Special tool

| Axle puller 204-226 (16-092) |

| Adapter for 204-226 204-226-01 (16-092-01) |

| Hammer with moving hammer 205-047 (15-011) |

| Ball joint puller 211-020 (13-006) |

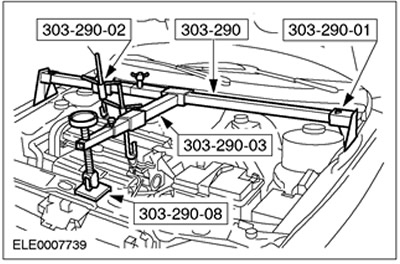

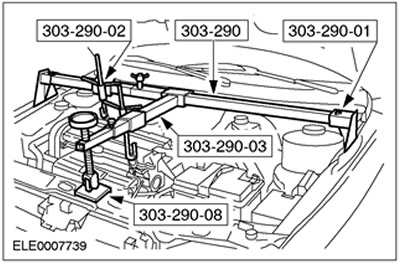

| Engine support beam 303-290A (21-140) |

| Adapter for 303-290A (21-140) 303-290-01 (21-140-01) |

| Adapter for 303-290A (21-140) 303-290-02 (21-140-02) |

| Adapter for 303-290A (21-140) 303-290-03 (21-140-03) |

| Adapter for 303-290A (21-140) 303-290-08 (21-140-08) |

General equipment:

- Fixing clamps

- Jack for gearbox

- wooden block

Withdrawal

1.

NOTE: The location of the engine mounts and engine mounts in the description corresponds to the view from the automatic transmission to the engine.

Move the gear selector to position "D".

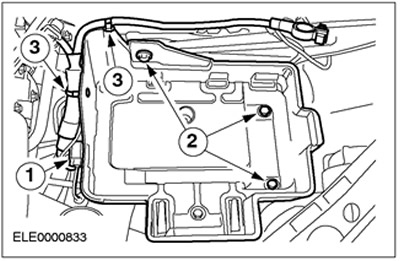

2. Remove the battery. See Section 414-01 for more information.

3. Remove the battery tray.

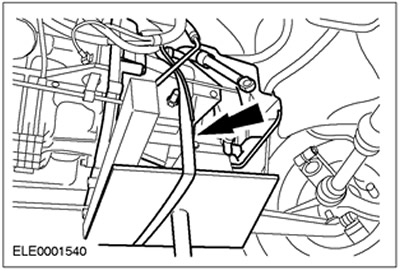

- 1. Release the plug from the clip on the battery tray.

- 2. Turn out bolts of fastening.

- 3. Disconnect the wiring harness from the battery tray.

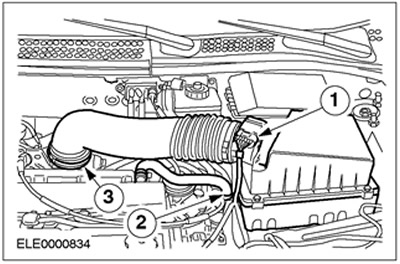

4. Remove the air filter housing.

- 1. Disconnect the electrical connector of the mass air flow sensor (MAF).

- 2. Disconnect the crankcase ventilation hose from the air filter.

- 3. Disconnect the intake hose from the throttle body.

5. Remove the air filter inlet pipe.

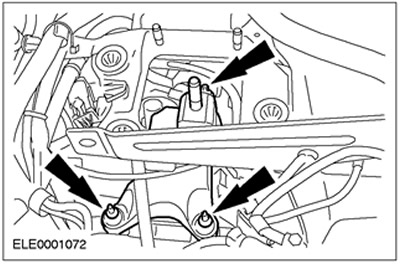

6. Disconnect plug connectors from selector lever assembly.

- 1. Disconnect the transmission range sensor electrical connector (TR).

- 2. Disunite the shtekerny socket of an automatic transmission in the block with the leading bridge.

7. Disconnect the selector lever cable from the selector lever assembly.

8. Disconnect the electrical connector of the turbine shaft speed sensor (TSS)

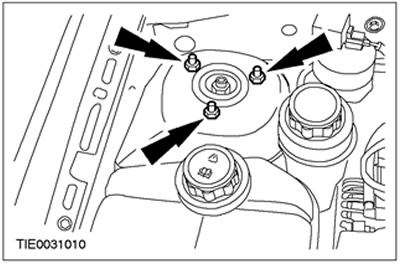

9. Loosen the nuts of the upper support of the suspension strut assembly with the spring five turns (at both sides).

10. Disconnect the oil filler pipe and the selector lever cable bracket from the transaxle.

11. Remove the left front wheel assembly with tire. See Section 204-04 for more information.

12. Remove the right engine mount.

13. Remove the heat shield.

14.

