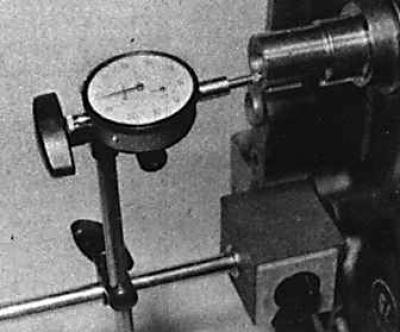

Checking the axial play of the crankshaft with a dial gauge

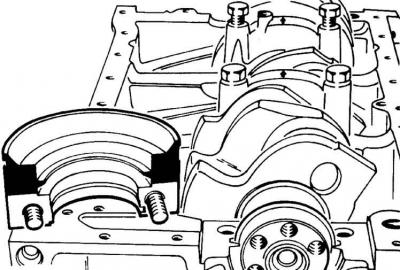

1. Wipe the bearing shell locations on the crankshaft and install the upper main bearing half shells.

2. Clean the locations of the main bearing shells and install the shells in the caps. If old liners are installed, make sure that they are installed in their original places.

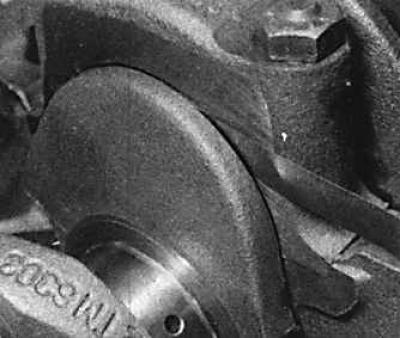

3. Apply a small amount of grease to both sides of the #3 main bearing to hold the thrust washers in place.

4. Position the upper halves of the thrust washers in the grooves on the sides of the No. 3 main bearing with the grooves outward, with the tongue in the groove.

5. Lubricate the crankshaft main bearing journals and main bearing shells with engine oil.

6. Install the rear main bearing seal to the crankshaft.

7. Carefully lower the crankshaft into the crankcase.

8. Apply a thin layer of sealant to the mating surfaces of the crankcase and rear main bearing cap.

9. Lubricate both sides of the #3 main bearing cap to hold the thrust washers. Install the thrust washers with the grooves outward, the tongue should be in the groove.

10. Install the main bearing caps with the arrows on the caps pointing towards the front of the engine.

11. Gradually tighten the main bearing bolts to the correct torque, except for the No. 3 bearing bolts, they should only be hand-tightened. Press the crankshaft to move it all the way back, then slowly push it to move it all the way forward, hold it in this position, and tighten the No..

12. Press the rear crankshaft seal against the main bearing. When it is finally installed, protect the edges of the O-ring with masking tape.

13. Using a set of feeler gauges, measure the end play of the crankshaft; the feeler gauge is installed between the crankshaft journal and the thrust washers. The clearance must be within the values specified in subsection 3.3.1. To adjust the gap, thrust washers of various thicknesses can be installed.

14. Rotate the crankshaft to see if it is sticking. If the shaft turns very tight or sticks, it is necessary to disassemble and carefully check.

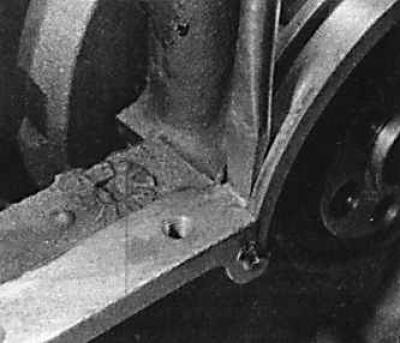

15. Lubricate the seals on the rear main bearing cap (black) sealant and install.

16. Use a flat blade screwdriver or similar tool to install the seals. The seals are installed with the rounded face towards the bearing cap.

Visitor comments