to remove the pressure regulator. Otherwise, this node must be removed.

52. Remove the fuel filler cap.

53. Relieve the pressure in the fuel system (see section 2). On four-cylinder models, remove the 3 screws and remove the fuel rail screen.

54. Disconnect the vacuum line from the pressure regulator (see picture).

55. If a right hand tool is available, remove the three Allen screws from the underside of the pressure regulator base plate.

56. If there is no necessary tool, then first remove the fuel rail assembly (see above), and then unscrew the screws (see picture).

57. Remove the pressure regulator assembly, gasket and O-ring Replace the ring and gasket.

Installation

58. Make sure the sealing surfaces of the pressure regulator and fuel rail are clean. When using the scraper, be careful not to damage the working surfaces of the regulator and the inlet piping gasket.

59. Lubricate the pressure regulator O-ring with clean oil.

60. Install a new o-ring and gasket on the regulator.

61. Place the fuel pressure regulator on the fuel rail assembly and tighten the three mounting screws.

Visitor comments