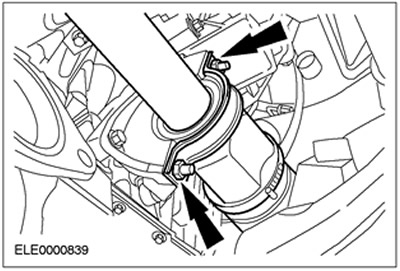

CAUTION: Excessive bending of the flexible exhaust pipe can damage it. Support the flexible exhaust pipe with a support clamp or a suitable cotter pin.

Remove the flexible exhaust pipe.

15.

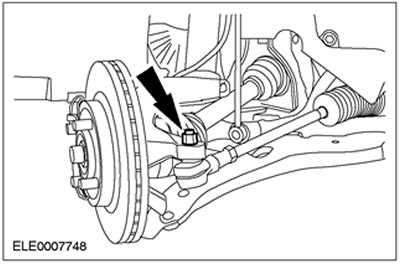

CAUTION: Leave the tie rod end nut in place to prevent damage to the ball joint stud.

Loosen the left tie rod end nut.

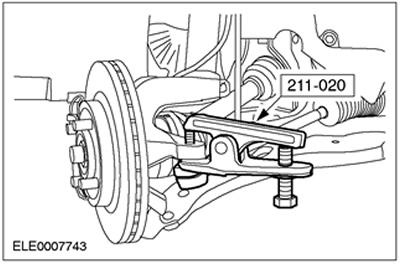

16.

CAUTION: To prevent damage to the ball joint seal, cover it with a piece of soft cloth.

Using the special tool, disconnect the tie rod end from the steering knuckle.

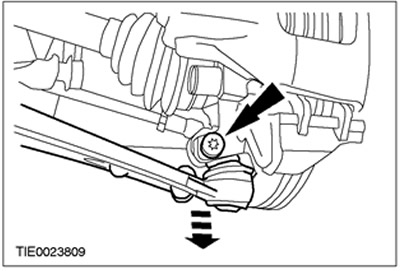

17. Disconnect the lower arm from the steering knuckle (at both sides).

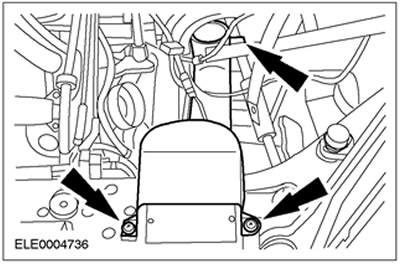

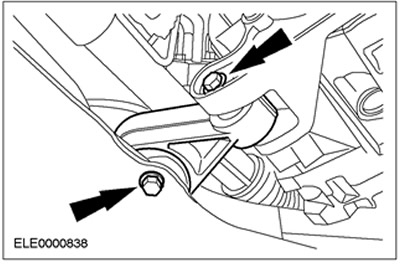

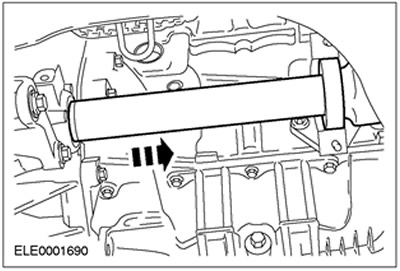

18. Remove a cover of the intermediate bearing of the right semiaxis.

- Discard the intermediate bearing cap and locknuts as they are no longer needed.

19.

CAUTION: Support axle shaft. The inner hinge should not be tilted more than 18 degrees. External hinge - at an angle exceeding 45 degrees.

CAUTION: Be careful not to damage the axle shaft oil seal.

NOTE: Shut off the transaxle to prevent oil leakage or dirt ingress.

Disconnect the right axle shaft from the gearbox in the block with the driving axle and fix it to the side.

- Allow the oil to drain into a suitable container.

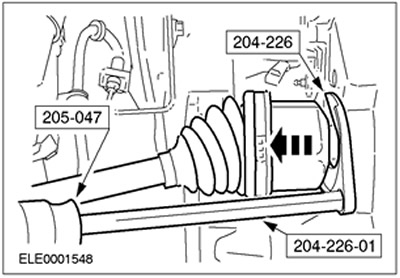

20.

CAUTION: Support axle shaft. The inner hinge should not be tilted more than 18 degrees. External hinge - at an angle exceeding 45 degrees.

CAUTION: Be careful not to damage the axle shaft oil seal.

NOTE: Shut off the transaxle to prevent oil leakage or dirt ingress.

Using the special tools, disengage the left axle shaft from the transaxle and secure it out of the way.

- Discard the spring ring for attaching the cantilever part of the axle shaft as it is no longer needed.

- Allow the oil to drain into a suitable container.

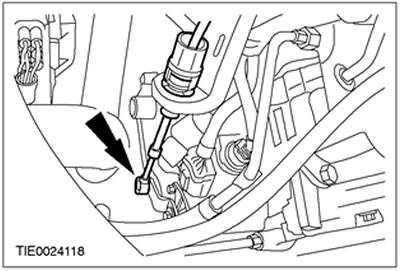

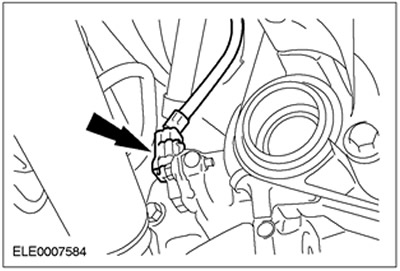

21. Disconnect the electrical connector of the secondary shaft speed sensor (OSS).

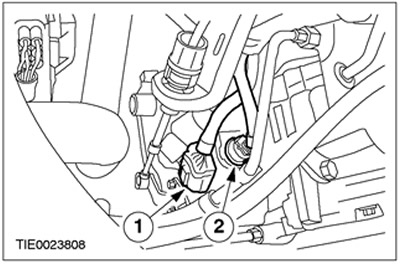

22.

CAUTION: Do not disconnect the coupler from the transaxle case.

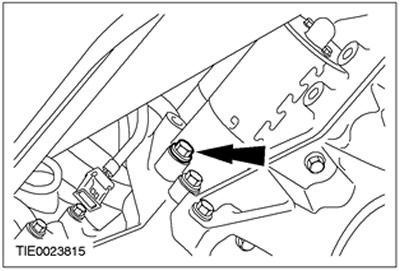

Disconnect the oil cooler pipes from the gearbox in the drive axle block.

23. Lower the car.

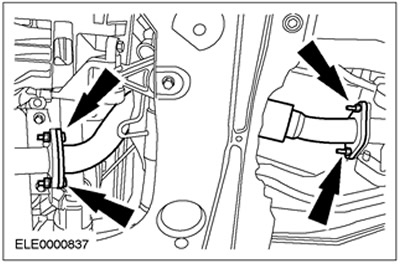

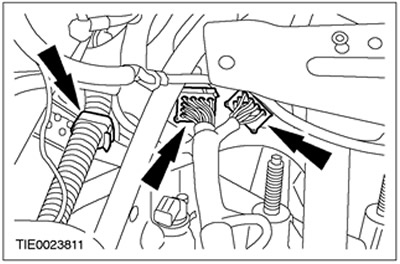

24. Install special tools.

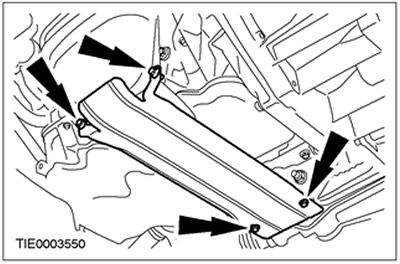

25. Remove the rear engine support assembly with the gearbox in the block with the drive axle.

26. Using the special tools, lower the engine/transaxle assembly.

27. Remove the mounting bracket for the rear engine mount assembly with the gearbox in the block with the drive axle.

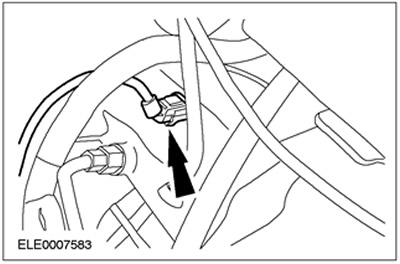

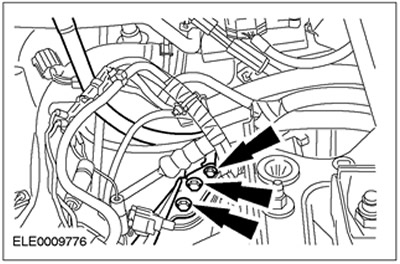

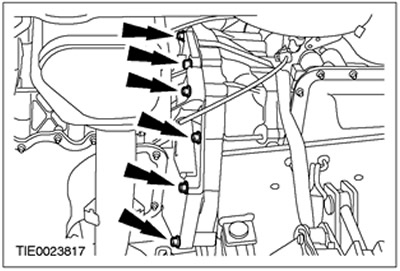

28. Disconnect the wiring harness from the gearbox in the block with the drive axle.

- Disconnect the clamp.

- Disconnect electrical connectors.

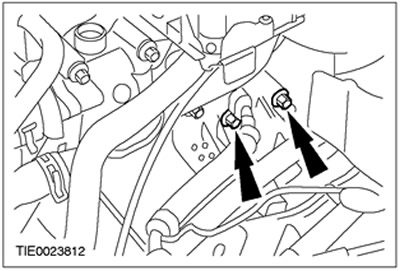

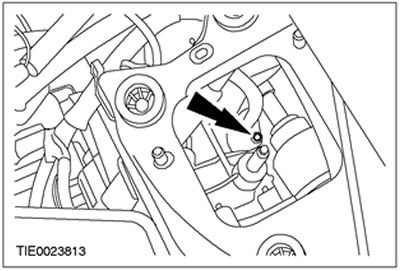

29. Turn out bolts of fastening of a starter.

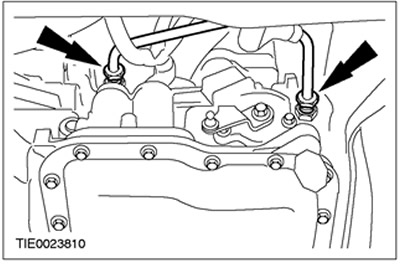

30. Turn out the top bolts of fastening of a transmission in the block with the leading bridge.

31. Remove the filler oil line.

32. Raise and support the car. See Section 100-02 for more information.

33.

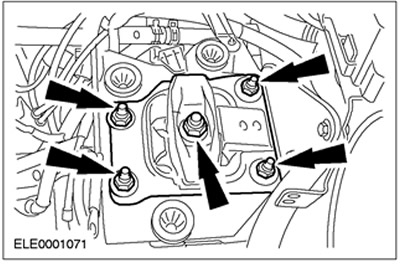

NOTE: The engine must be rotated to gain access to the torque converter mounting nuts.

Disconnect the torque converter from the flywheel (four nuts). Remove the cover (in the presence of).

34. Disunite electric connections of a starter.

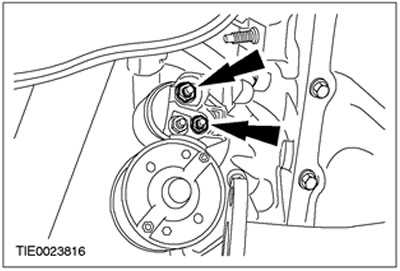

35. Remove the starter.

36. Using an appropriate gearbox jack and wooden block, support the gearbox in the drive axle assembly.

- Secure the gearbox to the drive axle block using the fixing clamps.

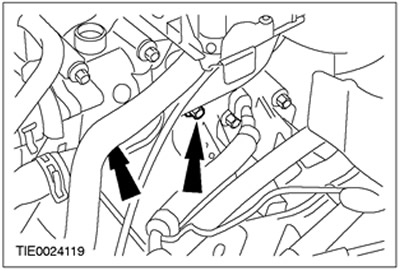

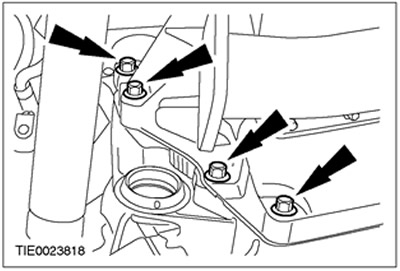

37. Turn out the left bolts of fastening of a transmission in the block with the leading bridge.

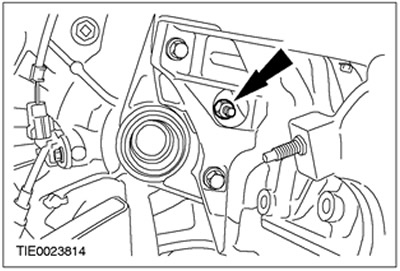

38. Turn out the right bolts of fastening of a transmission in the block with the leading bridge.

39.

CAUTION: Make sure the torque converter is secured.

NOTE: To facilitate installation, note the position and number of pins on the motor flange.

Remove a transmission in the block with the leading bridge.

Visitor comments